Ed Kochanek

Director of Sales Eastern Region

FLIR Commercial Systems, Inc.25 Esquire RoadNorth Billerica, MA 01862Ph: 978-901-8000 www.flir.com/thermography/americas/us/ Abstract

Thermal imaging is a non-destructive test technique with numerous applications for structures and electrical and mechanical systems. Whether you are a building inspector, energy auditor, or someone interested in facility maintenance, the infrared camera is not your only tool. Visual inspections, moisture meters, and ammeters are all routinely used to help confirm the cause of thermal patterns. This presentation will look at several tools that complement the infrared camera and help you get the job done. This presentation will also discuss how these tools work and communicate together, making report generation easier and faster than ever before.

Discussion

Thermal imaging has come a long way in the last 15 years. The initial cost for a camera was above $50,000 thirteen years ago. Now you can purchase one for under $1,000. The industry has grown and consequently there are many more thermographers in 2014 than there were in 2000.

Now that you have your thermal imager, what is the next tool or instrument you should use? Finding the problem is only half the battle. Correctly diagnosing it and making a recommendation is just as important. This paper will discuss some of the most popular instruments used by thermographers to help you get the job done.

Electrical surveys of industrial plants or facilities are the most popular use of thermal imagers. So let’s look at a couple of instruments you should have in your electrical tool box and some features these meters need to have to work accurately in today’s complicated electrical environment.

Digital Multimeters

The digital multimeter (DMM) is one of the most common instruments you will find in an electrician’s or thermographer’s tool bag. After discovering a potential problem while using a thermal imager, the next step is to measures the voltage and/or amps. The DMM is used to troubleshoot electrical problems in a wide array of industrial and commercial devices such as electronic equipment, motor controls, power supplies and wiring systems.

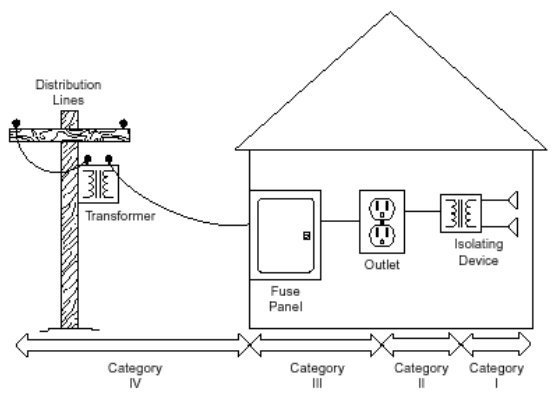

When considering the purchase of a DMM, one of the first criteria you need to decide is what safety rating you should get in the meter. A DMM is rated using 4 categories:

Category I – Isolating Device: This category is for measurements of voltages from specially protected secondary circuits. Such voltage measurements include signal levels, special equipment, limited-energy parts of equipment, circuits powered by regulated low-voltage sources, and electronics.

Category II – Outlet: This category refers to local level electrical distribution, such as that provided by a standard wall outlet or plug in loads (for example, 120 AC voltages for US or 220 AC voltages for Europe). Examples of Measurement Category II are measurements performed on household appliances, portable tools, and similar modules.

Category III – Fuse Panel: This category refers to measurements on hard-wired equipment in fixed installations, distribution boards, and circuit breakers. Other examples are wiring, including cables, bus bars, junction boxes, switches, socket outlets in the fixed installation, and stationary motors with permanent connections to fixed installations.

Category IV – Outdoors: This category refers to the origin of installation or utility level measurements on primary over-current protection devices and on ripple control units.

Resolution

Resolution refers to how fine a measurement a DMM can make. For example, a thermometer that only measures whole degrees is not useful when you are measuring body temperature and 98.6 is a critical value. You need a thermometer that measures to one-tenth degree resolution. The same is true of your meter.

For example, a DMM with a 3.5 digit meter can display 3 full digits from 0 to 9 plus 1 or zero in front. It also can be represented as 1999 counts. A 4½ digit meter can display up to 19,999 counts of data. Also, digits or counts should not be confused with accuracy. It just describes how fine a measurement you can make.

True RMS

In the past multimeters were averaging meters. Many of the low cost multimeters today are still only averaging meters. Averaging multimeters accurately read a pure sine wave generated by electrical equipment. However, with today’s sophisticated electronic and industrial equipment you may run into problems with this type of meter. The nonlinear wave forms created by solid state equipment such as variable frequency drives, fan controls, motor control drives, and industrial motors to name a few, are distorted. If that is the case, your meter will measure inaccurately, by as much as 40% below or 10% higher than the actual reading.

To avoid these problems you need a true “RMS” meter. RMS stands for root mean square. A true RMS meter will accurately measure these types of waveforms.

Even our homes – the last location of clean sine waves – are now subjected to nonlinear wave forms from computer equipment, fluorescent lights, etc. If you are a residential electrician you should spend the extra money to get a True RMS DMM.

Ghost Voltages

Ghost voltages occur from having energized circuits and non-energized wiring located in close proximity to each other, such as in the same conduit or raceway. The most common places to encounter ghost voltages are blown fuses in distribution panels, and unused cable runs or electrical wiring in existing conduit. This situation would cause your meter to measure inaccurately since the meter is measuring voltages coupled into the disconnected conductor in these long raceways. You may only see 80% of the voltage you would expect.

A DMM with an LoZ (low impedance) mode on your DMM gives you the ability to actually see if there is any voltage present. When the leads are placed on an open circuit that contains a ghost voltage, the low input impedance will cause the ghost voltage to dissipate and the meter will display a reading near zero volts indicating that there is no voltage present.

Variable Frequency Drive (VFD)

If your industrial plant or facility has a lot of electronically controlled motors, most commonly referred to as variable frequency drives, you may need a meter that has a VFD or low pass filter. A VFD environment is a high energy and noisy environment. You should look at a meter that has a low pass filter that allows the meter to make accurate drive output measurements that will agree with the motor drive controller display indications. Taking measurements from the input side can be done easily with a traditional true RMS multimeter. Since VFD’s are more popular and common than ever you should really consider upgrading to a DMM that has a VFD mode feature.

Remote Viewing

A new feature in DMMs today is remote viewing. These meters do it wirelessly via an additional remote screen or using bluetooth to an Android smart phone. Remote Viewing is a nice time saving feature, especially when measuring and making adjustments are in two different locations. Another nice benefit is the ability to email this data since the Android can act like a data logger and use its cell service to send out critical information via email immediately.

MeterLink

When using a DMM as a secondary verification tool it’s nice to collect all this information in one place. MeterLink gives the thermographer the ability to collect the important meter data and log it on the thermal jpeg image. This jpeg can then be shared in an email or report that documents the problem.

Clamp meters have improved over the years just like DMMs. In many cases the clamp meter has replaced the multimeter as the maintenance go to tool for making voltage and current measurements. That’s because the clamp meter has most of the same measurement capabilities as the DMM, but due to its design, measures amps much easier.

Since the clamp meter shares many of the capabilities of the DMM you can apply the feature criteria from the DMM section. However, depending on your application you should also consider some other features.

Inrush Motor Current

If you work around motors this is a feature you should consider. Motors are more efficient today and therefore use less electricity during normal run periods. However, the startup or inrush current can be considerably larger, up to 11 times as large compared to 7 to 8 times for an older motor. Not all clamp meters can measure inrush current accurately. You should check to see if the clamp meter has an arming function where it can be ready to measure the beginning of the current, which is where most of the load is and it happens very quickly. A quick meter with this feature will give repeatable and accurate data.

Power Quality

In AC circuits, the power factor is the ratio of the real power that is used to do the work and the apparent power that is supplied to the circuit. When you have a low power factor you draw more current for the same amount of useful power transferred. Low power factor can be caused by inductive loads from motors, transformers, and high- intensity lighting. Since utilities can charge higher fees for power factors less than .95 it’s important to find these problems and correct them.

Harmonics

Harmonics occur when current flows in a circuit at multiples of the fundamental 60 Hertz frequency. These currents are not directly indicated on a meter and are usually not found until unusual conditions and equipment problems begin to surface. Look for a clamp meter that has the ability to measure harmonics. This will save you time in solving these problems.

Motors – What other tools

One of the most common thermal targets is industrial motors. Motors account for a large percent of the energy used at an industrial plant. Infrared  imagers are very good at spotting the clues to a motor failure. However, verification with a second tool is sometimes necessary when evaluating the health of a motor. You should consider these tools as well:

imagers are very good at spotting the clues to a motor failure. However, verification with a second tool is sometimes necessary when evaluating the health of a motor. You should consider these tools as well:

- Motor tester to verify the motor condition, winding integrity, and insulation isolation

- Tachometer to verify the motor shaft speed

- Phasing meter for motor rotation and machine verification

A useful tool for the thermographer is the anemometer, which measures air or wind speed.

Anemometers measure moving air with a rotary sensor which acts very much like a weathervane and can be likened to the blades of a fan. The vane freely rotates in response to air flow and as the air moves through the vane, the blades turn in proportion to the speed of the air.

This instrument is useful while working outdoors when you find a hot spot in an electrical substation. The faster the wind speed the cooler the object will be. As soon as the wind dies down the temperature of the object will increase. If you are not planning to be back and take an accurate temperature measurement, you may want to correct for wind speed.

Winds speeds as low as 3-6 mph can cool a target down by 10 degrees. It’s helpful to make this notation when submitting a thermographic report.

Moisture Meters

A common use for a thermal camera is to detect water in building materials. A wet environment leads to unhealthy living and working conditions. The thermal camera has replaced the moisture meter for finding water quickly and easily. Unfortunately, the camera will detect the effects of moisture but it won’t confirm the presence of it. Therefore, the moisture meter is still necessary to confirm the findings.

Moisture meters sense, measure and display the moisture content of wood and other building products. Materials such as sheet rock, wall board, mortar, concrete, plaster, cardboard, and others can be tested for moisture.

Some of the new moistures meters have MeterLink and Wi-Fi for instant reporting and verification. This is useful when having to report your findings in a timely manner.

First Surface Mirror

If you need to see a target that is hard to reach or in an area blocked in view from the imager, you should consider a first surface mirror. This type of mirror has the reflective coating on the top side and not behind the glass as in a typical (or second surface) mirror. Since the glass of a typical mirror is not a perfect reflector of long wave radiation, your reflected view would be distorted.