Electricity Conservation Technology– A Revolutionary Way to Save Electricity, Money and Reduce Pollution

Paul Grover, President

Kilawatt™ Partners

44 Juniper Ridge

Shelburne, VT 05482

802-985-2285

Abstract

For years energy conservation has meant sitting in a cold dark room. Now it means being smart by using only what you need. Once you learn how to use electricity wisely, you can take control of your electricity use and eliminate costly waste.

The Energy Problem

Energy is perhaps the most important challenge facing the U.S. in the coming decades. Domestic gas and oil production have been declining since the 1970’s. No new nuclear plants have been built in many years. The only plentiful fossil fuel remaining in the U.S. is coal, with its attendant environmental problems. The U.S. is increasingly dependent on foreign oil, a policy with tremendous negative long-term consequences. Moreover, it appears that portions of our electricity infrastructure cannot accommodate growing demand. Since the early 1980’s, the U.S. has attempted to curtail energy only through efficiency programs.

The Efficiency “Solution”

One of our country’s policies has been to invest in energy efficient equipment. Engineers originally created the term “efficiency” to quantify machinery performance. Efficiency is “the ratio of (useable) energy developed by a machine to the energy supplied to it, usually described as a percentage.” If we put 100 units of electricity into a motor and get back 60 units of motor energy to use, that motor has an efficiency of 60%. Efficiency is the technological approach to energy reduction. The problem is that these efficiency programs, often termed “demand side management,” have not decreased energy use and, in most cases, have increased use.

Energy efficiency may have enabled consumers to get more benefits from the electricity they use, but resource use continues to increase. For example, our cars are increasingly fuel efficient yet we drive more miles per vehicle, using more gas every year. It’s like buying low-fat potato chips to “save” calories and then eating the whole bag. Solely practicing energy efficiency is not good for our environment, our climate, our health and our increasing dependence on foreign energy resources.

The Conservation Solution

Energy conservation is quite different from energy efficiency. The late Vermont icon Fred Tuttle best summed up “conservation” when he told me, “If y’don’t need it, turn the durn thing off.” The goal of conservation is to minimize resource use and eliminate waste. While efficiency gets us more energy “bang for the buck” when equipment is on, conservation gives us even greater benefit when that same equipment is off. When it comes to saving money and reducing the demand for resources, nothing beats off.

This simple example illustrates the difference:

-

After we turn on a light, our concern is efficiency, or how to get a high ratio of light for the electricity used.

-

When we turn that light off, we are practicing conservation. We preserve resources (like fossil fuels) that do not need to be burned to generate electricity to light the bulb, whether the bulb is energy efficient or not.

If energy efficiency is our only concern and we do not practice conservation, lights burn night and day whether we need them on or not. But as long as the bulbs are energy efficient, we are using electricity efficiently (getting back a high percentage of the energy we put in). There are no limits to efficiency: the longer we burn our energy efficient bulbs, the more we “save.” Efficiency without conservation obviously wastes a lot of electricity.

Why Electricity and Not Fuel Conservation?

Kilawatt Partners initially chose to address electricity use, instead of fuel use, for several reasons:

-

Though the methods for billing are complex, electricity can be measured relatively easily and accurately.

-

While electricity is the most convenient way to deliver energy, it’s also the most wasteful. Roughly 2/3 of the electricity generated is lost by the time it gets to the end user. This energy is lost as waste heat.

-

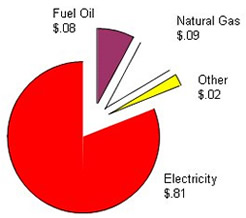

In New England, for example, $0.81 of every energy dollar spent in a commercial building goes to pay for electricity. This percentage typically increases as we move further south due to increasing air conditioning load. Therefore, if we’re concerned about reducing energy bills in commercial buildings, our primary focus should be electricity.

|

|

Table #1: Energy Costs for Commercial Buildings in New England

Source: Energy Information Agency |

Kilawatt Partners uses electricity conservation technology to produce electricity savings of 32-43% in commercial buildings in Vermont. These are not projected or estimated savings, they are real kWh reductions calculated by comparing monthly utility bills to baseline bills. In other words, we’ve proven that commercial buildings waste 32-43% of the electricity they pay for.

Client Benefits

By practicing conservation, Kilawatt clients benefit in at least four ways:

- Slashing electricity use saves money. The longest return-on-investment of any of our clients has been 3 months. In some cases, the R.O.I. is zero months. We are now working with a local school that will actually make money by reducing electricity use and still yield us a good profit.

- When our clients demand less electricity, fossil power plants need to burn less fuel, meaning fewer pounds of CO2 and other pollutants are dumped into the air we breathe.

- When electricity use is controlled, the comfort of building occupants increases.

- Reducing electricity use and attendant pollution is a great public relations story. For example, schools desperately need to reduce operating expenses and be able to share their success story with the community. Kilawatt Partners provides the savings and the graphs they need to tell their story.

How Kilawatt Achieves These Results

The Kilawatt service takes a different approach to reducing and managing electricity use. Here are some of the elements of our energy conservation technology. We:

- Focus on conservation, not efficiency

- Use specialized diagnostic technologies to gather data and verify system performance

- Customize action plans to meet each facilities’ unique needs

- Research how to conserve electricity in different systems

- Educate our clients

- Develop specialized software to analyze and track data and report results

We’ve also discovered “myths” that many people believe are true. For example, many people believe they should not turn off lights if they’re gone for only a short time because it takes a lot of electricity when they turn them on again. This practice actually made sense in the late 1940’s, but doesn’t today. Another myth is that computers should be left on all night because it is harmful to turn them off. There are instances where some need to be left on, but those conditions can be addressed individually. These myths are debunked when we provide proper analysis of our clients’ systems, understand their needs and provide supporting diagnostics and research to support our recommendations.

Finally, we use this hierarchy to reduce appliance electricity use:

- Turn it off

- Optimize its performance

- Replace it

Virtually all energy-reduction programs focus only on #3: they sell you costly energy-efficient equipment with typical payback periods of 2-7 years. The Kilawatt service focuses on #1 and #2, both of which provide quick returns with very little out-of-pocket investment. Simply put, we use our brains instead of our wallets.

Client / Personnel Requirements

Not every business is a good candidate for the Kilawatt Service. We typically charge a portion of the savings we produce over a period of time. This model requires establishing a baseline use against which current monthly utility bills are measured. Therefore, a client’s electricity use should be fairly stable for the past 2-3 years, and they should not be anticipating great changes that would affect electricity use during the Term of the Agreement.

Project Managers should have an in-depth understanding of conservation principles, the operation and analysis of the diagnostic equipment and of electrical and mechanical systems. They must be very skilled in working with people and organizations.

Technicians must be familiar with electrical and mechanical systems and be able to carry out the diagnostic tests and corrective actions specified by the Project Manager. They must be able to use equipment such as clamp-on ammeters, watt meters, temperature, humidity and CO2 data loggers, light meters, infrared point and imaging radiometers and the like. They must know how to read electricity meters and how different utilities charge for electricity.

Case Study 1: Network Performance, Inc.

Network Performance, Inc. was our second commercial client. It’s a small computer consulting business in South Burlington, VT. They did not pay us: we traded our services for research analyzing the electricity consumption of computers and peripherals.

One of the questions we needed to answer was whether Kilawatt savings were temporary or whether they would decline with time. Though our initial agreement with Network Performance was for one year, we have tracked their use for two. The only service we provided in the second year was sending them graphs of their use every other month.

As you can see from chart #1 at the end of this paper, Network Performance reduced their electricity use by an average of 32% over two years. Since the first year reduction was also 32%, their savings were the same for both years. They spent about $200 for materials to achieve these savings.

Case Study 2: Gregory Supply

Gregory Supply is a relatively small contractor/retail lumber store in Burlington, VT with an electricity bill of $33,000/year. Our contract was for one year and we shared the savings, with 80% going to Kilawatt and 20% going to Gregory Supply. Kilawatt paid the cost of all improvements to achieve a 20% reduction in kWh use. After that, the client was responsible for the costs of any recommended changes.

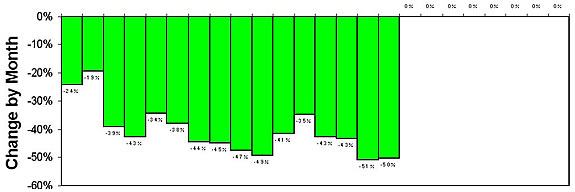

As you can see from chart #2 at the end of this paper, CO2 emissions (and kWh use) dropped by an average of 38% in one year. We are continuing to track their use and, after 15 months, the average reduction is up to 40%. Kilawatt’s material costs were less than $400 and Gregory Supply invested about $4,500 in the project, which they recovered in about 3 months.

Case Study 3: Jager Di Paulo Kemp Design

Also located in Burlington, Vermont, JDK is a design company located in a large renovated 3-story brick building dating to the late 1800’s. They had an electricity bill of about $50,000/year and 80 employees. In this arrangement, JDK paid Kilawatt 10% of their previous year’s electricity bill up-front and all the savings for one year.

As Chart #3 shows, emissions (and kWh use) are down 43% to date. Kilawatt’s equipment expenditures to date have been about $400. JDK has invested no capital in the project. They will recoup their up-front investment in about 2 months.

Summary

Electricity conservation technology embodies new paradigms, principles and inexpensive diagnostics to produce sizeable electricity cost savings in commercial facilities. When delivered by qualified providers, the Kilawatt service provides clients with payback periods previously thought impossible. Reducing electricity use also benefits the environment since fossil power plants need to burn less fuel, thereby reducing greenhouse gas emissions. Electricity conservation technology and the Kilawatt system provide a profitable opportunity for service providers.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advertisement