Infrared Inspection of Breaker Control Cabinets

Sponsored by:

Infrared Inspection of Breaker Control Cabinets

Tip provided by: Brady Infrared Inspections, Inc.

Infrared inspections of electrical systems often include high visibility equipment such as substations, switchgear and motor controllers. In this Tip we discuss several critical items that are often overlooked during infrared inspections.

Perhaps one of the most overlooked pieces of equipment during an infrared inspection of electrical substations and indoor electrical switchgear is the control cabinets located beneath breakers in outdoor substations and above or on the side of rack-in breaker bays on 480V and higher indoor switchgear.

Equipment inside these cabinets is comprised of both AC and DC current and includes relays, conductor terminal connections, current transformers, breakers, and fuses. The primary function of this equipment is to activate the trip mechanism of a breaker if voltage or current conditions fall outside the specified trip settings.

Connection failures and other heat related damage to equipment inside these cabinets can cause a breaker to trip resulting in widespread power outage throughout a community and/or a facility. Given the vital importance of this equipment, it should be on every thermographer’s inventory list to inspect.

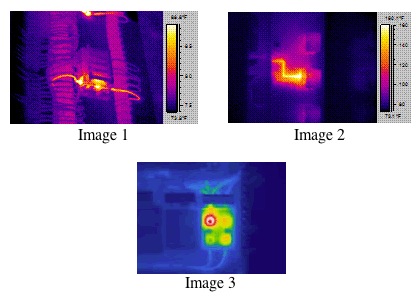

Below are a few examples of thermal problems that can be detected in these cabinets:

1) Image 1 shows internal heating on a breaker,

2) image 2 shows heating of a impregnated ribbon bus on a relay circuit board, and

3) image 3 shows heating on a plug-in fuse responsible for the switchgear cabinet heater

Advertisement