Infrared Inspection of Load Break Elbows

Tip written by: Infraspection Institute

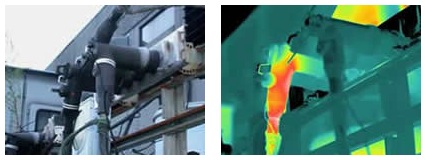

Load break elbows are a common feature on shielded cables. Thermography may be used to provide evidence of loose or deteriorated connections associated with these connectors.

Load break elbows are insulated plug-type terminals typically used to terminate shielded, underground cables. Load break elbows act as large power plugs for connecting cables to transformers, switching cabinets and bushings equipped with load break receptacle bushings.

Internal to load break elbows are several mechanical connections each of which is subject to deterioration over time. A typical elbow contains a crimp connection and a pin electrode that screws into the elbow. During normal operation, this pin electrode mates with a receptacle which also contains mechanical connections. Elbows and receptacles that have loose or deteriorated connections will operate at elevated temperatures and are readily detectable with a thermal imager.

~ Images courtesy Jim Lancaster

Normally, all electrical connections within an elbow are hidden from view due to the elbow’s molded rubber insulating body. Due to their high emittance, load break elbows are excellent candidates for infrared inspections. In fact, thermal imaging is one of the best ways to inspect these components for the integrity of their connections.

Since line-of-sight access to the electrical connections within load break elbows is not possible, temperatures at the point of origin are likely to be much hotter than observed temperature values on the exterior surface. Small Delta T’s observed on the surface of elbows can be indicative of a serious problem. Because of this, hot load break elbows should be investigated for cause as soon as possible and appropriate corrective measures taken.

Infrared inspection of power distribution systems is one of the many topics covered in all Infraspection Institute Level I training courses. For information on course locations and dates or our Distance Learning Courses, visit us online at www.infraspection.com or call us at 609-239-4788.

Advertisement