Ed Kochanek

Director of Regional Sales

FLIR Commercial Systems Inc.

25 Esquire RoadNorth Billerica, MA 01862Ph: 866-379-4022www.flir.com/thermography/americas/us/

Abstract

New remote thermal imaging solutions are gaining considerable attention among industrial end-users. We will showcase applications that improve safety monitoring, process control, quality assurance, and security which are helping companies prevent expensive equipment failures, hazards, production losses, and intrusions. Learn how FLIR Automation thermal cameras keep an infrared eye on substations, critical vessels, production lines, and parts inspections. Also discover the promise of new Wi-Fi technologies that are making it possible to remotely control and stream images from portable handheld IR cameras for safe viewing of potentially dangerous targets.

Introduction

In the last couple of years we have all witnessed the great advances in the hand held infrared camera market. Lower cost and amazing features have led to a wide acceptance of this technology to solve many problems that plague our everyday life at work and home.

The same can be said of fixed-mount infrared cameras. Prices have come down dramatically in the last couple of years making them an affordable solution to visual light cameras.

Another innovation has been the adoption of standard communication and video formats. Visual light cameras have been the mainstay of security and machine vision applications because of software solutions written for them. Now that infrared cameras have the same software capabilities, they can be easily used when a visual light camera is inadequate. These innovations allow OEMs and integrators a cost effective solution with many of today’s security & machine vision software platforms.

Discussion

Ether-Net/IP/ GigE Vision/GeniCam

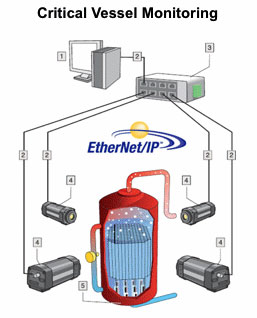

Fixed-mount infrared cameras can come with ModbusTCP and or Ether-Net/IP open communication protocol allowing them to integrate into a wide array of machine vision applications. Simply said, with this solution you can plug and play into your existing network.

GigE Vision provides a standard interfacing architecture for machine vision systems based on the gigabit Ethernet communication protocol. This allows you to seamlessly integrate hardware and software from a variety of third party vendors.

If you already have a machine vision system that is GeniCam compliant, cameras are drop in ready and will seamlessly integrate. GeniCam makes it easy to control camera settings, command and control and use the temperature measurement results directly into the image data stream.

Here are several applications that take advantage of these new infrared camera software solutions:

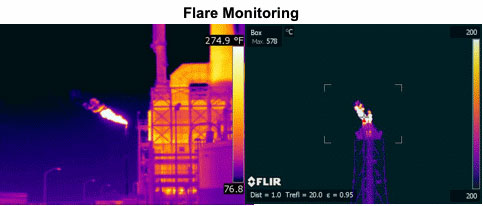

At chemical plants flares and pilots must burn off excess gas. Sometimes the flare goes out without anybody knowing it. An infrared camera can quickly tell if this happens. The cameras measure the flame as a hot spot. If the flame goes out the camera measures the cold sky. If this happens the camera alarms the plant via EtherNet/IP. This saves the plant from fines for exhausting VOC gases into the environment.

A metal tank is lined with an insulating material. In the past, customers used thermocouples to monitor temperature, but with poor results. Hot spots usually occurred where there was no thermocouple. Multiple cameras are networked together using Ethernet to measure the temperature of the entire circumference of the tank. If a hot spot is detected, an alarm is sent to the PLC indicating an issue.

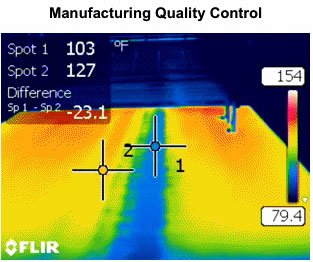

In this case, ceiling panels must be manufactured at a specific temperature. If the temperature is too low the glue doesn’t melt and adhere properly. The infrared camera monitors for this effect. When this happens, the camera sends an alarm to the PLC to stop the machine.

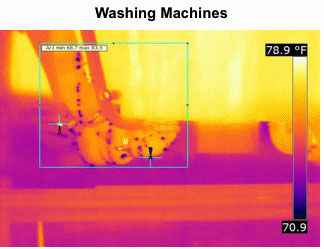

Not everything needs to be hot. In the case of a washing machine the last thing a customer wants is one that leaks. Water is difficult to see by a visual camera. However an infrared camera detects water leaks easily as water cools when it evaporates. The infrared camera monitors for low temperature and sends a temperature value to the PLC which quarantines that part.

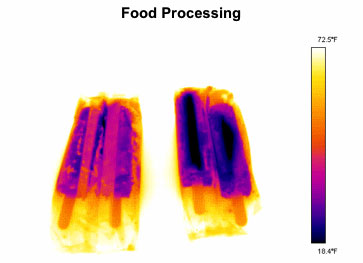

In food processing, consistency is very important. It conveys trust that the product was manufactured correctly. With popsicles, children only care if it tastes good. The parent on the other hand would question the quality if the product looked odd.

In this case the popsicle is wrapped in a white plastic covering which is opaque. A visual camera could not inspect them to see if it was manufactured to the correct specifications. Since long wave infrared cameras can see through some thin film plastics, the infrared camera is the perfect solution. Using GIGE vision and GeniCam the machine vision software provides the analytics to detect if there are two popsicles in each bag and if they are oriented correctly.

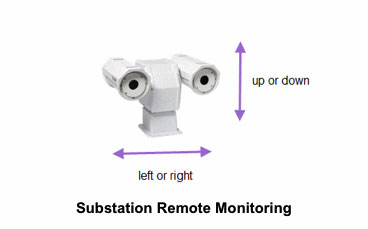

Up until now we have looked at targets that are in a predictable location. When the area is larger than the camera can view we add a pan and tilt module. This way the camera can scan a larger area without adding additional systems.

North American Electric Reliability Corporation (NERC) standards have brought about significant challenges for electric utility operators in order to comply with Critical Infrastructure Protection (CIP) programs. NERC Standards CIP-002-3 through CIP- 009-3 outlines a cyber security framework for the identification and protection of Critical Cyber Assets to support reliable operation of the Bulk Electric System. What does this mean for the utility company that provides power to commercial and residential customers? It now means that they must have a strategy and plan in place for such an attack.

Take for example an electrical substation. There must be a plan in place for these critical assets that is able to maintain a level of physical security to ensure that the system operates uninterrupted. How are utilities doing this today? There are a host of different technologies from fence line monitoring systems to permanently installed security cameras. These security cameras provide a level of security for a very affordable price. In daylight, they can detect, recognize, and alarm on mischievous behaviors. But what happens when the sun goes down or the weather degrades the camera’s ability to detect objects? Infrared cameras are an ideal solution to any critical infrastructure program. They can detect heat, so light is no longer a problem. What about fog? Infrared can “see” through most conditions of fog. Better yet, these permanent security systems can provide the first level of imminent danger, when a transformer or circuit breaker has a high temperature differential across connections.

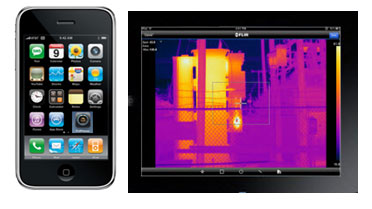

What if a situation presents itself that compromises the safety of the thermographer? How do we get an infrared picture safely? Well, today’s hand held infrared cameras offer remote vision capabilities as well. Infrared camera manufacturers are installing WIFI transmitters in cameras, giving them the capability to send images from the camera directly to a smart phone or tablet computer.

This way, a customer can mount a camera in a hazardous area while operating it from a safe distance. Some cameras can send snapshots to the smart phone while others can send video.

The users of the remote software have full functionality of the image or video as if they are holding the camera themselves. They can focus the camera, adjust the image and use measurement tools to measure any target the camera is looking at.

It’s also a valuable tool when other colleagues need to see the same image.

Conclusion

In conclusion, infrared cameras for remote and machine vision applications are quickly becoming a viable alternative both technically and economically. As this happens new applications will become economically feasible for infrared cameras. Who knows when the next application will show up? But remember, if you can’t see it with your own eyes that doesn’t mean it’s not there. An infrared camera may be the solution.