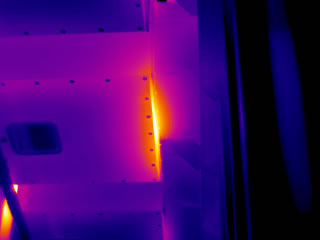

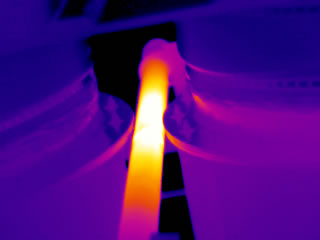

Inductive Heating Hotspots

Sponsored by:

Tip written by: Infraspection Institute

Loose connections, overloading and imbalanced loads cause overheating of components within an electrical system. Depending upon construction and operation of the electrical system, a perplexing and possibly serious condition called inductive heating can cause non-current carrying components to overheat.

Images Courtesy Brady Infrared Inspections, Inc.

As current flows through an electrical circuit, a magnetic field forms around the conductor. When current flow is high, a strong magnetic field can develop and extend for several inches around the subject conductor(s). If ferrous materials such as steel are positioned within this magnetic field, they can heat up even though they are not part of the circuit.

Inductive heating can occur on bus supports, cable tray fasteners, bushing skirts and switchgear enclosures. Affected components can become hot enough to cause significant heat damage or even skin burns. The temperature of the affected component will depend upon the strength of the magnetic field, and the composition and location of the affected component.

Because inductive heating can cause components to reach temperatures of over 400ºF, thermographers should pay particular attention whenever combustible materials or dielectric insulation are located near, or in contact with, an inductively heated item.

Infrared inspection of electrical distribution systems is one of the many topics covered in the Level I Infraspection Institute Certified Infrared Thermographer® training course. For information on thermographer training or to obtain a copy of the Standard for Infrared Inspection of Electrical Systems & Rotating Equipment, visit us online at: www.infraspection.com or call us at 609-239-4788.

Advertisement