Ed Kochanek,

Director of Sales Eastern Region

FLIR Systems, Inc.

9 Townsend WestNashua, NH 03063Ph: 978-901-8000www.flir.com/thermography/americas/us/

Abstract

Infrared camera manufacturers have always looked to the current technology of the day to inspire their camera designs. This presentation will discuss how past innovations were incorporated as solutions to help thermographers do their job. We will also look at today’s technology and see how Wi-Fi and Bluetooth technology are currently being used to help communicate our findings in a real-time environment. Lastly, we will discuss what the future may bring with infrared camera design and how it may be used in the future.

Introduction

Thermal imaging got its start in the 1940’s. The primary use at that time was for military applications. It wasn’t until the mid-1960’s that thermal cameras were created for commercial and industrial applications. It took many years to achieve the designs we have today. Each innovation was a series of small technological improvements that built upon themselves to offer features making them easier to use. This article will discuss the highlights from the 1960’s to the present and attempt to make a prediction of the future of thermal imagers.

The Beginning

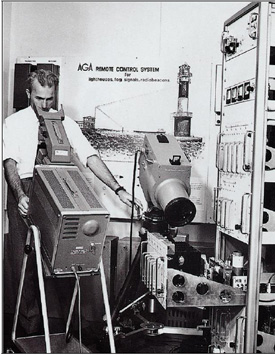

In 1965 AGA created the model 650 which was the first camera for predictive maintenance. An industry was born. The 650 was a very large unit, using a modified

|

|

|

|

Figure 1 |

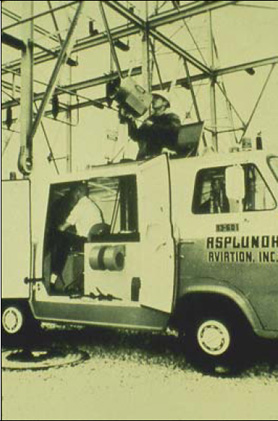

Figure 2 |

oscilloscope for a display. The utility industry was one of the early adopters of thermal imaging. As we can see in Figure 2 the camera was mounted on a van for substation inspection. Asplundh, who is pictured on the van, still offers this service today. The infrared camera was also used to inspect homes for missing insulation and heat loss. This was prevalent in Europe where they have always been ahead of the curve for home weatherization advancements.

As with all first designs, the goal was to make the cameras as easy to use as possible. The opportunities were endless and it was just a matter of time for the first new feature.

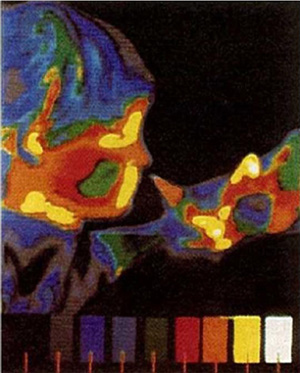

For instance, one year later AGA figured out how to add color to the image as seen in this picture. This was difficult because you needed to take 9 different pictures and merge them together. Color infrared has always been a polarizing topic. Color makes it easier for someone who is seeing an infrared picture for the first time to understand the differences in temperatures. However, with early cameras, color made it harder to focus because it made the image noisier than traditional grayscale. It wasn’t until the late 1990’s that camera image sensitivity improved enough to allow color to be desired full time by the thermographer. Up until then, most users preferred grayscale to scan and color for the reports.

Hand Held

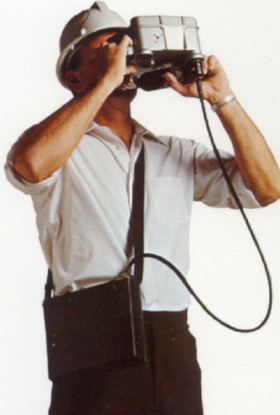

During the 1970’s manufacturers tried to address two main concerns: power and portability. As we have seen from the previous images, cameras were mounted on tripods and had to be plugged in for power. They were big, bulky, and very heavy. This obviously restricted movement and applications.

The AGA 750, introduced in 1973, was the first battery powered system. In 1974 Hughes introduced the Probeye. Removing the power cord allowed you to take the camera anywhere you wanted. The thermographer was only limited to how long a battery charge would last. Batteries were problematic up until the late 2000’s. They were either too large and heavy or too small and inadequate.

|

|

|

|

Figure 4 |

Figure 5 |

The Probeye was very popular with over 5,000 manufactured. It was also lower in cost compared to the other cameras on the market. As recently as October 2012 there was a Probeye 650 listed on eBay for $800. The camera came complete with everything a thermographer could want – camera, argon canisters for cooling, polaroid camera, and film for capturing that perfect image.

Long Wave

Most of the camera systems prior to 1980 were mid-wave systems. Mid-wave cameras operate in the 3-5 micron section of the electromagnetic spectrum. This presented a problem with solar radiation during the day. When using a mid-wave camera outdoors, you had to be certain that the hot spot was not a reflection from the sun. This was a big problem for the electric utilities who basically scheduled their scans for early in the morning or after sun down to reduce the chance for error. Some utilities still scan during these hours today!

The first camera to help mitigate solar reflections was the ISI Videotherm in 1980. It was a long wave camera sensitive to radiation from 7-13 microns. This camera also did not need liquid nitrogen to operate. The detector was an uncooled pyroelectric vidicon. This camera created an image based on the change of infrared radiation from the source. The downside was that if the camera wasn’t held still you lost your image because the radiation would not change that rapidly. Therefore, you always had to keep the camera moving to acquire an image. Future versions of this type of camera and detector added a spinning slotted wheel, called a chopper, inside the camera that created the change in radiation necessary for the picture.

Software

In the early 1980’s software was introduced. Both Agema (formally AGA) and Thermoteknix introduced software to complement the infrared camera. Software gave the thermographer the ability to plot out temperature line scans. It also gave them the ability to print out color thermograms. Software today is an integral part of the thermography experience. Customers of all types expect a report from the thermographer to detail what problems were found.

Whether the software is on a computer or smart phone, report generation has improved greatly. For most of infrared history, thermographers would spend as much time creating reports as they did in the field using their camera. Report generation was very time consuming. Enhancements to the cameras and software have dramatically increased the efficiency of this task. In fact, many cameras on the market today can create the report instantly inside the camera and be emailed via a smart phone the thermographer is using. Report generation today can take as little as 5% of the thermographer’s time.

Temperature

Today we take temperature measurement on an infrared camera for granted; however, that was not always the case. For about the first 20 years, instant measured temperature on a thermal camera was a dream. In 1984, Inframetrics introduced the first battery powered portable thermal imaging camera and measurement system displaying on-screen temperature measurement.

The Thermographer had to be aware of the dynamic range of the camera to make sure the temperatures they were seeing were within the camera’s scale. If the temperature was outside the range, the image would saturate and the measurement would be wrong. Color palettes were conceived to help the thermographer understand when something was above or below the range. These were called saturation palettes. For example, the target would be in grayscale with a red alarm color representing what was above the dynamic range and a blue color below the dynamic range. Today’s long wave cameras have large dynamic ranges and rarely are temperatures outside a given range. To replicate those saturation palettes, manufacturers have come up with isotherms that allow the thermographer to set his own temperature alarms.

One Piece Design

In 1987 Agema introduced the first system that thermographers would recognize today. The Agema 470 was the first handheld, single piece, battery operated thermal imager with measurement and digital storage. It took 24 years since the introduction of the first camera to get everything in one package; however, there was one drawback, it was heavy. The Agema 470 weighed about 20 pounds and came with a monopole for stabilizing the camera on the ground. This camera design was so popular and durable there are still cameras of this type in operation today.

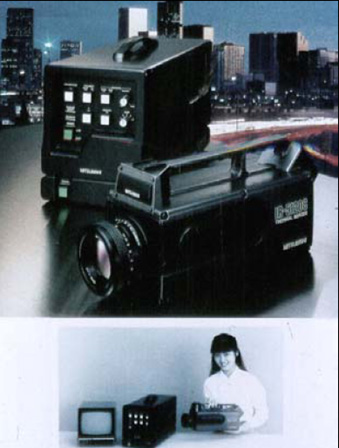

1987 also saw the first mid-wave focal plane array (FPA) Stirling cycle cooler introduced by Mitsubishi. Prior to this, all cryogenically cooled cameras required liquid nitrogen to operate. Thermographers always had to know how much liquid nitrogen they had and to make sure they did not run out. Also, the hazard of handling the liquid disappeared as well. The Stirling microcooler design would eventually allow companies such as Inframetrics, Agema and FLIR to produce amazing cameras over the next several years.

Mitsubishi introduced a unique array size that had over 262,000 pixels. This was the first time that a camera had all of its detector elements sensitive to infrared radiation. Most FPA’s after this camera were around 76,800. It would take another 20 years to duplicate the array sizes larger than this.

An emphasis in the 1990’s was to make cameras smaller and more portable. The Inframetrics InfraCAM was the first camera that used off-the-shelf camcorder batteries. It was also the smallest camera ever built. Inframetrics drove this point home using female models to advertise the camera.

Soon after this, all three camera manufacturers introduced high performance focal plane array cameras that were easy to hold, provided accurate temperature measurement, and had digital storage.

Since these new systems sold for over $50,000,Infrared Solutions (ISI) saw there was an opportunity for a lower cost camera. In 1997 ISI introduced the IR Snapshot camera. This camera was priced just under $25,000 making it one half the cost of the current technology of the time. To create an image, the operator had to hold the camera in place as it saved an image. In about 5 seconds an image would appear. It was effective if the operator was patient. Because of its price?point, this camera became very popular.

Microbolometer

Also in 1997, the infrared industry changed forever. Agema introduced the first microbolometer detector manufactured in an infrared camera.

This detector is the foundation most hand-held cameras are based on today. The microbolometer offered long wave performance, without a cooler, allowing it to be smaller and run longer. It was also solid state with only a non-uniformity correction flag as its moving part. That’s the clicking sound normally heard during operation of this type of camera. This camera changed the thermal imaging business forever.

In 2002 FLIR introduced the E series microbolometer camera. It was the camera platform that allowed manufacturers to significantly reduce the cost of an infrared camera. This was the beginning of when cameras were introduced year after year with lower costs and more features. In 2002, the E series starting price was around $25,000 but after 5 years and thousands of cameras later, the price was below $10,000.

The E series was very popular with the building trades. The first industry that gravitated to this camera was the water restoration industry. Why? Because mold and consequences to human health were just being understood. Remediation companies responsible for drying out facilities and homes after water damage were being held responsible for any mold growth. The restoration companies needed an efficient way to scan large areas for moisture damage. Due to evaporative cooling, water is very easy to detect with an infrared camera and restoration companies could be assured that areas of damage were completely dry.

GasFindIR

In 2006 FLIR introduced the GasFindIR camera. This was the first hand-held camera designed specifically to find volatile organic compound gases. We know these types of gases as methane, propane, butane, etc. These gases are visible in the mid-wave band of the infrared spectrum. These gases are byproducts of the oil and gas refining business. The GasFindIR was designed to find large leaking gases very quickly. It would help augment current technology such as the TVA (toxic vapor analyzer). The TVA needs to measure each valve or target in a refinery. The problem is that there are thousands of these targets and the survey is very time consuming. The GasFindIR is able to scan large areas quickly and find those hard to reach areas easily.

In 2007, FLIR added to the GasFindIR camera platform by designing a camera to detect SF6, sulfur hexafluoride gas. SF6 is 23,000 times more potent than CO2 in trapping greenhouses gases. The utilities use SF6 as an insulation gas in their circuit breakers and GIS substations.

Wireless Revolution

By now many of us have smart phones, Apple or Android, to communicate via phone or email during work hours. Infrared cameras have adapted to this technology as well. Infrared cameras now have Bluetooth and Wi-Fi built right in.

Current infrared cameras can communicate with test and measurement instruments with Bluetooth. Whether it’s voice notes, moisture content, or load on a circuit, these data can be transferred wirelessly via Bluetooth from the instrument to the saved image on the camera. The benefit is reduced time in acquiring information for report generation. Also, sharing this information is quite easy since it’s embedded in the infrared image and can be viewed by anybody the image is emailed to.

Infrared cameras that have Wi-Fi come with free apps that allow the transfer of information in real time. The benefit is now having a remote screen for other individuals to see what the camera is showing. Wi-Fi also allows the transfer of images without the physical handling of the storage media. This improves the efficiency of image handling and report generation.

New Markets and the Future

So what is the new frontier in camera design? Obviously cameras are getting much smaller and success from other industries is driving down cost rapidly. For example, thermal imaging is now incorporated by many car manufacturers for nighttime driving assistance. Car manufacturers such as BMW, Audi, and Mercedes have incorporated analytics with the camera to alert the driver to oncoming danger. This allows the driver to operate safely at night while keeping his eyes on the road and not on the camera display.

Staying in the automotive world, thermal imaging is now a popular solution for traffic control. Since IR cameras are unaffected by sunlight glare, fog, or any other visual light distractions, these cameras are providing a service where visual light cameras struggle. When you come to a stop light, take a look and see if infrared technology has reached your local town. This device may help you make it to your destination faster and safer.

|

|

|

|

Figure 14 |

Figure 15 |

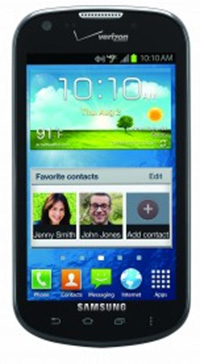

The next frontier I expect would be smart phones. Smart phone visual cameras are starting to rival expensive SLR cameras for image performance. Software for these cameras also allows for great image manipulation and panoramic views. In the near future, thermal cameras will reach a price point where the integration into a smartphone will be simple. These first systems will most likely provide qualitative image performance. The applications would probably center on personal safety. The ability to navigate in the dark while walking will provide a level of security not enjoyed today.

Also, simple fixes around the house could easily be done with a qualitative thermal imager. Heat loss and moisture detection to name a few could easily be accomplished with a small qualitative thermal imager.

|

|

|

|

Figure 16 |

Figure 17 |

New Markets and the Future

In conclusion infrared has come a long way since 1965. It has moved from a unique and exotic solution for the utilities, to possibly being on the next smart phone in the near future. However, there is one thing that has remained constant for the last 50 years – that is the need for competent and trained individuals to apply the technology to its fullest extent. Due to the laws of physics, emissivity, reflectivity, and transmissivity, the camera is still only as good as the user intends it to be. Regardless of the cost of the system, an infrared “champion” who is knowledgeable, trained and embraces the technology will always be needed.

Acknowledgements

I would like to thank Robert Madding, Gary Orlove, and Herbert Kaplan, whose paper “Twenty-five Years of ThermoSense: an Historical and Technological Retrospective”, and presented at Thermosense XXV was the basis for this paper. I would also like to thank Bernie Lyons and Gary Orlove, again, whose paper “A Brief History of 25 Years (or more) of Infrared Imaging Radiometers” was also a basis for this paper. Finally, I would also like to thank Frank Webb for helping me out with this paper as well.