Infrared Thermography to Detect Refractory Damage in a Fluid Catalytic Cracking Unit

Robert K. Weigle

Infraspection Institute, Certified Infrared Thermographer 6175

Jersey Infrared Consultants

PO Box 39, Burlington, NJ 08016

Tel: 609-386-1281 /Fax: 609-387-4334

Abstract

Refractory materials comprise a key component in the insulating system of large boilers and petrochemical processing units. While refractory lining provides thermal insulation for many units, for some it provides critical wear protection from abrasive compounds.

Because missing or damaged refractory will cause a change in the surface temperature of an operating refractory lined vessel, thermography can be used to detect and monitor problem areas. This paper documents the infrared inspection of a petrochemical refinery’s Fluid Catalytic Cracking Unit over a six month period showing the development and monitoring of refractory breakdown following an upset, the visual correlation of internal damage during a scheduled shutdown, and quality assurance testing after restart of the subject unit.

Introduction

Thermography has a variety of uses in petrochemical refineries. Some of these uses include: inspecting electrical distribution systems, testing of steam and product lines, verifying heat trace lines, checking for coke deposits in process heater tubes, determining sludge and product levels in storage tanks, and detecting refractory damage in processing equipment.

The Fluid Catalyst Cracking Unit or “Cat” unit is a refractory lined hydrocarbon refining unit that utilizes a catalyst to convert or crack heavy, low-value portions of crude oil into heating oil, diesel and gasoline. The Cat Unit is referred to as “fluid” because the catalyst flows back and forth between the two major vessels of the Unit which are the Reactor and the Regenerator.

This catalyst is a fine powder with an average particle size of 60 microns. When catalyst is mixed with vapor it will “fluidize”, i.e. take on properties of a liquid. This allows the catalyst to continuously circulate through the Cat Unit; in certain places the catalyst moves at a velocity of over 100 feet per second (68 mph). The circulation rate between the Reactor and Regenerator vessels is approximately 100 tons of catalyst per minute. Catalyst temperature varies throughout the process but is typically between 800 °F and 1300 °F.

Because catalyst moving at high velocity is abrasive in nature it can physically erode bare metal. Depending upon metal thickness, moving catalyst in contact with unprotected steel can wear through the steel in a matter of hours. This is one of the reasons that refractory is such an important component of a Cat Unit. Refractory is an insulating material similar in texture to lightweight concrete. Installed inside the Cat Unit next to the outer shell, it provides a physical barrier to prevent abrasion. In addition to protecting the shell from abrasion, the refractory also provides vital thermal protection as well. Ideally, a properly installed refractory lining will keep exterior surface temperatures of an operating Cat Unit below 400 °F.

The extreme conditions inherent to the oil refining process take their toll on refractory, and for this reason, refractory has a typical life span of approximately five years in an FCC unit. Loss of refractory in a vessel causes thermal patterns to form on the shell. Thermography is one of the best ways to search for the patterns associated with missing or damaged refractory. These patterns, when monitored and compared over time, can provide an inspector with evidence of conditions he would be unable to obtain without thermography. Performed regularly, these infrared inspections will provide the data necessary to diagnose potential trouble areas before other indications would.

Site History

Located in Linden, NJ, on New York Harbor, our subject refinery is the northernmost refinery on the eastern seaboard and has the largest fluid catalytic cracking unit in the world. The refinery receives crude oil via tanker primarily from the North Sea and West Africa. The facility distributes its refined products to customers on the U.S. East Coast via pipeline. The product balance changes for seasonal consumer demand. Gasoline – mainly reformulated – is in high demand during the summer season, while in winter, the refinery optimizes operations to increase heating oil production.

Major refined products include gasoline, low-sulfur diesel, home heating oil, jet fuel, and propane. The refinery is capable of processing 250,000 barrels per day of crude oil.

Originally built in 1949, the Cat Unit is capable of processing 131,000 barrels per day of gasoline and comprises a critical part of the refinery’s production capabilities. With the exception of regularly scheduled, full maintenance shutdowns or “turnarounds”, the Cat Unit operates 24 hours per day throughout the year. Turnarounds are normally performed once every five years. Because a large portion of the refinery’s output capacity is directly related to the operation of the Cat Unit, it is critical that the Cat Unit remain in full operation between turnarounds.

Jersey Infrared Consultants have been routinely performing infrared inspections on this site since 1991. During this time we have performed infrared inspections on numerous processing units, pressure vessels, process heaters and the FCC Unit. All infrared inspections are performed by experienced, Certified Infrared Thermographers in accordance with currently published standards and currently accepted industry practices. When standard techniques were not available, we worked with site engineers to develop inspection procedures to meet project needs. Whenever possible, infrared readings are cross-verified through independent means such as contact temperature measurement and visual inspections.

Originally, infrared inspections of the Cat Unit were performed annually; however, as thermography became an integral part of condition monitoring, inspection frequency was changed to quarterly. In addition to these quarterly inspections, we have performed emergency inspections, usually associated with process upsets.

Thermography for Condition Monitoring

Approximately every three months we perform an infrared inspection of the Cat Unit for condition monitoring. Due to the large physical size of the Unit, the collection of infrared data takes approximately 40 hours to complete. During the infrared inspection, we inspect all non-insulated surfaces of the Cat Unit where line-of-sight access is possible. We record all thermal data to videotape and hardcopy thermal images for baseline purposes and to monitor known hot spots. The total discrete areas recorded for the Cat Unit typically number over 400.

In May 2002, we began what was to be the last infrared inspection prior to a regularly scheduled shutdown. With this turnaround scheduled to begin within the next few months, we paid particular attention to finding new hot spots. Since the Cat Unit vessels had been running for close to five years since the last full turnaround, it came as no surprise that there were several new areas. The inspection was concluded without incident, and we generated our normal report.

Several weeks after the May 2002 infrared inspection was completed, an upset occurred on the Cat Unit. One of the Unit operators thought he heard thunder; however, the rumbling continued for far too long. He called the Console Operator and together they investigated the Cat Unit in an attempt to locate the source of the noise. Initially, the source of the noise was found to be on the 4th level deck; eventually it was narrowed down to the Regenerator Cone.

Visual inspection of the Regenerator Cone revealed that the heat reactive paint had discolored. Heat reactive paint is used by refineries to locate hotspots on vessels. When it is exposed to a predetermined temperature, it is engineered to change color. It is a one-time change, and never reverts to back its original color. However, as it is exposed to the elements constantly and usually is not repainted for years on end, sometimes it is not reliable.

In addition to the paint, the operators of the unit had noticed an intermittent rhythmic clanking in the area of the Regenerator Cone. According to one operator, “It sounded like a Volkswagen was tumbling around in the Regenerator.” As a precaution, product feed rates were lowered temporarily until more information was gathered.

The inspection department requested we perform an infrared inspection in order to confirm suspected conditions. For years, there were known hotspots on the Regenerator Cone. During our inspection we found that previously documented hotspots had greatly expanded. Where before there were only isolated hot spots, there were now signs of widespread refractory failure. It appeared as though large chunks were now missing throughout the circumference of the Regenerator Cone.

We left a copy of our field notes on site and generated our formal report. This aided plant managers in determining actions to take concerning the upset. Some of these decisions were whether to shut the unit down incurring a substantial financial loss, or to keep the Cat Unit online and risk the potential for catastrophic failure.

Discussion

A regularly scheduled shutdown was already planned to take place several months after the upset. It was the hope of the refinery management to keep the plant online until then. Regularly performed thermographic inspections were able to give some measure of assurance that the vessel would not be suffering permanent or catastrophic damage while waiting for the shutdown.

By verifying the actual size and shape of damaged areas, the exterior surface of affected areas could be cooled with steam lances. Three steam rings were fabricated and put in place in order to achieve the needed coverage. These steam lances helped to control the temperature of the Cat Unit’s steel shell, keeping it from reaching damaging temperatures. The steam was also utilized in an effort to control additional refractory loss due to thermal expansion. In addition to using the steam lances, refinery management decided to keep the feed rates reduced.

During the next several weeks until the shutdown began, we performed regular condition monitoring of the Cat Unit. The purpose of this monitoring was twofold: to ensure that the steam bath adequately covered the damaged area, and to make sure that the area of suspected refractory damage was not expanding. Eventually the feed rates were increased to an almost normal level. This would not have been possible without the data provided by the thermographic inspections.

Verifying Infrared Data

As the time of the shutdown approached, the affected areas were mapped out. With the use of thermography, the approximate size, shape, and location of the damaged areas were known before the unit was opened for visual inspection or shutdown. This resulted in better preparation of both materials and manpower and allowed for a faster and more efficient turnaround.

During the turnaround photos were taken of the damaged areas on the inside of the cone. These pictures almost perfectly matched our thermograms, some of which were taken weeks before the shutdown.

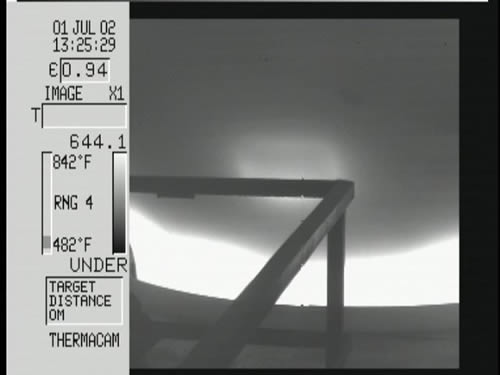

Refractory damage within Regenerator Cone |

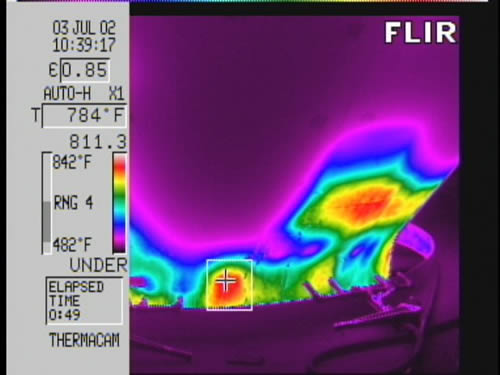

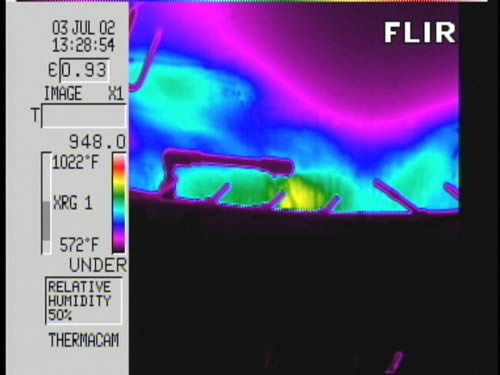

Hotspot caused by refractory damage within Regenerator Cone |

Refractory damage within Regenerator Cone |

Hotspot caused by refractory damage within Regenerator Cone |

Refractory damage within Regenerator Cone |

Hotspot caused by refractory damage within Regenerator Cone |

The source of the loud clanking was found to be a deflector plate which had broken away from its steel supports within the Regenerator Cone. This deflector plate, which weighs approximately two tons, had been banging into the sidewall of the Regenerator and had caused extensive damage to the refractory lining. The deflector plate eventually settled into place in the cone.

|

|

|

Photos show detached deflector plate lying inside of Regenerator Cone |

|

Damaged deflector plate after removal. |

As with all businesses, refineries try to keep downtime to a minimum. Unnecessarily extended shutdowns must be avoided. Most materials that refineries use to complete turnarounds are custom fabricated and not available without months of advance notice. Costs can multiply greatly if materials needed at time of shutdown are not present.

|

New Regenerator section prior to installation |

|

New deflector plate prior to installation |

Conclusion

As shown by this example, the benefits of using thermography as part of the PPM program on refractory lined vessels are many fold. Throughout the running time between shutdowns, systematic, regular monitoring was able to ensure that the refractory was surviving with only the expected minimal degradation.

Once the upset had occurred, thermography was key in locating and monitoring the affected areas thus allowing the inspectors insight into what was happening concerning the refractory lining of the vessels. This was accomplished with the unit online at normal production levels instead of shutting down prematurely, when neither parts nor manpower were available to effect proper repairs.

Thermography is one of the most efficient ways to detect evidence of damaged refractory within active petrochemical vessels. Thermography is nondestructive and requires no interruption of production. This case study further reinforced the need for a regular thermographic inspection program to the management of the refinery. Critical to the long term monitoring that has been performed at this site are the thermographers that have been trained and certified to industry standards and understanding the construction and characteristics of the subject vessels.

Advertisement