Adrian Messer

Manager of US Operations

UE Systems, Inc.

Ph: 864-224-4517Cell: 914-282-3504 www.uesystems.comAbstract

Ultrasound and infrared technologies are a perfect match when conducting inspections of switchgear over 1000 volts. At this voltage class and higher, thermal anomalies as well as corona and tracking conditions can occur, all of which threaten the reliability of the equipment being inspected. Typical switchgear at this class includes, load interrupter switches, breakers, transformers, motor controls and terminal transition cabinets.

This presentation will present case studies that highlight over ten years of switchgear inspections performed by Jim Brady of Brady Infrared, including thermal images. Corona and tracking sound files will be integrated into this presentation to show their relationship to problems that occur in this type of electrical equipment and how the use of ultrasound and infrared technologies can be used together to easily identify potential failures in metal-clad switchgear before they become catastrophic.

Introduction

Electrical Equipment

Metal-clad switchgear can be defined as all live electrical parts are enclosed grounded metal compartments. Traditional inspection of metal-clad switchgear is performed by noncontact infrared cameras.

In recent years, ultrasound instruments have been added to these inspections for various reasons. Ultrasound instruments can be used to inspect energized electrical components on low, medium, and high voltage systems. Corona is easily detected with ultrasound, and may go undetected when using only an infrared camera.

Corona

Corona refers to the ionization of air surrounding an electrical connection. Corona, by nature does not produce significant heat to be detected by an infrared camera. If left undetected, and if corona should continue to occur, it can lead to more severe problems in metal-clad switchgear. By-products of corona include ozone, electromagnetic emissions, nitric acid, and ultraviolet light. More prominent signs of corona include a smell of ozone in the area of electrical gear, unusual weathering patterns on bus, an accumulation of white powder and dust on insulators, carbon tracks on insulators, and discoloration and deterioration of insulated conductors.

|

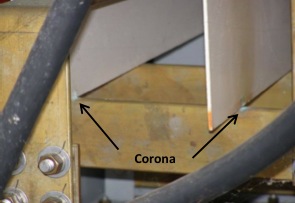

Figure 1: Corona activity advancing to the tracking stage on insulation board resting on 13kV bus. Notice the carbon deposits and light brown discoloration of the insulation board on the right. |

|

White powder & discoloration on cables |

Even though corona produces little to no heat, it does, however, produce ultrasonic emissions. If the inspector’s ultrasound instrument has on-board sound recording capability, the ultrasound emission from corona can be recorded and further analyzed for a correct diagnosis. A note of importance on corona is the fact that it is only present in voltage above 1000 volts. At 1000 volts and greater, air becomes a conductor and hence the ionization of air surrounding a connection can occur. If inspection is being done on voltages below 1000 volts, and an ultrasound is heard, the inspector can rule out corona as a possible diagnosis.

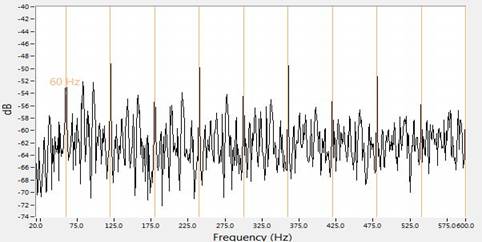

Recorded ultrasound of corona as seen in an FFT spectral view

When the recorded ultrasound of corona is looked at in a spectrum analysis software, very prominent 60Hz harmonics can be noted. If the sound recording is done outside of North America, one would see very dominant 50Hz harmonics. Additionally, in between the 60Hz harmonics, you would see what is referred to as frequency content. Frequency content is basically harmonic activity between the more dominant harmonics. As the condition worsens, there will be a loss of the dominant 60Hz harmonics, and uniformity in the amplitude of the recorded ultrasound will decrease.

Tracking

Tracking occurs when there is a low current pathway to ground across an insulator. Many will refer to tracking as “baby-arcing”. This event is common where there is severe breakdown of the insulating material and loose connections. Tracking can occur in low, mid, and high voltages and is characterized as a steady buzzing sound with periodic “crackling” and “popping” sounds. Further damage is done when tracking is not corrected, and will rather quickly lead to arcing.

|

Undetected corona can lead to a further deterioration of the insulator and lead to tracking and eventually flash over |

The move from corona to tracking leads to a destructive path across the insulation, and creates pin-holes and spider web-like tracking which causes surface deterioration. When visually inspected, one can see a very obvious tracking path on the surrounding surfaces. Also, a conductive cloud of ionized air surrounds the connections. Flash-over can now occur once a tracking path is complete from phase to phase, or phase to ground.

The following images show findings from an ultrasound inspection on a metal-clad piece of switchgear. Ultrasonic noise was detected from the B-phase and was further investigated.

|

Ultrasound inspection in progress |

|

|

|

|

Limited direct line of sight– ultrasound showed noise originating from B-phase fuse stall |

|

|

|

|

De-energized switch, open front of cabinet for visual inspection |

|

|

|

|

Further investigation noted that the B-phase, top fuse holder was touching the insulation board |

|

|

|

|

Tracking with early stages of arcing was discovered |

Arcing

Finally, arcing happens when there is a discharge to ground across an insulator. Arcing causes severe damage to equipment, plant/facility operations, and people. Melting of connectors, damage or loss of insulation, and fires usually result from electrical arcs. Arcing can easily be heard and detected with ultrasound. The sound characteristic for arcing is a rather erratic bursts of discharges and popping sounds. These are identifiable when looking at a recorded ultrasound of arcing in the Time Wave Form.

Arcing as seen in the Time Wave Form. Notice the lack of

uniform harmonics and the sudden starts and stops of the discharge

Conclusion

Ultrasound instruments are versatile and easy to use, and can greatly enhance the inspections of metal-clad switchgear. In the end, it’s all about safety. Ultrasound inspections can be done prior to opening the energized gear to scan with infrared. If an ultrasonic emission is heard, then the proper precautions can be taken before opening the energized cabinet. Also, for those that rely on the services of an outside contractor to perform infrared scans, an ultrasound scan can be done in between the annual infrared scan to see if any emissions are heard. When ultrasound and infrared are used together, an inspector is given a greater chance of detecting anomalies that could potentially be missed when relying on just one single technology.