Basic Inspection Tools Are Vital to Improve Your Condition Monitoring Process

Christer Idhammar, Founder

IDCON, Inc.

8801 Arco Corporate Drive – Suite 320

Raleigh, NC 27617

919-847-8764

www.idcon.com

Email:

![]()

There are four extremely important parts of basic inspections…I’ll give you a hint…use your senses! Sight, smell, hearing, and touch are essential when doing inspections, don’t worry we won’t make you taste anything.

The term Predictive Maintenance excludes these four senses, so I prefer to use the term Condition Monitoring, this includes all tasks you do to discover problems early—basic objective inspections, basic subjective inspections, vibration analysis, infrared measurements, wear particle analysis, ultrasonic material testing, acoustic emission testing and other methods.

In various studies we have found that most problems are, in fact, detected through basic inspections. Therefore, teaching operators and maintenance craftspeople basic inspection techniques and then deciding who is going to do the inspections in a route-based system is a very cost-effective way as a first step to reduce reactive maintenance. Believe it or not, these basic inspections are very important and often overlooked.

Some basic inspection tools include:

- Infrared Thermometers – for detection of misaligned couplings, leaking valves, and other components in hydraulic, and media systems

- Portable High Intensity Flashlights – improve visual inspections

- Tensiometer – to check and properly set tension of V-belts

- Inspection Mirrors and Fiber Optics – for areas difficult to reach

- Dye Penetrant – can be used to discover micro cracks in material

- Ultrasonic Leak Detectors – are especially useful to detect vacuum and other leaks

- Stroboscopes – enable inspections while equipment is in operation

- Ultrasonic Material Testing – discovers cracks or thinning in high-wear material

Condition Monitoring Tools Include:

Vibration analysis, which we all know is mostly used to analyze conditions of bearings and imbalances in rotating equipment, is part of predictive maintenance. So is wear-particle analysis, including ferrography and spectrometric oil analysis, acoustic emission used to discover early cracks in material, and infrared cameras used to visualize temperature patterns in equipment. This is an area where technology is developing very fast with many online systems installed on equipment for continuous monitoring and data collection.

The PM System

For any fixed-time PM, work orders can be used, but for any tasks to be done while operating (lubrication and basic inspections) a route-based system is more efficient. In setting up a new PM system it can be very useful to have some general guidelines to follow. As a principle you first decide what task must be done, then you decide who is going to do the task. Decide which categories of employees will be involved in executing the PM. I often recommend following categories by priority in this order: operators, maintenance craftspeople, in-house experts, and external experts.

Operators

Operators should be the first choice assuming the task is close to their work area and they are knowledgeable enough to safely complete the task. If not, consider training operators to do the task safely in a quick and efficient manner. If they can be trained in less than 30 minutes, you train them and then document the frequency and description of what needs to be done in the system.

If they cannot be trained quickly, the task will end up with the maintenance craftspeople.

Maintenance Craftspeople

Tasks that require more skill or are done with a longer frequency should be passed on to maintenance craftspeople.

In-house Expert

When vibration analyses, ultrasound, infrared thermography or other condition monitoring tools are needed, enlist in-house experts that are experienced with the equipment. If they are not aware of how to properly utilize the equipment then you may need to consider enlisting an external expert.

External Expert

As a last resort, turn to an external expert who can bring in expensive tools and skills that are not available at the organization for use. Consider if these tools or skills are necessary to acquire for your organization, if they are needed on a continual basis to ensure sufficient condition monitoring it may be worth investing in the training and technology.

Assess your current Predictive Maintenance System

Many existing predictive maintenance systems are many many years old, it’s important to remember to update and review the systems to ensure optimal performance. Technology for predictive maintenance has also improved and become much more affordable over the years, but the use of these technologies sometimes runs rampant without considering the existing PM tasks. It’s possible to reduce the PM work up to 30-50% if there is too much or convoluted PM in an organization, this results in higher quality PM.

Fixed-time Maintenance can be challenged and often switched to condition-based tasks on-the-run inspections. Many of these tasks can also be merged between mechanical, electrical, and operators.

Reliability Centered Maintenance

In addition to the required knowledge of equipment and components to set up an effective PM program, one needs to understand the basics of Reliability Centered Maintenance (RCM). Back in 1968, Dr. Horst Grothus and I did a training seminar together where he explained how failures are distributed in time as well as the different ways failures develop in breakdowns. Since then, I have used this as a guide when helping to set up and optimize PM systems.

Occasionally full blown RCM analyses are needed, but in most systems, critical failure symptoms and required PM tasks are quite obvious to those that are experienced. In my opinion full RCM analyses are most beneficial in the early design phase of systems and equipment.

Analyzing Failures

Many may suggest completing a Failure Mode and Effect Analysis (FMEA) on all components when you set up a PM system. It can be necessary during the design phase and on complex or unknown systems, but in most cases it is an over-complication. Instead of FMEA, I propose you think of what symptoms you might notice on a failing component and what method you can use for early detection.

Most common failures are random, others are regular or can be predicted. Regardless of experience or what statistics show, you cannot predict when random failure will occur.

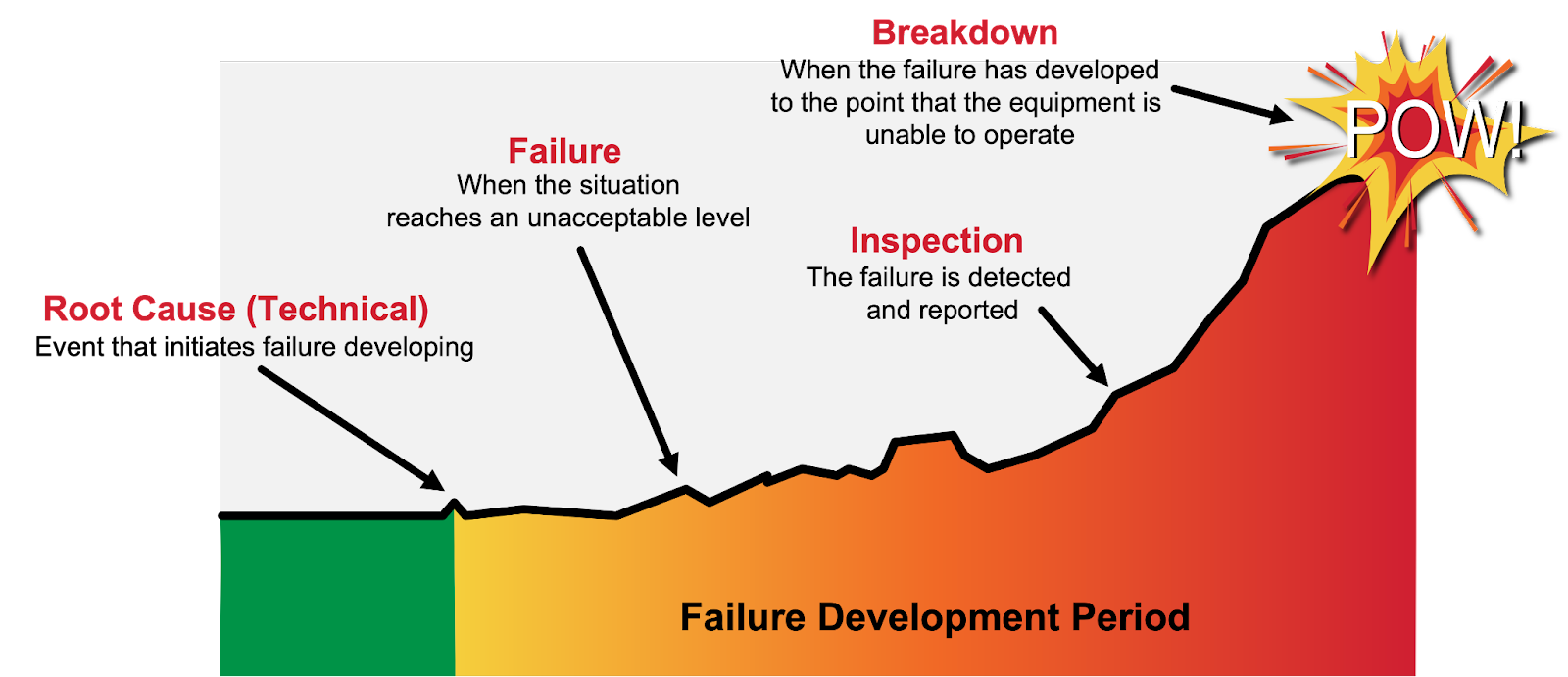

A drastic but clear example is how a valve’s time between failures can range from 1 to 12 years. If we combine random and regular with the estimated failure developing periods, which is time between failure and breakdown of component function, we can use this as a guideline to decide the best maintenance procedure: Operate to breakdown (OTB), Fixed Time Replacement or Overhaul, or Condition Based Maintenance (CBM).

If the failure is random with a short developing period and you cannot find any method to prolong this period, your choices are to apply redundancy of components or decide to run to breakdown and prepare in advance for corrective action, making sure you have needed spare parts and standard corrective job instructions.

For all scenarios that have a failure developing you can use condition monitoring, regardless of if they are distributed randomly or regularly in time.

Specific Scenarios

One scenario in which basic inspections yielded significant results involved a patent dispute. Years ago, in the early 1970’s I worked in a steel plant in Norway where we suggested marking some type of couplings with a line across the coupling halves. By using a stroboscope they could then inspect if the distance between the marks increased. If it did, it indicated wear of coupling bolts and, or, rubber bushings, and it was likely due to misalignment.

Nearly 20 years later, a manufacturer of these types of couplings contacted me because they were in a dispute with a competitor who had filed a patent to use this method on the same types of couplings. They had found documentation from a training I had completed in China, describing the very same method and wanted me to verify this.

Another scenario occurred many years ago in New Zealand while I was visiting all the sawmills owned by a single company. During training sessions at the facilities, I displayed a well-known method used to measure wear of chains. You measure the distance between five to ten chain links and as the distance increases you record the wear to a point where you have decided to replace the whole chain. Logs arriving at the mills were loaded onto a log deck with 4-6 parallel chains that lifted the logs into the sawmill. Their maintenance practice was to change the chains once a year in their low season, because “That’s what we’ve always done.”

Seven years later, at a conference in Auckland, I ran into one of the maintenance managers who took my advice to measure the chains and change them when needed. He had abandoned the old approach and by measuring the wear of the chains now replaced them every 18 months or so. Additionally, a salesman had offered them a chain for half the price, so they bought 3 to test, they ended up lasting for more than two years. So, “double the life at half the price!” was the result of using this very simple method. I have countless other examples of the results basic inspections can generate in addition to early detections of problems and increased time to plan and schedule work.

I am a big fan of case studies when we have large and/or complex issues to put theory into practical and tangible examples, when deciding which maintenance procedure is most cost effective. I find many PM programs contain too much Fixed Time Maintenance based on no more facts than “We’ve always done it this way.”

Christer Idhammar

Christer Idhammar started his career in operations and maintenance 1961. Shortly after, in 1985, he founded IDCON INC in Raleigh North Carolina, USA. Today he is a frequent keynote and presenter at conferences around the world. Several hundred successful companies around the world have engaged Mr. Idhammar in their reliability improvement initiatives.

Awards:

- He received the coveted EUROMAINTENANCE Incentive 2002 award during the biannual EUROMAINTENANCE 2002 conference in Helsinki in June 2002. Among 19 member European countries he was nominated and received the award from EFNMS – European Federation of National Maintenance Societies – for outstanding achievement and worldwide accomplishments in the field of reliability and maintenance.

- In 2008 he received the Salvetti Foundation Best Speaker all categories award among 154 speakers at Euromaintenance 2008 in Brussels, Belgium

- In 2013 he received the “Best presentation award” among 120 speakers at the Reliability 2.0 conference in Las Vegas.

Advertisement