Infrared Thermographer and Heater Integrity Optimization Engineer

Quest Integrity

10750 Cash Road

Stafford, TX 77477

Ph: 832-500-1031

www.QuestIntegrity.com

Email:

Abstract

Infrared (IR) thermometry has been used for forty years to monitor tube metal temperatures in refining and chemical furnaces. The application of IR thermometry has often been characterized as highly operator dependent and therefore developed a very poor reputation in the industry from poorly applied and interpreted results. There is no question that when absolute accuracy is unimportant, IR thermometry has proven to be an excellent diagnostic tool for detecting tube hot spots from internal fouling and heat distribution non-uniformity in fired heaters. However, to capture the full capability of IR thermometry, a proven methodology is required to measure accurate temperatures in a repeatable process.

Infrared (IR) thermometry has been used for forty years to monitor tube metal temperatures in refining and chemical furnaces. The application of IR thermometry has often been characterized as highly operator dependent and therefore developed a very poor reputation in the industry from poorly applied and interpreted results. There is no question that when absolute accuracy is unimportant, IR thermometry has proven to be an excellent diagnostic tool for detecting tube hot spots from internal fouling and heat distribution non-uniformity in fired heaters. However, to capture the full capability of IR thermometry, a proven methodology is required to measure accurate temperatures in a repeatable process.

Introduction

One of the hardest things in a marriage is getting couples to agree. Why is that? Simply, they each have their own opinion and they see situations through their own eyes. The same is true for infrared thermographers, it is unusual for two of them to agree on temperatures, reason being, they too see temperatures through their own eyes/instruments. Facts and opinions are different, although one spouse’s opinion is the house is cold, the other spouse’s opinion could be that the house is hot, the fact is, however, the house is 72°F. Wouldn’t it be great if we can agree to agree? Wouldn’t it be great if we could distinguish facts from opinions in the world of infrared? The great news is now we can. We now have the ability to get repeatable, accurate and reliable infrared temperatures for fired heaters. Not only that but these values can be obtained by any trained infrared thermographer utilizing any fired heater applicable instrument.

It’s About Time … and Temperature!!

When asked how you trust your temperatures, the most common answer I hear from infrared thermographers (including myself in the past) is, “based on my experience this is how much to correct the temperature.” Well, assuming a brand new infrared thermographer was hired who does not possess infrared experience, how would he know how correct the temperatures if his boss is not able to share his experience? Maybe your reply is, “He will just send a preliminary report until his more experienced boss can confirm the temperature corrections.” In another scenario, if two different infrared thermographers have different experiences and techniques of correcting temperatures throughout their career, how would one infrared thermographer be able to prove his experience is more valuable than the other?

If these questions are making you second guess your experience, then you would surely agree that it’s important for us to continue developing and understanding infrared technology in order to keep up with this fast-paced world. Although experience is a valuable asset, we need to study the science behind our experience.

Is it true that Quest Integrity developed software to quantify infrared temperatures? That is CorrectIR™

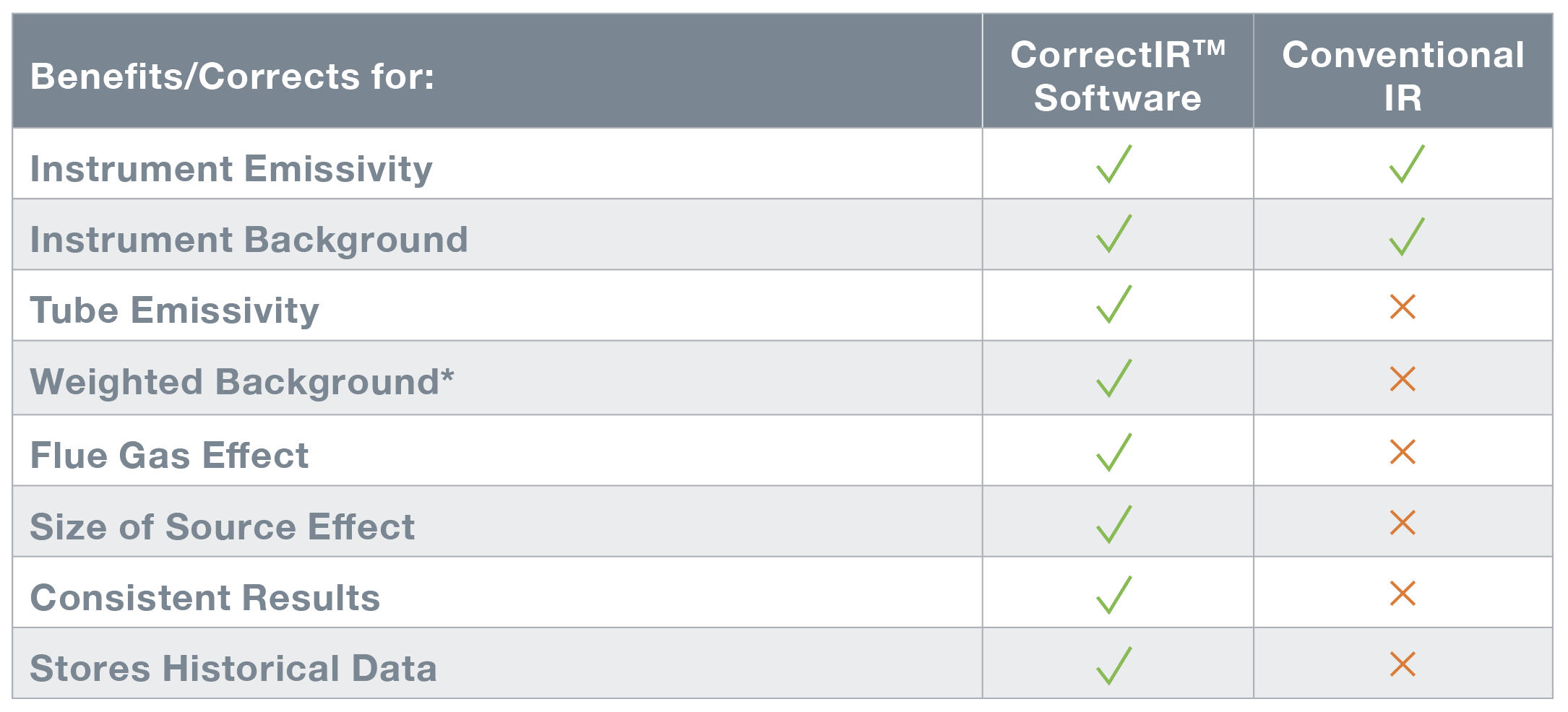

The main issue with infrared technology is that it is subjective. Quest Integrity took this challenge on by creating their proprietary software known as CorrectIR™. This software was developed to make temperature corrections based on models and theories developed by world-renowned infrared expert, Dr. Peter Saunders. CorrectIR™ is a science-based infrared approach that is widely recognized and adopted. With conventional infrared monitoring, the common temperature corrections factored are a single background temperature and emissivity. The following list shows the benefits and the temperature factors that the CorrectIR™ software takes into account when correcting raw temperatures.

*One important thing to note is that for the CorrectIR™ software,

the background temperature is not a simple one time reading of the hottest refractory/background; rather, it is a weighted average of all the surrounding temperatures that affect the target tube.

Infrared thermography and magazines have one thing in common; they both have issues. Unfortunately for infrared temperatures, if we don’t correct for all these measurement factors (issues), then we will not be able to have agreeable temperatures between two infrared thermographers.

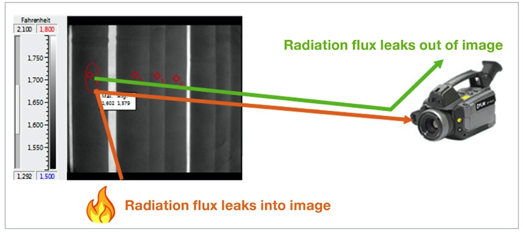

A common issue that is seldom corrected and needs highlighting is the size of source effect. This issue affects each infrared camera and each lens. Size of source effect (SSE) is when the radiation flux leaks into the detector from areas not captured in the image, which simultaneously causes radiation flux from the image to leak out of the detector (see Figure 1). SSE typically causes the radiance temperature to be higher than the actual radiance, i.e. the target tube will appear to have elevated temperature readings.

Figure 1. Size of Source Effect

To better emphasize this issue, when Quest Integrity calibrated a FLIR PM 390 infrared camera that measured a raw temperature of 1300°F using a regular lens, once the SSE is corrected for, the corrected temperature ends up being 1195°F. This demonstrates how significant SSE is. On a co-infrared thermographers FLIR PM 390 camera, using their regular lens and measuring a raw temperature of 1300°F, when they correct for SSE, their new corrected temperature is 1247°F. This is significant because when operating over design temperature, every increase of 20°F cuts your creep life in half. Keeping that in mind, allow me to demonstrate the following case study.

Challenge Accepted!

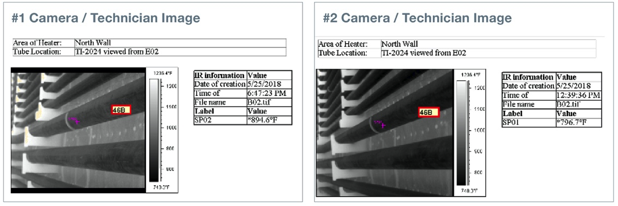

In this case study, Quest Integrity worked with another infrared company to demonstrate the repeatability, accuracy and dependency of the scientific methods that are applied in CorrectIR™. Both IR thermographers were to take images of the same heater at the same time with their own FLIR PM 390 camera. They were then asked to correct the raw temperatures utilizing the CorrectIR™ software (see Figure 2).

Figure 2. Case Study of an Ideal Spot Comparison

Which temperature do you trust and why? As you can see, the temperatures are almost 100°F apart. Suppose your experience tells you to correct temperatures by taking off 10%, then we would still have a significant difference. The reasoning behind these two temperatures is caused mainly by SSE. Now let us put our science to the test and plug these values in CorrectIR™.

After correcting the raw temperatures for all the measurement factors that were addressed previously, we end up with the following corrected results:

- #1: Raw Reading: 894°F -> Corrected Temperature: 716°F ±44°F

- #2: Raw Reading: 796°F -> Corrected Temperature: 706°F ±39°F

Let’s face it, the science works, but the bigger question remains. If my temperatures are low, why do I need CorrectIR™?

Obligation vs. Opportunity

When do more people usually go to the doctor? The common answer is, “when they NEED to.” This is the definition of obligation. Part of human nature is being content with meeting the minimum requirement, in other words, “if it ain’t broke, don’t fix it.” Unfortunately, what we fail to see are the opportunities that we could be missing by not being proactive.

If we were to be more proactive in going to the doctor, the likelihood is, we would be healthier. If we were to maintain our cars before we hear that indescribable sound the engine makes, our cars would last much longer. So when it comes to a fired heater application and CorrectIR™, the same is true. By knowing the true tube metal temperature, the owners of the heater will have a better understanding of how to optimize them; thus, with confidence, they may have an opportunity to increase production rather than simply cut rates. Besides, without a proven methodology, how can one be confident that temperatures are accurate? Also, in some cases, after corrections, raw temperatures increase rather than decrease, which means the corrected temperatures might put you over your liability limit. The goal of heater operators is inevitably to optimize the reliability and performance limits for their fired heaters (see Figure 3).

Figure 3. Balancing Reliability and Performance Limits

Summary

Infrared is highly operator dependent. Implementing the CorrectIR™ software will add benefits such as:

- Avoiding catastrophic failures by managing hot tubes before they reach a critical state

- Preventing unplanned outages and lost production time

- Optimizing online production, extending run times

- Assessing tube remaining life accurately

- Managing integrity proactively and making informed decisions concerning the scope, timing and coordination of maintenance

- Building an operating record that is based upon accurate and repeatable temperature measurements

With CorrectIR™ software, we have an infrared program that is based on scientific procedures that produce accurate measurements, repeatable data, and is less dependent upon the technician’s experience and background; thus shifting fired heater infrared application from art based to science based.

References

Peter, Saunders (2007). Radiation Thermometry: Fundamentals and Applications in the Petrochemical Industry. Bellingham, WA: SPIE-The International Society

for Optical Engineering

The work of Tim Hill, Process Engineering Optimization Manager at Quest Integrity, was instrumental in the development of this article.

Quest Integrity, a TEAM company, is a global leader in the development and delivery of asset integrity and reliability management services. The company’s integrated solutions consist of technology-enabled, advanced inspection and engineering assessment services and products that help organizations improve operational planning, increase profitability, and reduce operational safety risks. Quest Integrity is built on a foundation of leading edge science and technology that has innovated and influenced industry best practices since 1971.