Adrian Messer

Manager of US Operations

UE Systems, Inc.

Ph: 864-224-4517Cell: 914-282-3504www.uesystems.com/newAbstract

Strategies for maintaining substation performance by spotting potential signs of trouble in advance is something many maintenance personnel contemplate. The implementation of predictive technologies such as infrared thermography and airborne/structure borne ultrasound go a long way in improving asset availability and reducing the surprise element of flashover incidents.

This presentation will focus on airborne/structure borne ultrasound as an effective tool for locating arcing, tracking, corona, and partial discharge events in substation equipment. Instruments based on this technology provide the ability to sense high frequency emissions produced by these potentially hazardous events and enable users to quickly find the source of the emission. Some ultrasound instruments have the ability to record sound events to be used for spectral analysis, which is becoming an important component of condition analysis and diagnosis of electrical emissions. After a brief overview of ultrasound technology, methods and principles of inspection and diagnosis will be discussed followed by examples and case histories.

Discussion

Ultrasound Technology

Airborne & structure-borne instruments give the inspector the ability to sense high frequency sounds that are not in the audible range, or the range of normal human hearing. Similar to the way that infrared cameras extend the sense of the inspector’s vision, ultrasound instruments extend the sense of the inspector’s hearing and allow the inspector to hear sounds that are not in the audible range. Ultrasound instruments translate high frequency sound into an audible sound that is heard through the headset by the inspector. The translated sound is then measured as a decibel level which is indicated on the display of the instrument.

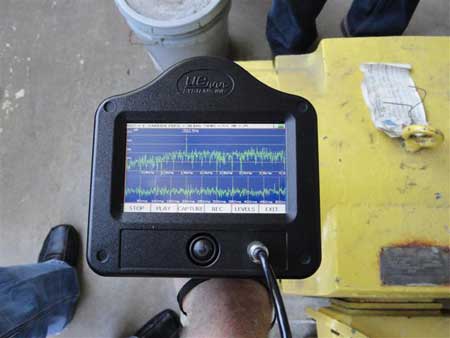

For further analysis, some instruments have on-board sound recording. Ultrasounds can then be recorded, and played back in a spectral analysis software to diagnose and confirm sounds heard by the inspector. Newer model instruments, such as the Ultraprobe 15000, actually have on-board spectral analysis. This allows for on-the-spot analysis and comparison of electrical emissions in the field. The analysis of recorded ultrasounds is the best, and preferred, method of diagnosing electrical emissions. This method reduces the subjectivity of only using what is heard through the headset to determine the severity of electrical ultrasound emissions.

Electrical Ultrasound Emissions

With regard to electrical applications, ultrasound can be used to listen for and detect corona, tracking, arcing, and partial discharge in electrical components. These emissions are created from the turbulence produced by the ionization of air. The components to be inspected can range from low, mid, and high voltage systems. Typical ultrasound inspections in a substation would include the transmission lines, insulators, circuit breakers, transformers, and disconnect switches, just to name a few.

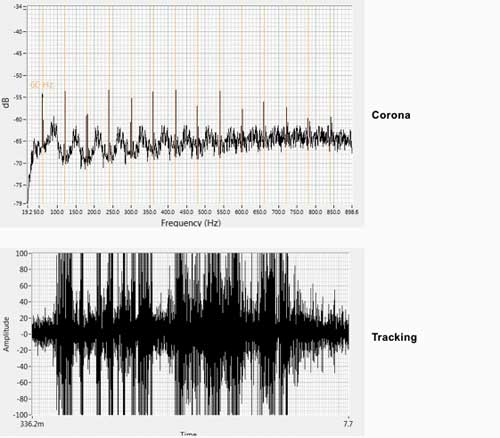

Corona discharge occurs from the ionization of air surrounding an electrical connection. This event will only occur in voltages exceeding 1000 volts. Ionization produces no heat; therefore, it is not detected with a standard infrared camera. Corona, when not corrected, will only lead to a further breakdown of the insulating material and connections. This is primarily due to the byproduct of the ionization process, nitric acid. Another threat caused by corona discharge is ozone. Damage to insulating materials, O-Rings, seals, and internal breakdown of transformers can occur as a result of ozone created by corona. It is heard as a steady, uniform, static-like buzzing sound.

|

Tracking occurs when there is a low current pathway to ground across an insulator. Many will refer to tracking as “baby-arcing.” This event is common where there is severe breakdown of the insulating material and loose connections. Tracking can occur in low, mid, and high voltages and characterized as a steady buzzing sound with periodic “crackling” and “popping” sounds. Further damage is done when tracking is not corrected, and will rather quickly lead |

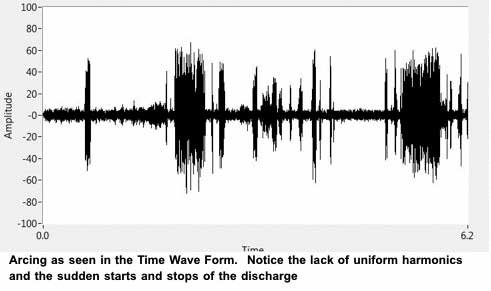

Arcing happens when there is a discharge to ground across an insulator. Arcing causes severe damage to equipment, plant/facility operations, and people. Melting of connectors, damage or loss of insulation, and fires usually result from electrical arcs. Arcing can easily be heard and detected with ultrasound. The sound characteristic for arcing is rather erratic bursts of discharges and popping sounds. These are identifiable when looking at a recorded ultrasound of arcing in the Time Wave Form.

Inspection of substations with ultrasound can easily be performed by trained inspectors. Airborne ultrasound emissions do not travel very far from the source, so they are easily pinpointed by the ultrasound instrument. A Long Range Module or Parabolic Dish can be used to listen to components that are in excess of 90′ to 120′ away. An ideal method of inspection would be to use ultrasound first to listen for any electrical ultrasound emissions, and then to use an infrared camera to look for hot spots and resistance. Either way, ultrasound is a perfect complement to infrared inspections of electrical components.

In the example below, ultrasound inspection was performed on a substation. The picture shows where two sounds were heard on the insulators. Both corona and tracking were detected with ultrasound. The corona was corrected by cleaning both the insulator and the surrounding connections. To correct the tracking, the insulator had to be replaced due to cracking.

The images below are from the recorded ultrasounds from this transformer.

Conclusion

In conclusion, ultrasound is a versatile and easy-to-use technology that can enhance the electrical inspections of anyone in the power distribution, generation, or electrical inspection industry. Enhancements to ultrasound instrumentation and software allow for easier diagnosis of electrical ultrasound emissions. With the use of ultrasound and infrared together, the inspector has the greatest chance of finding almost any electrical fault or condition, and allows for detections to be made much sooner, before catastrophic failure is imminent.