Ed Kochanek, Director of Sales, Key Account Manager

and David Lee

FLIR Systems, Inc.

22 Overlook DriveWoolwich, NJ 08085Ph: 866-379-4022Mobile: 609-932-8795www.flir.comAbstract

For over 30 years airborne thermal imaging systems have provided a unique perspective for a number of applications. In the past, thermal imaging systems were expensive and were limited to use with either helicopters or fixed-wing aircraft. The recent introduction of affordable, unmanned aerial vehicles (UAVs), also known as drones, combined with lightweight thermal imagers has made aerial thermal imaging more affordable than ever. While the drone revolution has been underway for a number of years, the foretold expansion into commercial markets took off in earnest in the last 12 – 18 months.

This paper and presentation will discuss the many uses of thermal imaging from the air. We will discuss search and rescue, utility and building applications and how far away you can be to see someone or something. We will also discuss the latest trends and what to look for in a thermal imager when you are above your target.

Applications

Commercial Roof Inspections

As with many of the applications we’ll discuss, one of the primary benefits of inspecting a flat commercial roof with a drone is simply one of efficiency. A large roof deck that could take hours, if not nights, to walk and inspect, can be done with a drone in a matter of minutes. A common technique for roof inspection is to fly high enough (within legal limits) to image the entire roof, then fly a methodical pattern at a lower altitude to gather detailed imagery of areas with potential issues. When conducted in accordance with ASTM C1153, fasteners, deck structures, and possible water or insulation problems are all readily visible.

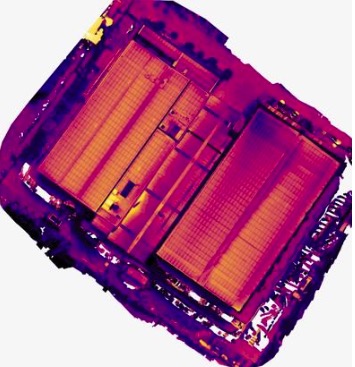

Solar Field Inspections

This is another area where a large solar field can be inspected in a fraction of the time (and cost) from the air, compared to what’s required for handheld inspections. Large areas can be eliminated from consideration for terrestrial inspection right away, while efforts are concentrated on areas with known anomalies. In addition to the added efficiency gained by inspecting large solar fields by a thermal-equipped drone, aerial inspections also permit technicians to monitor possible failures over time. While a thermal drone can easily detect cell level defects, finding entire strings that are offline are more commonly going to be the issues that are promptly addressed as they’re much more likely to impact the efficiency of the entire installation.

However, by tracking cell defects across numerous inspections, technicians can determine if the problem is localized, spreading, or even going away. The last of these is often the result of dirt or debris on the cell that is creating a “false positive” – and one that will disappear after the next good rain storm. Solar field inspections are greatly aided by creating orthomosaics of hundreds of images that are stitched together into a single image. This aids not only in the rapid communication of fault locations to technicians, but helps operators track those cell defects over time by comparing multiple orthomosaics side by side.

Power Generation & Distribution

quickly with thermal-equipped drones.

Similarly, distribution lines that are in rugged and hard to reach areas can be safely inspected by drones at a fraction of the cost of using manned helicopters. While current FAA regulations limiting beyond visual line of sight (BVLOS) operations are keeping utilities from taking full advantage of this technology, there is movement in a positive direction, and the enormous safety and cost savings of drone technology can already be realized.

Oil & Gas

This application falls into two areas: refinery inspection and pipeline inspection. Inspecting refineries by using drones equipped with optical gas imaging (OGI) sensors is fast and effective. Recent technological innovations even allows operators to quantify leaks remotely, keeping them from running afoul of regulators.

Pipeline inspection done with fixed wing drones that have much greater endurance than their multirotor counterparts combines many of the benefits already discussed. Their operations cost a fraction of manned aircraft, they take multiple overlapping images that can be stitched together into an orthomosaic to give managers and engineers a broad overview of their infrastructure in addition to detailed images of faults, and possible trouble spots can be analyzed over time to provide insight into the life cycle of the components involved.

Agriculture

While not an area many thermographers would consider, drone use in agriculture is one of the fastest growing segments in the industry. Using Multispectral (NDVI) cameras to quantify crop stress is the most common use, but thermal cameras are used to detect problems with central pivot irrigators, and to diagnose issues with irrigation ditches – even under ground. Ranchers are also using thermal drones to keep track of herds ranging in remote areas, and to find animals that may have become separated from the herd and stuck in remote draws or canyons.

Public Safety

search and rescue public safety operations are vital to

community well- being.

Conclusion

Opportunities for trained, experienced thermographers are plentiful, and more than justify adding drone operation to your professional toolkit. As drone hardware becomes more and more of a commodity, barriers to entry get lower, and their operation becomes more automated, drone operation will continue to migrate away from being the purview of drone service providers and towards those with the specialized skills and experience necessary to analyze the sensor data they collect. An aerial drone thermal image of a commercial roof, solar panel, or substation is just a pretty picture without the knowledge to properly interpret it.