Fred Baier

Level III

Certified Infrared Thermographer

Delta T Engineering, LLC.

136 Main Street

Metuchen, NJ 08840

Abstract

Thermography is a proven technology for detecting elevated temperatures within operating electrical distribution systems. Typically performed on an annual basis, infrared inspections can detect evidence of overheating caused by loose/deteriorated connections, overloaded circuits, and imbalanced loads.

While infrared inspections can be valuable in helping to prevent unexpected failures, they provide a single “snapshot”, leaving the subject components unmonitored for the balance of the year. Recent advances in technology have resulted in wireless sensors that monitor for the same types of defects that are detectable by thermal imaging. When permanently installed on electrical enclosures, these sensors can provide year- round monitoring of electrical system components and can immediately alert personnel when problems arise.

This paper will discuss the theory and application of the Delta T Alert monitoring system and how it can be used to complement and enhance the effectiveness of an existing infrared inspection program within commercial office buildings. Installation and set-up procedures of the system will be discussed along with actual case studies.

Introduction

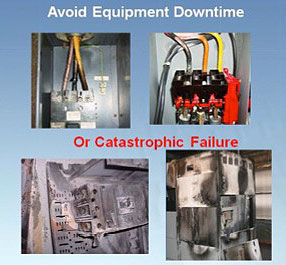

In the highly-competitive world of commercial building management, your success depends on high tenant occupancy, controllable expenses, and trouble-free operation. That means no unexpected shutdowns, no major equipment or service failures, and no expensive emergency repairs.

The heartbeat of any commercial building is its electrical distribution system, which regulates water pressure, climate, communications, and lighting. Without this heartbeat, all services stop – along with your business. Facility downtime is not an option if you want to keep your tenants.

According to Hartford Steam Boiler Inspection and Insurance Company (HSB), (www.hsb.com), electrical system malfunctions are the leading cause of commercial building fires. These fires have increased in frequency and severity over the past two decades, due primarily to increased demand on existing electrical systems. Even newer buildings are not immune to electrical failures, as businesses demand an ever-increasing stream of power, placing more and more pressure on overloaded systems.

According to Hartford Steam Boiler, the number one cause of such failures is a lack of proper maintenance – or no maintenance at all. HSB reports that 75% of all electrical failures are due to human error or carelessness, deficient or delayed maintenance, unqualified personnel, and/or budget cuts. According to the Institute of Electrical and Electronics Engineers (IEEE) in New Jersey (www.IEEE.org), the failure rate of electrical systems is three times higher for those that have not had preventive maintenance than for those that have.

So Many Points – So Little Time

In a typical one-million square foot high-rise commercial office building, there are literally hundreds of electrical power and distribution panels, along with just as many disconnects. This equipment may receive an infrared scan once per year, at most, or an occasional “clean and tighten”, which is conducted during off hours. The “clean and tighten” procedure requires both an electrical shutdown and significantly higher electricians’ wages (time and a half or double time). It is a major expense and inconvenience for both building owners and their tenants.

Meanwhile, some experts do not recommend routine tightening of electrical connections. In many cases, over-tightening can deform the bolts and/or the contact faces, decreasing the surface contact area and producing greater resistance. Greater resistance can cause heat buildup, potentially damaging insulation and components.

Commercial facilities’ infrastructures typically have many safeguards in place such as: pump gauges, water tank level alarms, and smoke detection. In many cases, a property may have a Building Management System (BMS), which controls and monitors the building’s mechanical equipment, such as air handling and cooling plant systems, as well as lighting, fire extinguishing, and security systems.

Electrical distribution systems, however, are often overlooked because most of the facility’s electrical enclosures are inaccessible. Since many electrical enclosures cannot and should not be opened in the “on” or “energized” position, maintenance personnel usually enter an electrical switchgear room or electrical closet limited to their senses – sound, sight and smell – to detect signs of overheating. But, once a worker smells something burning or hears something arcing, significant damage has already occurred, and the level of danger has increased significantly.

Delta T Alert: A Safe, Reliable Solution

Delta T Alert: A Safe, Reliable Solution

You can avoid a major electrical breakdown – and significant financial loss – with the “Delta T Alert”. Developed by Delta T Engineering, LLC, this patented device magnetically attaches to your electrical equipment covers, monitoring the Delta T (temperature differential) between the interior of an electrical enclosure and the ambient temperature of the room that enclosure is in.

You can adjust the Delta T to collect data on a daily basis, at specific time intervals. The information is then transmitted wirelessly to an onsite computer for analysis. Whether your panels are located in a 20° warehouse in Alaska, a 100° switchgear room in NYC or a 65° data center in Tuscaloosa, the Delta T Alert can warn you of excessive temperature rise within your electrical enclosures before more serious problems arise.

A Simple Device with Staggering Results How it Works

Delta T Alert is a self-contained temperature-monitoring sensor that attaches magnetically to electrical enclosure covers. This sensor is designed to work on NEMA 1 enclosures which are constructed for indoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment and to provide a degree of protection against falling dirt.

Delta T Alert is comprised of two temperature sensors – one to monitor the electrical enclosure’s interior temperature and the second to monitor the room’s ambient temperature where the enclosure is located. To monitor the enclosure’s internal temperature, a 15/32″ hole is drilled into the cover of the enclosure after the cover is removed. Delta T is then magnetically attached with the interior sensor protruding into the panel 7/8 of an inch. Both the size of the hole and the length of the interior sensor conform to protection classification NEMA IP20. This classification protects against access to hazardous parts with a finger.

Delta T is then configured to collect data on a daily basis, at specific time intervals. The information may then be transmitted wirelessly to an onsite computer for analysis and trending. Delta T Alert will warn you of temperature rises within your electrical enclosures – well before more serious problems arise.

Software

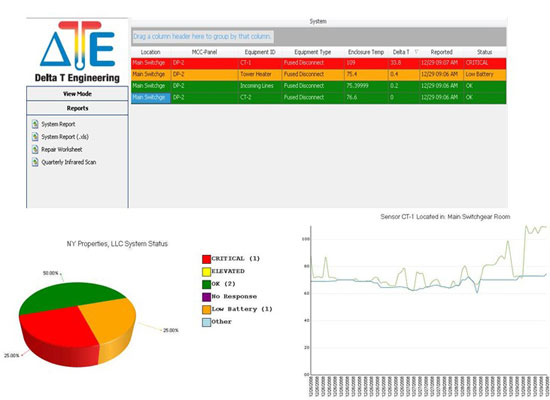

Our proprietary software will allow you to print reports and trending graphs, as well as scheduled repair logs for maintenance. Reports include the following:

- Total System Report

- Test Status Pie Chart

- Delta T Trending Graphs

- Repair Worksheets

- Infrared Scan Worksheets

Delta T Engineering’s software is capable of being bridged-over with most Building Management Systems (BMS) on the market today.

Delta T Alert – Advantages/Limitations

Delta T Alert is mainly designed to detect temperature increases within electrical enclosures caused by poor connections and overloaded circuits. Causes of poor connections include:

- Loose cable terminals

- Poor Crimps

- Corroded terminals and connections

- Loose, dirty, or corroded fuse clips on manual disconnect switches

- Loose, worn or poorly adjusted contacts in motor controllers or circuit breakers

Poor connections and overloaded circuits are directly responsible

for more than 30% of electrical failures.

Delta T Alert – Advantages

Delta T Alert is mainly designed to detect temperature increases within electrical enclosures caused by poor connections and overloaded circuits. Causes of poor connections include:

- Ability to record up to (8) readings per day at specific time intervals

- Readings recorded under different load conditions during all seasons

- Trending over time

- Reduced Energy Costs – Delta T Alert allows for the immediate repair of loose connections once detected. Loose and/or dirty connections create increased resistance which results in higher energy costs. The cost of cleaning and/or replacement of electrical components is low compared to the significant energy savings.

- According to Infrared Research Inc. – The average business may see a 1 percent to 4 percent savings in energy costs over a non-maintained system, (“Infrared Thermography Can Prevent Energy Losses,” Maintenance Technology, June 2001).

- Safety – maintenance personnel and/or electricians will have an enormous safety advantage if they are warned, prior to any routine maintenance or troubleshooting, of possible electrical anomalies prior to accessing electrical enclosures.

Delta T Alert – Limitations

Delta T Alert is not designed to detect:

- Under-voltage

- Harmonic Distortions

- Transients

- Instantaneous Anomalies

- Sags/Swells

- Minor Unbalance

- Disturbance Noise

- Is not necessarily designed for larger cabinets with set-back gear

Sample Report

|

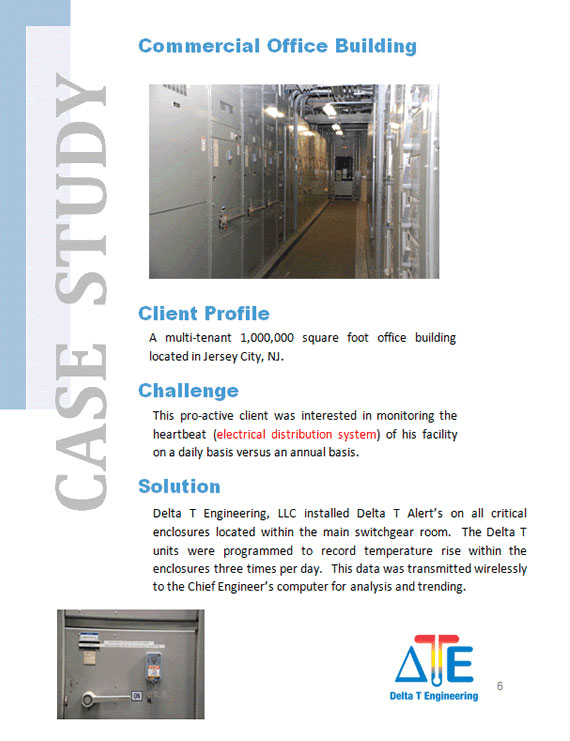

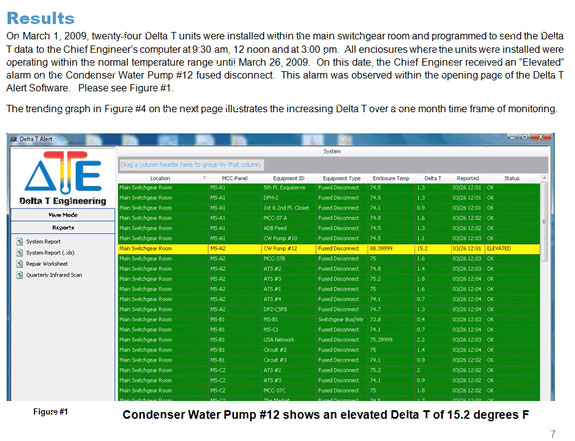

CASE STUDY

|

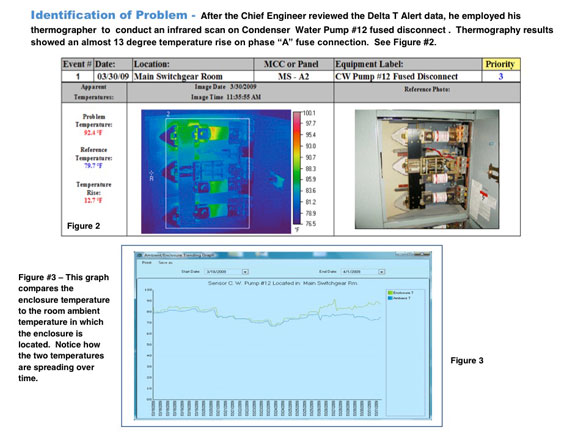

|

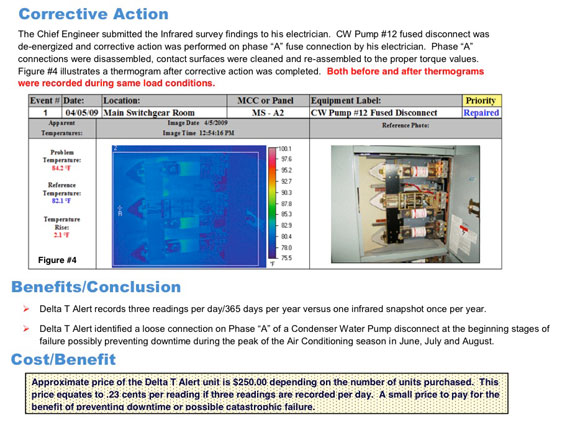

|

|

Conclusion

There has never been an easier, more cost effective way to keep your electrical enclosures operating safely. The Delta T Alert system will enable customers to Monitor – Report – Diagnose & Repair problems prior to downtime or even catastrophic failure. Your building’s maintenance personnel and/or electricians will have an enormous safety advantage if they are warned, prior to any type of routine maintenance or troubleshooting, of possible electrical anomalies prior to accessing electrical enclosures.

By utilizing Delta T Alert as a proactive maintenance tool, it is possible to extend the service life of electrical infrastructure as well as reducing the overall maintenance cost and associated downtime.