|

Craig Nelson, CESW, CESCPJM Test Systems, Inc. Ph: 225-925-2029 x3122 |

The NFPA 70E® Standard for Electrical Safety in the Workplace is reviewed and revised every 3 years in response to input from a wide variety of sources including the general public.  These are carefully reviewed and, if found to have merit, adopted. The standing committee also implements many changes on their own after intense discussion and careful consideration. As there always are, several changes took place in the 2021 edition. Many of them are “housekeeping” items such as section reference numbers that change due to adding and moving things within the document, updating references and an ongoing effort to harmonize this standard with the National Electrical Code. As in the past, a lot of work has gone into adding informational notes. A few very significant changes and additions were made that we need to be aware of because they impact the way we apply the standard. There is major reorganization in Article 110, a completely new Informational Annex R, additions to Chapter 3, and a few seemingly minor additions that impact the application of PPE, and arc flash risk assessment.

These are carefully reviewed and, if found to have merit, adopted. The standing committee also implements many changes on their own after intense discussion and careful consideration. As there always are, several changes took place in the 2021 edition. Many of them are “housekeeping” items such as section reference numbers that change due to adding and moving things within the document, updating references and an ongoing effort to harmonize this standard with the National Electrical Code. As in the past, a lot of work has gone into adding informational notes. A few very significant changes and additions were made that we need to be aware of because they impact the way we apply the standard. There is major reorganization in Article 110, a completely new Informational Annex R, additions to Chapter 3, and a few seemingly minor additions that impact the application of PPE, and arc flash risk assessment.

One of the major changes is in Article 110. The committee felt that general requirements scattered among Articles 105, 120 and 130 should be gathered into article 110, and assembled and organized into a logical sequence of general requirements for electrical safety-related work requirements, the title of Article 110. This will affect the administrative side of a safety program and safety training, and may impact some procedures as these items are moved out of the procedures and into the overall requirements of the program. Workers generally don’t care about these “structural” changes, but nevertheless, they are still important and must be addressed. They may change the procedures workers are required to comply with and, therefore, may require some retraining to cover them.

As a reminder, for those performing thermographic work, the standard still provides for performing this work without an energized electrical work permit when there are exposed, energized electrical circuits and parts such as when the door of a motor starter is opened. The restriction is that the restricted approach boundary must not be crossed. If the limited approach boundary is crossed, the thermographer must be a qualified electrical worker. If they aren’t, they must be escorted at all times by a qualified electrical worker. If the arc flash boundary is crossed, then arc flash protection must be implemented.

One significant change involves arc flash personal protective equipment (PPE). In the past, PPE requirements listed outerwear such as parkas and rainwear in the various categories such that they had to be at least equal to the calorie rating of the other arc flash clothing. The standard now states in a footnote that “The arc rating of outer layers worn over arc-rated clothing as protection from the elements or for other safety purposes, and that are not used as part of a layered system, shall not be required to be equal to or greater than the estimated incident energy exposure.” This change in the standard significantly eases the problem of finding arc-rated outwear in the higher Arc Thermal Protection Values (ATPV). The reasoning is that if the primary arc flash PPE is the correct value, should there be an arc flash event and arc-rated outerwear of a lower value fails, the worker is still sufficiently protected by the arc rated clothing underneath as long as it is of the required ATPV value.

There are a few other tidbits on PPE. High-visibility apparel has been added to outerwear. Footwear that is not leather or dielectric is now permitted provided it meets the same requirements as arc rated clothing which is no ignition, melting or dripping when exposed to an arc flash. The definition of balaclava eliminated referring to them as head socks, and redefines them as head protective fabric that protects the neck and head except for the facial area. Incidentally, although it isn’t stated in the standard, it is also highly recommended that a balaclava be worn with all levels of arc flash PPE, and inside hoods as a second layer of protection for the head. The standard also now states that the use of PPE other than or in addition to that listed in the tables and elsewhere in the standard shall be permitted provided it meets the requirements specified in the standard.

Many people are unaware that rubber insulating gloves also provide arc flash protection. It was never mentioned in 70E until now. While no specific thermal values are given, manufacturers have tested them and their arc resistance is known. Leather protectors also provide arc flash protection. Not all manufacturers provide arc ratings for protectors, but some do and have tested them according to ASTM F2675/F2675M-13. Ratings are not provided for either one in 70E, but the standard does state that, “Rubber insulating gloves with leather protectors provide arc flash protection in addition to shock protection. Higher class rubber insulating gloves with leather protectors, due to their increased material thickness, provide increased arc flash protection requirement.” This is a step in the right direction, but we hope that in the future, all electrical insulating gloves and protectors will include arc thermal performance values. As a side note, if electrical work isn’t being performed and electrical PPE is not required but arc flash protection is, arc-rated gloves are also available that include a variety of other characteristics.

Many people are unaware that rubber insulating gloves also provide arc flash protection. It was never mentioned in 70E until now. While no specific thermal values are given, manufacturers have tested them and their arc resistance is known. Leather protectors also provide arc flash protection. Not all manufacturers provide arc ratings for protectors, but some do and have tested them according to ASTM F2675/F2675M-13. Ratings are not provided for either one in 70E, but the standard does state that, “Rubber insulating gloves with leather protectors provide arc flash protection in addition to shock protection. Higher class rubber insulating gloves with leather protectors, due to their increased material thickness, provide increased arc flash protection requirement.” This is a step in the right direction, but we hope that in the future, all electrical insulating gloves and protectors will include arc thermal performance values. As a side note, if electrical work isn’t being performed and electrical PPE is not required but arc flash protection is, arc-rated gloves are also available that include a variety of other characteristics.

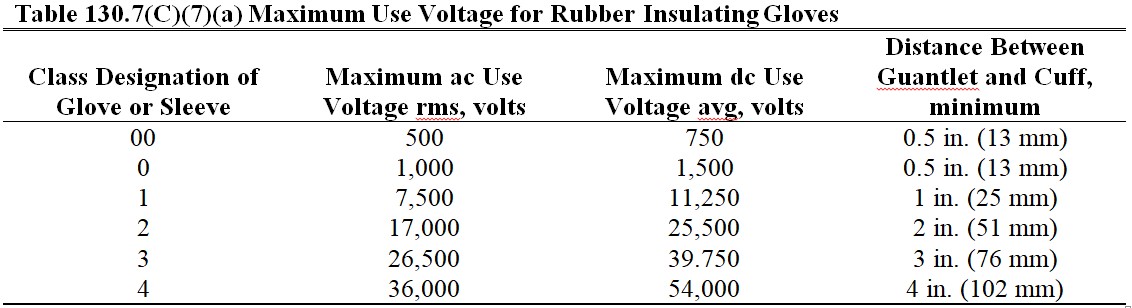

Another significant addition for 2021 is Table 130.7(C)(7)(a) Maximum Use Voltage for Rubber Insulating Gloves. In the past, we relied on manufacturers’ literature for this table which lists the class of glove, and maximum AC and DC voltage ratings. This table also includes the minimum distance between gauntlet of the leather protector and cuff of the rubber glove. This distance is very important to maintain enough clearance between the end of the leather protector gauntlet which is non-insulative and the user’s arm which is protected by the length of the cuff of the rubber glove.

Copyright NFPA 70E® 2021

While the requirements for testing and retesting rubber insulating equipment did not change, a subsection was added under Hand and Arm Protection that stipulates that this equipment shall be subjected to periodic electrical tests, that those tests shall comply with applicable standards, and that maximum intervals between tests shall not be exceeded.

There are numerous examples over the years of circuit breakers and switches failing when racked in or operated after they have been serviced, or during commissioning when initially operated under load. I n Table 130.5(C) Estimate of the Likelihood of Occurrence of an Arc Flash Incident for AC and DC Systems, the following task has been added: “Operation of a CB or switch the first time after installation or completion of maintenance in the equipment.” Along with the other tasks in this group, are considered to be a likelihood of the occurrence of an arc flash incident in any condition. It is really important to pay attention to this one because all too often people have assumed equipment under these circumstances is not likely to fail.

The requirement of performing a risk assessment prior to any work on a battery system is not new for 2021, but what has been added is Section F.7 in Informative Annex F. It emphasizes the multiple hazards that may be involved when working on batteries and may include some or all conditions consisting of arc flash, shock, chemical and thermal. This section provides an example of a qualitative two-by-two risk assessment matrix and an excellent, extensive hazard assessment flow chart. Also added in Article 320 concerning battery safety is a new section covering tools and equipment that includes insulated handles on tools, the use of non-sparking tools, and keeping tools and equipment clear of unintended contact with battery terminals.

The greatest hazard with capacitors is their ability to store and retain high levels of energy long after the power source has been removed. Following that is the assumption that they have been properly discharged or that monitoring devices correctly indicate that they are. An entirely new Article 360 has been added to cover safety requirements for capacitors. Even small capacitors can pack quite a wallop, but capacitors used in variable frequency drives for large motors, and utility substations and distribution systems are absolutely lethal. Key elements of this article are qualifications and training, performing a risk assessment, establishing a safe work condition and safe work practices. To supplement this article is Informative Annex R, Working with Capacitors. This annex provides an abundance of information on things such as duration of discharge (very important), proper discharge and grounding along with a flowchart for testing and grounding methods to establish a safe discharge.

For those who make arc flash calculations, a very important change was made in Informative Annex D, Incident Energy and Arc Flash Boundary Calculation Methods. Contained in Annex D isIEEE 1584-2018, Guide for Performing Arc Flash Calculations. As you may know, far reaching changes were made in this standard as a result of advances in arc flash testing methods and studies that have been performed. As a result, Section D.4, IEEE 1584-2018 Calculation Method, has been completely rewritten to provide an overview of the significant changes in the 2018 edition of IEEE 1584. Several pages of equations were eliminated. The committee felt that the content would be better served to refer to 1584 itself.

NFPA 70E is reviewed continually and the process of considering revisions begins not long after the current edition is released. Changes are made judiciously and prudently, but there are always changes nonetheless. As noted, an updated edition is published every 3 years and released in September of the revision year (i.e., the 2021 edition was made available September 3, 2020). Electronic versions are no longer available beginning with the 2021 edition. Although more expensive, the handbook is a very valuable investment. There is an abundance of additional information, examples of applications of the standard and interpretations of its content.

It is important to stay current with changes to NFPA 70E because OSHA recognized it as the consensus standard for electrical safety. OSHA regulations generally coincide with 70E, but there are often differences in wording and details. NFPA 70E is a standard, and therefore, a technical reference, but it can be a regulatory document if the AHJ (Authority Having Jurisdiction) designates it as such. Be sure to check on that. OSHA regulations are federal law and legally enforceable, and are what we must comply with where OSHA has jurisdiction. For this reason, it is very important to stay current with OSHA regulations as well.