Normal Hot Spots in Electrical Systems

Sponsored by:

Normal Hot Spots in Electrical Systems

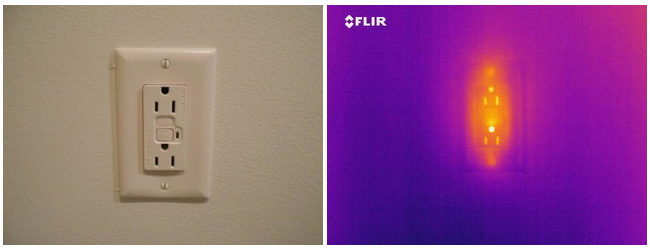

In general, hot spots within electrical systems are indicative of problems such as loose connections or overloaded circuits. For some electrical components, high temperature operation is normal and an infrared imager can be used to help ensure that these devices are functioning.

During a routine infrared inspection of electrical distribution systems, similar components under similar load are compared to each other. Items appearing inexplicably hot are reported as exceptions to be further investigated and appropriately repaired. For components that normally operate at elevated or high temperature, a lack of heat may be indicative of an exception.

Capacitors used for power factor correction are good examples of components that are normally warm. Properly functioning capacitors should operate above ambient temperature and their casings should be uniform in temperature when compared to similar units under similar load.

Thermal overload relays are found in many motor controllers. The elements of these relays, often called heaters, may operate at high temperature when the circuit is under load. When compared to adjacent phases, these elements should be similar in temperature with no pronounced hot spots.

Electric strip heaters are used to control humidity within switchgear enclosures. Switchgear heaters usually operate at very high temperatures and their operation can easily be verified with an infrared imager. Cold strip heaters may be indicative of a failed element, improper control settings, or a de-energized control circuit.

The above are just three examples where elevated temperatures are normal. Thermographers should always be on the lookout for cold spots that may be indicative of problems in addition to hot spots traditionally associated with exceptions.

Infrared inspection of electrical distribution systems is one of the many topics covered in the Level I Infraspection Institute Certified Infrared Thermographer® training course. For information on thermographer training or to obtain a copy of the Standard for Infrared Inspection of Electrical Systems & Rotating Equipment, visit us online at: www.infraspection.com or call us at 609-239-4788.

Advertisement