Infraspection Institute

425 Ellis StreetBurlington, NJ 08016Tel. 609-239-4788www.infraspection.comIntroduction

Successful thermography begins long before the actual field work begins. The final results for any project depend upon understanding the task(s) to be performed, selection of equipment, operator skills, inspection techniques, and documentation of findings. Failure to understand how these factors contribute to the final conclusions can lead to serious errors. To ensure optimum results, a thermographer needs to understand the nature and reason for the inspection, all equipment and operator limitations, site conditions and how to properly document his/her findings.

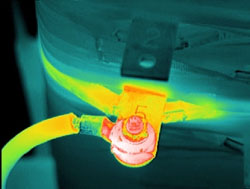

that are detectable with thermal imaging.

The use of infrared thermography for predicitve maintenance (PdM) and condition based monitoring (CBM) is now widely recognized. The benefits of infrared thermography coupled with lower equipment costs have led to a greater public awareness of common applications. Research continues to broaden the applications of thermography. Advances in equipment now allow thermographers to routinely perform tasks that could only be dreamed of as little as ten years ago.

Common applications of infrared thermography now include electrical and mechanical systems, building envelopes, insulated roofs, petrochemical processes, transportation and medicine. Regardless of the application, the final results depend upon understanding the task to be performed, selection of equipment, operator skills, inspection techniques, and documentation of findings. Before embarking upon a project, a thermographer needs to consider and understand how these factors will influence the final results. With this article we will outline the basic elements that a thermographer needs to consider for a successful project.

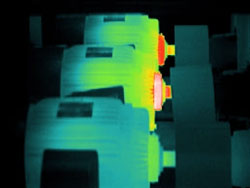

rapidly assess operating motors.

Note overheated bearings.

Defining the Task: Perhaps the most important and often most overlooked part of thermography is defining the project. Before any successful task can begin, the thermographer needs to determine exactly what is to be done and what is expected of the final results. This usually entails meeting with the end user to discuss the subject of the inspection, any recent problems and history related to the project, and what is expected of the results.

In the case of a commercial flat roof, a client might ask a thermographer to “Conduct an infrared scan to locate wet areas”. While this might seem to be a straightforward request, it does not adequately define the task. From this request it is unclear when the work is to be performed, what type of imager is be used, whether the work is to be ground-based or from an aircraft, if invasive verification is to be included, or what type of documentation is required.

Regardless of project type, it is always desirable for the thermographer to work with the end user so that all aspects of the project can be defined. If the project requires skills beyond thermography such as roof core sampling, the thermographer, if qualified, may elect to perform these tasks or work with others who are qualified. Once the exact nature of the task has been determined, a scope of work can be developed to define the project in a written format..

A proper scope of work serves as the blueprint for all aspects of the project. It defines what is to be done and why, it describes which published standards are to be followed, it describes when and where the project is to be conducted as well as who will perform the work. In short, a proper scope of work ensures that all parties know what is to be done and what can be expected at the completion of the project.

Applicable Laws and Codes: Before accepting a project, a thermographer must determine whether any part of the scope of work is governed by local laws and/or codes. In some locations, thermographers are not legally permitted to perform electrical voltage and ammeter readings since this is considered electrical work and persons must be licensed to perform electrical work. In such cases, a thermographer could elect to work with a qualified professional in order to jointly complete the project. Regardless of the type of infrared inspection, it is the thermographer’s responsibility to comply with all applicable laws and codes.

Thermographer Qualifications: Perhaps the greatest limiting factor in thermography is the thermographer. Although thermal imagers each have their limitations, thermographers can overcome this by selecting the proper equipment. This will be discussed later.

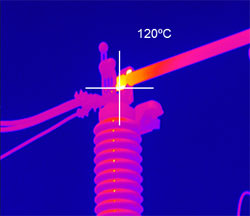

used to qualify the operating condition

of inspected components.

Since the thermographer is the most important factor in hermography, knowledge is of utmost importance. Unless otherwise specified in the scope of work, it is usually not enough for a thermographer to understand only how to operate a thermal imager to produce thermograms. At a minimum, thermographer should have completed a Level I thermography training course. Thermographers who perform inspections involving temperature measurement should be trained to at least Level II.

The professional thermographer needs to have a thorough understanding of infrared theory and heat transfer principles and how site conditions and weather can influence results. At a minimum, a thermographer must also have a basic understanding of the equipment or systems to be inspected. When a thermographer is unfamiliar with the items to be inspected, it is his/her responsibility to gain the knowledge necessary to properly conduct the infrared inspection.

A thermographer must always be an expert in his/her field and be able to honestly recognize personal limitations. Anything less compromises the final results of a project before the inspection begins.

Equipment Selection: Perhaps the second greatest limiting factor in thermography is the thermal imaging equipment. Even the best thermographer cannot compensate for equipment that is not capable of producing the desired information. Fortunately, today’s wide selection of equipment provides many choices for accomplishing the task. Modern thermal imagers offer features that not only make thermal imaging easier but provide more capabilities to the thermographer. Unfortunately, the wider selection of equipment tends to make the selection of equipment more difficult due to the large number of choices.

measurement accuracy.

Unless a scope of work specifies the equipment to be used, the thermographer needs to select the proper equipment for the task. Some of the more important criteria for the selection are the spectral response of the imager, color options, visual and measurement fields of view, radiometric capabilities, operating limitations, and image recording. The use of accessories such as filters, heat shields and special lenses might also be required. Other important considerations include operating temperature, imager controls, display screen, and whether the imager is intrinsically safe. When it comes to imager performance, cost should be considered last.

A thermographer must always be aware of the capabilities and limitations of his/her equipment. Equipment should be maintained in good working order and calibrated in accordance with manufacturer’s recommendations. A thermographer must also be able to honestly recognize limitations of his/her hardware.

Site Conditions: Prior to the actual conduct of the infrared inspection, all pertinent site conditions must be considered. Limitations regarding use of the use of photographic equipment might preclude the use of certain equipment. Other site conditions which need to be addressed are the accessibility of the equipment to be inspected, radiation levels, airborne particles, sterile requirements, and the presence of hazardous or explosive areas.

workers from electrical hazards.

It is the responsibility of the thermographer to speak with site safety personnel prior to a project to discuss all pertinent site conditions and determine how these conditions will affect the work to be performed. When working near energized electrical equipment precautions must be taken to protect personnel from electric shock and arc flash hazards.

Weather Limitations: Anyone who has worked outdoors can appreciate the effect weather can have on an infrared inspection. Intense summer sunlight during electrical substation inspections can make work more than a little difficult. High wind can completely obscure exceptions while precipitation usually cancels any plans to work outdoors.

Even when weather conditions are less than extreme, weather still plays a role in outdoor thermography. In the case of an infrared roof inspection, the amount of daytime solar loading and wind will have a direct effect on the post-sunset thermal patterns regardless of weather conditions at night. In some cases, daytime weather conditions can influence the subject structure or systems for several hours after sunset.

In order to ensure optimum results, a thermographer needs to understand and consider how weather conditions will affect final results. When weather is less than optimum, a work postponement may be the wisest decision. Additional Responsibilities: Due to client requirements or the type of project, many infrared inspections include responsibilities outside of thermography alone. Some common examples include:

-

Recommendations for repair of electrical hotspots.

-

Removal/replacement of electrical panel covers.

-

Ammeter/voltmeter readings.

-

Length of warranty and covered parts

-

Moisture meter readings and core samples during roof inspection.

-

Ultrasonic verification of steam trap failures.

These types of tasks are often coupled with an infrared inspection. In some cases, additional responsibilities are necessary in order to properly complete a project. As long as a thermographer is qualified and not prohibited by local laws and codes, he/she might consider performing this work directly. When a thermographer is not qualified to handle additional responsibilities, working with another qualified professional may be the best choice.

Documentation: The final documentation is the formal record of a project. Proper documentation details how and when an inspection was performed, who performed the work, weather conditions, any special procedures followed, the results of the work and conclusions. The report should also include all pertinent graphics, photographs and thermograms.

With the advent of more sophisticated imaging equipment and advances in computers, thermograms are no longer limited to monochrome prints. Color thermograms, video recordings and digital images are now more common. Laptop computers and powerful software enable the thermographer to prepare reports while in the field.

Since the possibilities are so varied, the thermographer should consult with the client before the project begins to determine which type of documentation is best suited to the client’s needs. Above all, the report should be clear and sufficiently document inspection techniques and site conditions in order that future inspections may be carried out under similar circumstances.

Limiting Liability: Whenever thermographers make recommendations in their reports, they accept a certain amount of liability which goes beyond the basic infrared inspection and subsequent documentation. Before offering recommendations in a report, a thermographer needs to carefully consider how much liability they are willing to accept. Depending upon location, providing recommendations may be considered professional engineering.

Professional engineering requires special insurance for professional liability. An experienced insurance agent can help to determine what type of insurance coverage amounts are appropriate for a thermographer. Your insurance agent should also be able to outline what type of recommendations are covered by your insurance. Depending on the type of information offered in a thermographer’s report, professional liability insurance may not be necessary.

Expert Witness: The ability of thermography to serve as evidence in legal cases has gained a wider acceptance in the last few years. Properly documented infrared inspections make compelling evidence with their ability to graphically present information the average person can’t see.

With today’s litigious society, chances are good that a thermographer could be called to testify in a legal case. Thermographers do not always appear in court by choice. Often thermographers are subpoenaed with little or no warning. At times, a rather insignificant or routine inspection is suddenly the centerpiece of a legal action.

By always properly preparing, executing and documenting an infrared inspection, the likelihood that a thermographer’s work will be allowed in court increases greatly. At the same time, the embarrassment that accompanies a substandard report is avoided.

Successful thermography begins long before the actual field work begins. The final results for any project depend upon understanding the task(s) to be performed, selection of equipment, operator skills, inspection techniques, and documentation of findings. Failure to understand how these factors contribute to the final conclusions can lead to serious errors. To ensure optimum results, a thermographer needs to understand the nature and reason for the inspection, all equipment and operator limitations, site conditions and how to properly document his/her findings.