Selecting, Specifying,and Purchasing Infrared Imagers

R. James Seffrin, Director

Infraspection Institute

425 Ellis Street, Burlington, NJ 08016

Tel. 609-239-4788 / Fax 609-239-4766

Introduction

Buying a thermal imager can be a daunting task for a seasoned thermographer; it can be especially difficult for the less experienced. Because the success of an infrared inspection program is dependent upon the chosen test equipment, it is imperative to select proper equipment. Knowing how to correctly specify and choose proper test equipment can help to avoid a costly purchasing mistake and ensure the success of an infrared inspection program.

As infrared thermography gains wider acceptance among maintenance professionals, its usage is increasing. Meanwhile, the task of selecting an imager is becoming more difficult. Thermographers now have a wide selection of equipment available from a record number of manufacturers. With the advent of lower cost microbolometer imagers, there are more choices than ever before.

Procuring an imager is a challenge for many reasons: initial purchase price can easily run into the tens of thousands of dollars, no imager is capable of performing all imaging applications, imager performance varies widely, performance specs are not always available or comparable, and making an incorrect purchase can be costly.

Purchasing an imager should be done by assessing your company’s present and future needs, obtaining and comparing manufacturer specifications, and taking time to thoroughly evaluate the imager in the workplace where it will be used. The following is a step-by-step approach designed to guide you through the purchase process from initial consideration to final decision. In general, the steps are listed with the most important considerations listed first.

Determine Appropriate Spectral Response

Prior to selecting an imager, it is imperative to determine the application(s) for which the imager will be used. Whenever possible, consideration should also be given to potential future applications. One of the most important performance criteria for infrared equipment is spectral response.

Manufacturers of modern thermal imagers generally select one of two infrared wavebands in which equipment will operate. Imagers that operate in the near infrared, also called shortwave, have spectral responses between 2 and 5.6 microns. Imagers that operate in the far infrared, also called longwave, have spectral responses between 8 and 14 microns.

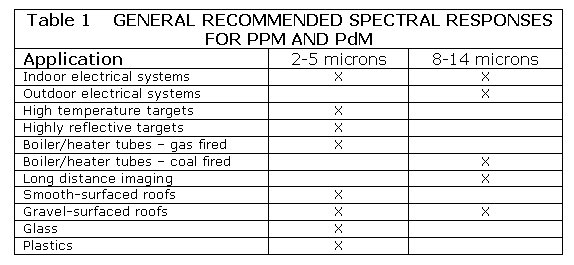

Spectral response is a permanent characteristic of the equipment and cannot be changed. Selecting equipment with proper spectral response is extremely important since many applications are wavelength specific. Choosing equipment with an incorrect spectral response may preclude the ability to collect accurate data. Table 1 shows recommended spectral responses for PPM and PdM applications.

Evaluate Objective Specifications

Objective specifications describe performance characteristics for a specific model line. These specifications are not changeable and will, in many cases, determine whether an imager can be used to successfully accomplish an inspection. Objective specifications are usually available from the manufacturer’s product data sheets.

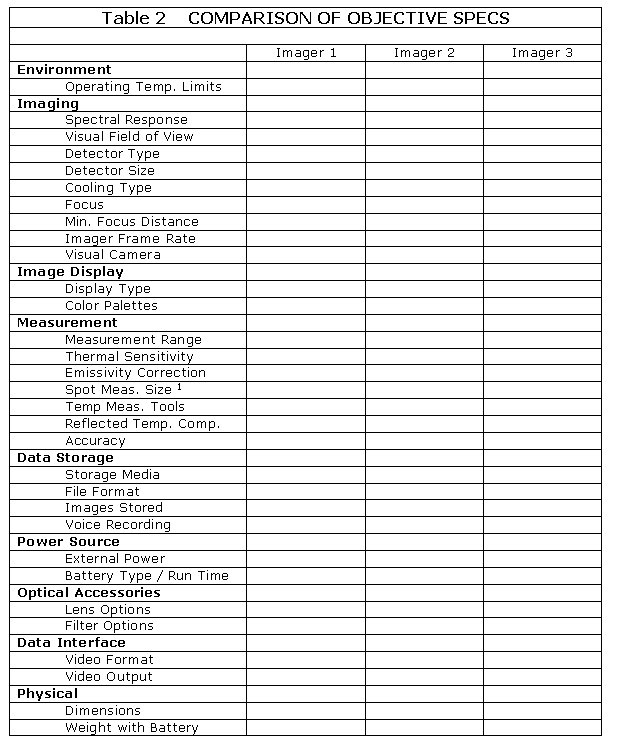

To best compare the objective specifications between thermal imagers, it is recommended that you refer to the manufacturer’s published data for the subject imager(s) and develop a spreadsheet noting as many specification values as possible. When completed, your spreadsheet will allow you to make relevant comparisons between the imagers being considered. Some of the most important objective specs are listed in Table 2. You may wish to add additional objective specs to those provided.

Note 1: For information on determining spot measurement size, refer to the Guideline for Measuring Distance/Target Size Values for Quantitative Thermal Imaging Cameras, available from Infraspection Institute, Burlington, NJ

Determine Performance Specifications

Performance specifications refer to how an imager operates in the field as well as the history of the subject model line. Historical information is usually available from the manufacturer; performance history is best obtained from references provided by others who own the subject equipment. Your manufacturer’s representative should be willing to provide the names of other users that you may contact for equipment reference. Some of the performance criteria to be considered include:

- Length of time the subject imager has been in production. It may be wise to delay purchasing a recently introduced model until after it has been proven to be reliable in similar installations.

- Obtain references from actual users of the subject imager.

- Physically try an imager before purchase. This can be accomplished by obtaining a loaner unit or renting the subject imager. Manufacturers may credit short-term rental fees toward purchase price. Be certain to thoroughly try the imager under the exact conditions you will encounter in your job.

- Ascertain software options available for the camera. Be certain that selected software is capable of performing the desired analysis.

Obtain Service & Warranty Information

In general, service and parts can only be obtained from the manufacturer of the subject equipment. Because calibration procedures are proprietary, calibration adjustments can only be performed by the camera manufacturer. Since service is not available from third parties, the success of your infrared program can be greatly affected by the ability of a manufacturer to service and support your infrared equipment. Prior to purchase, consider the following:

- Manufacturer’s experience in building and servicing infrared equipment and capability to provide future service

- Recommended service or calibration frequency and anticipated costs

- Expected delivery time for any required repairs

- Length of warranty and covered parts

- Location of equipment service centers

- Loaner/rental availability during repair periods

Evaluate Imager for Subjective Characteristics

Subjective characteristics describe how the imager feels to the operator. Since you may spend considerable time with your chosen imager, comfort will be important. When evaluating an imager, you should consider the following:

- Are imager controls easy to use and understand?

- Is equipment designed to be rugged and durable?

- Is imager ergonomically comfortable?

- Will imager size or weight present problems for long-term usage?

- Is the imager display clear and free of noise and distortion? Although this is one of the most important considerations when selecting an imager, there is no methodology for assigning an objective value to image quality.

- Is imager display adequate and compatible with operator’s safety glasses or other personal protective equipment such as hard hats, face shields, hoods, respirators, etc.?

- Is the imager display viewable in direct sunlight?

Equipment Cost

From a performance standpoint, cost should be the least of one’s considerations when purchasing equipment. Equipment which is incapable of accomplishing a task is no bargain at any price. For many infrared cameras, cost is often negotiable as are items such as extended warranty and service contracts. For a comprehensive list of equipment manufacturers, please visit www.irinfo.org.

Once you have made your final selection, be sure to obtain quality certification training for your thermographers. For new users, training should include infrared theory and heat transfer concepts, equipment operation, image capture and analysis, standards compliance, applications specific inspection techniques, documentation of findings, and temperature measurement techniques. For more information on infrared training and certification, contact Infraspection Institute at 609-239-4788 or visit us online at www.infraspection.com.

Advertisement