Pay Attention or Pay a Price

By Mike Henneker, Member AUSPTA Management Committee

For professional thermographers, conducting a thermography survey is a proven, cost effective

way of early identification of electrical faults and, therefore, saving the asset owner downtime,

lost production, anxiety & frustration. Unfortunately, there are times when due attention has

not been paid to the thermography survey report.

During a recent annual thermography

survey of a production plant a 1600

amp MCCB was identified with

abnormal thermal patterns internally and

on the centre (white) phase. This MCCB had

previously been replaced around 2 years

before this survey, after being identified

with similar abnormal thermal patterns and

excessive operating temperatures. Initially

we identified that the MCCB was not

overloaded with the load being in the 1200

– 1400 amp range when measured.

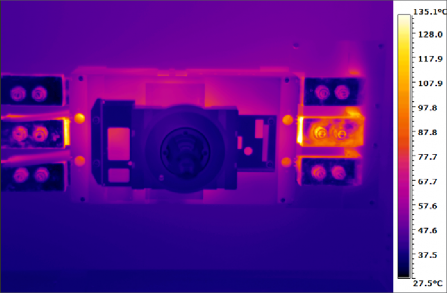

The MCCB seven days before the explosion and switchboard fire showing the discoloured

and scorched middle white phase busbar on the RHS of the MCCB

CASE IN POINT

As we could not determine the cause of the

abnormal heating our recommendation to

the maintenance manager was to connect

a waveform analyser and power monitoring

equipment. This was to ascertain if harmonic

distortion was affecting the operation of

the MCCB and to monitor the load over

an extended period to document any load

variations and if there were any load spikes.

The MCCB was replaced after our

report had been issued and a follow-up

survey was conducted to confirm that the

abnormal heating issues had been rectified.

The follow-up survey confirmed that the

abnormal heating issue had been resolved

with the replacement of the MCCB. At the

next annual survey and other subsequent

surveys, we could see that the displayed

thermal patterns on the MCCB were

again becoming more abnormal. This was

associated with an apparent temperature

rise internally in the MCCB and around the

centre white phase connections.

The exception and Delta-T readings

were not evaluated as a Priority 1 however

the evidence was conclusive that the

exception was becoming worse. After

each thermography survey the abnormal

heating was noted and reported to the

Maintenance Manager.

When this last survey was

conducted it was approximately

2 years after the original MCCB had been

replaced. The abnormal thermal patterns & apparent temperature rise on the MCCB

had been reported after each survey so I was

alarmed when we opened the panel and felt

the extreme heat emanating from inside the

MCCB cabinet.

The thermal patterns around the centre

white phase were indicating an anomaly

which was originating from inside the

MCCB. The apparent temperature of the

exception had risen from the previous

survey by approximately 30°C. There was

also visible discolouring & scorching on

the RH copper busbar connected to the

MCCB. Given the history, this was now a

Priority 1 fault and needed immediate action

for rectification.

The maintenance manager was informed

of the P1 thermal anomaly immediately

and we did emphasise the importance of

a rapid response by his maintenance team.

The thermography inspection report was

compiled the same night and emailed to the

maintenance manager. A subsequent email

was sent to confirm that he had received the

report, again emphasising the criticality of

the fault.

Depending on the type of exception,

it is impossible to predict a failure based

on temperature. However, training and

experience over many years of conducting

thermography inspections and looking at

thermal anomalies, alerted us to the fact

that we had identified a very serious issue

in the MCCB.

Thermogram of the MCCB before it exploded and caused a fire. Apparent temperature

on the RH white phase

near the body of the MCCB was 147°C. Apparent temperature on

the LH white phase near the MCCB body was 136°C

RESULT OF INACTION

Appropriate action was not taken

immediately and 6 days after the report

was submitted the MCCB exploded,

destroyed the switchboard, and the plant

was shut down.

Rectification cost and production losses

were substantial and the ramifications

of such a preventable failure were also

measured in job losses at the plant.

The switchboard was destroyed by the explosion and fire

IN SUMMARY

- Thermography is a proven predictive/preventive maintenance tool and when

utilised by trained technicians can

identify thermal faults early, well before

equipment failure.

- Not paying attention and not acting

on the results of a thermography

survey in an appropriate time frame

can be catastrophic and cost many

thousands of dollars. In this case early

investigations into the root cause of the

abnormal heating may have prevented

this failure.

- While thermography effectively identifies thermal faults, it is impossible to predict the actual timing of failures based on temperature only.

- A detailed and comprehensive thermography inspection report that identifies thermal faults for clients is vitally important for the safe and reliable operation of electrical assets and cannot be underestimated.

Advertisement