Infrared and the Information Age

Scott Cawlfield, President

Logos Computer Solutions, Inc.

3801 14th Avenue West

Seattle, WA 98119

Ph: 206-217-0577/Fax: 206-217-0573

Abstract

New technology has created new ways of storing, presenting, and backing up your information. Automation is happening in almost every area of the infrared industry. Customer expectations are changing in this market and insurance companies are influencing what is acceptable for a “professional infrared inspection”. New standards such as NFPA 70E have created new headaches for thermographers as well as some new opportunities. Knowing what is happening in this information age and how to best take advantage of the opportunities it presents will be discussed in more detail during this presentation.

Discussion

Automation

The key goal is to do more infrared inspections which you get paid for, and spend less time generating reports which you normally don’t get paid for. When you collect your inspection data, use a computer in the field since you will have to enter it into a computer eventually. If you can do 90% of the report while in the field, most of your time can be paid for by the client.

Does it take more time to do the data entry in the field on a computer vs. on paper and then enter into a computer? That depends on the system you use. Some take more time, while other commercial programs are highly automated and take less time than writing it on paper and then entering it into a computer later. Data collection devices range from small PDA’s to tablet PC’s shown below.

Databases

Electronic information is wonderful, but like anything else, you can have too much of a good thing. A good organization system and work flow is critical to smooth business operations, and the best solution for all that electronic data is storing them in a database. A database can help you store and retrieve large amounts of data in a very short time.

It is also a good way to backup your data in one place and if you use a database, either home developed or commercial, you can keep years of historical inspection data for your customers so they keep coming back for your services.

Insurance companies are growing to expect their insureds to have an accountable infrared inspection program that lists what has been tested and what has not been tested.

Ten years ago, nearly all infrared reports were printed on color printers and mailed to the customer. Today, more and more reports are being printed to Adobe Acrobat PDF files and emailed to the client, burned to a CD, or published on a secure web site. This growing trend saves trees (keep it Green) as well as gives much quicker response times for delivering your work product, the “inspection report”. Some people will always want a printed report in a thick binder to stick on their shelves, but the trend is moving towards transferring data electronically.

Electronic distribution saves not only on the color printing but on the shipping costs and shipping time for those 100 page reports that hopefully reach your customer. If the report gets lost in the mail or it gets lost in the wrong department and you have to reprint and reship it, your invoice and payment can be delayed by an additional 3 to 5 weeks. For most companies, cash flow is king and invoices can be generated as soon as the information is available by email or on the web site, thus reducing your delay in getting paid for your work.

Company Internet Websites

The internet is the information highway and company websites are valuable as electronic brochures and contact information. Below is an example of a good company website.

Does this company look professional and well established? Yes! And the web site is good at explaining who they are, what they do, and most importantly, how to contact them for services. A website can enhance your company presence, reduce printed brochures, and improve your brand awareness.

For companies who use a database and upload customer reports onto their website, their customers can view their report data as soon as it is uploaded. Information can be distributed almost instantly and customers can view the inspection reports from the comfort of their office or from anywhere in the world. Companies who use database automation for their infrared inspections can service very large companies since this is what large corporate accounts are coming to expect – access to the infrared inspection reports on their 100 corporate sites from their office computer. Corporations also want to compare results from site to site, seeing which site is most efficient or which site has the most problems. Also, corporations would like to deal with one company to do their inspections and expect one standard report format for all the inspections.

Websites for Training and Information Exchange

Websites can be informative and educational. For example, you can share questions or information among users through online bulletin board sites as well as receive online infrared training.

Learning online from your office saves travel and expense, reduces time away from your family, and also is better for the environment. Information and learning are no longer restricted to a specific time and place but are customizable to your needs and schedule.

NFPA 70E Standard

Another growing concern in the infrared industry is the NFPA 70E standard (also known as the Standard for Electrical Safety in the Workplace) which is being adopted for electrical safety. It has been around since 1979 and is now in its 7th edition. With more infrared inspections being done, more accidents happening, and more insurance claims being filed, review and changes in safety requirements are inevitable. Anytime a live electrical panel is opened for inspection, there is a potential for serious injury. Arc flash is a fact in this industry and will not go away, so NFPA 70E is designed to make the electrical industry more safe. Unfortunately, proper PPE clothing makes it hard to use the camera very well or do your job efficiently. For example, the “Bee Hive” suit, as some people call it, is a sauna on a hot day. But if an accident happens, and you are injured, insurance companies will expect that you did your job in a professional manner and complied with the published standards and took the necessary precautions.

As much as some people complain about the NFPA 70E standard, it is for the safety of the thermographers, just like helmets are for the safety of the motorcycle rider. Also, you don’t have to look very far to see the potential positive benefits of this standard as well. Some of the opportunities include:

• Consulting or training on NFPA 70E standard

• Performing Arc Flash Studies for your clients as an additional service

• Recommending or selling IR windows which add to your safety as a thermographer and can bring in some additional money for you

By keeping up to date on changes in the IR industry through infrared or maintenance websites and/or by attending infrared conferences, you can capitalize on new opportunities. By talking to other thermographers and learning what they are doing successfully, you can avoid many of the standard pitfalls in the infrared industry. Also, networking never hurts in this industry since you might end up working with some of your fellow thermographers.

Automation Case Study: Thermotest Inc.

Below is a case study of a successful, growing, infrared company that has implemented many of these ideas.

They have a company website to tell prospective customers who they are, what they do, and how to contact them. They show sample reports on their website (shown below). Once they get the contract to do the inspection, they use InspecTrend® and tablet PC’s to collect the data, generate the report and post it to the secure website.

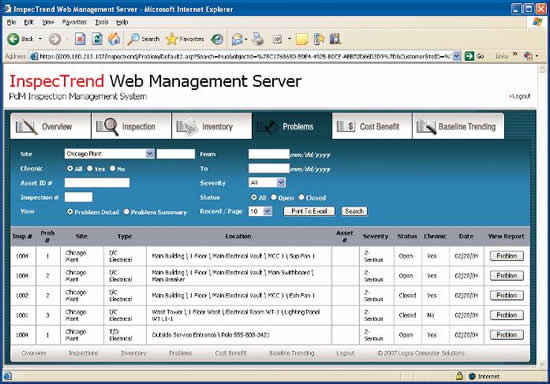

They use InspecTrend® Web Manager to share the reports and view summary and detailed reports.

This is their database web site that is accessible to their customers (demo data only – it does not have their logo on the top as it normally does).

The Results

How has this affected their business? Well, their manual inspection report generation, that used to take up to 2 weeks to process, now takes 1 to 3 days. Their staffing labor cost to produce the reports has been reduced by 1-1.5 man years. They have shortened their billing process, so now the customer receives the invoice soon after the job has been completed and the report has been posted online. They also have the ability to compete and win contracts for very large corporate clients who want to access their inspection reports online. All this automation has reduced costs and improved efficiency for their business so they can stay competitive and grow larger in the future. Thermotest also offers Arc Flash Studies for its customers and potential customers as an additional service.

If you would like to get more information on this automation case study, you can call or email Norman Eisenberg, president of Thermotest, who would be happy to answer additional questions on how he streamlined his infrared business. His Email is:

Summary

Many automation tools are available today that will allow you to be more productive in less time. How you use these tools and information is up to you. I wish you the best of success in this “Information Age”.

Acknowledgements

Thanks to Norman Eisenberg for his willingness to share his knowledge with others and to the Seffrins for their continued contributions to this industry.

Advertisement