Infrared Inspections to Detect Process Piping Corrosion

Sponsored by:

Tip written by: Infraspection Institute

Infrared thermography offers good potential for detecting energy losses from process equipment and piping as well as some symptoms of pipe deterioration.

It is important to remember that thermography is a line-of-sight technology that detects thermal patterns and associated temperatures across the surface of an object.

Subsurface characteristics or defects cannot be detected by thermography unless they cause a temperature differential of at least 0.1 Celsius degrees across the surface of the object being inspected. Presently, interior corrosion detection is best detected with ultrasonic thickness testing; exterior corrosion may be detected by visual examination.

Thermography may prove useful if corrosion is being caused by water saturated insulation surrounding your process piping. If this is the case, water saturated insulation should show excess energy loss at the point where the water is entrapped. It will be necessary to visually inspect the pipe to confirm the actual condition of the pipe.

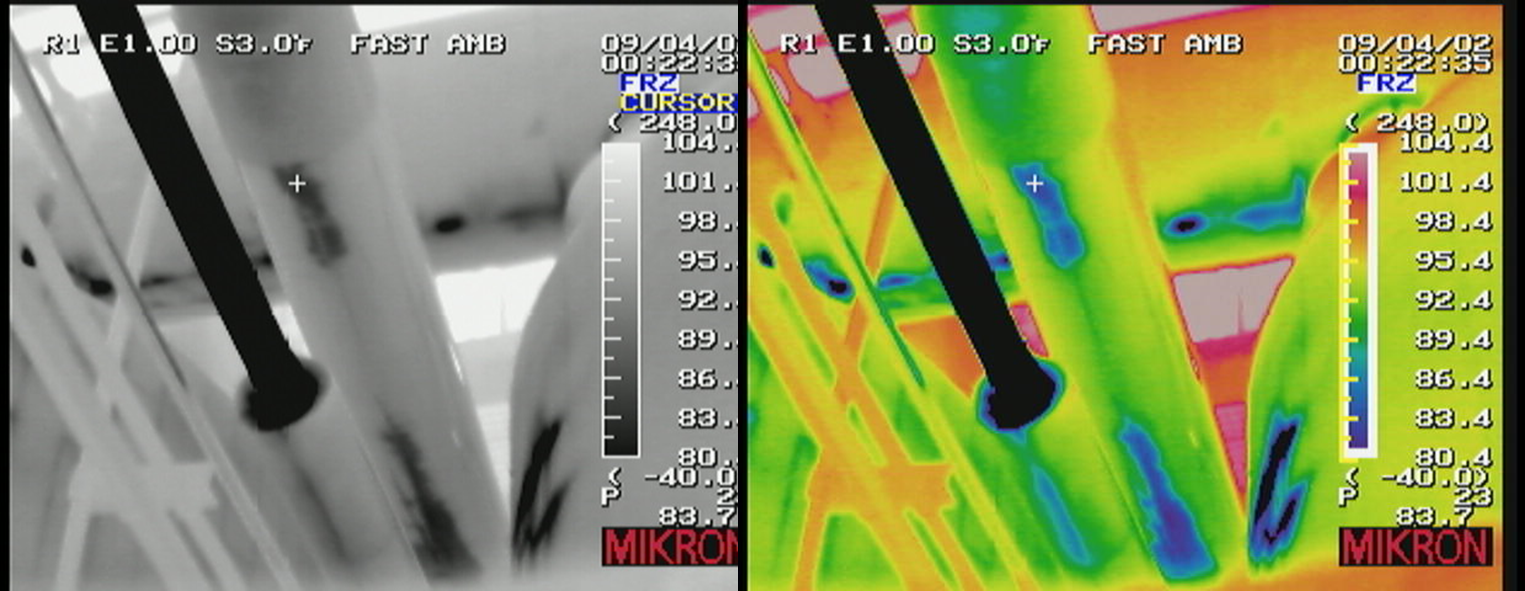

of chilled water lines. Cool areas due to wet insulation.

Note insulation on left pipe has been partially removed.

When performing thermal imaging, be aware that weather conditions such as solar gain, wind and atmospheric attenuation can adversely affect your results. Be certain that your imaging system is capable of detecting the anticipated defect by understanding how emissivity, spectral response and spot size will affect your inspection.

Infrared inspections of process equipment is one of the many topics covered in the Level I Infraspection Institute Certified Infrared Thermographer® training course. For information on thermographer training including course locations and dates, visit us online at www.infraspection.com or call us at 609-239-4788.

Advertisement