Using an IR Imager to Monitor Drywall Installation

Sponsored by:

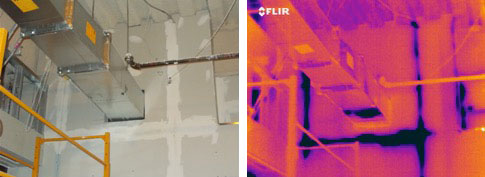

Finishing drywall is a routine part of commercial and residential construction. A thermal imager can be useful in helping to assess the drying process associated with newly-installed compound.

Drywall compound is a white powder consisting of gypsum dust mixed with water to form a mud with a consistency similar to cake frosting. Drywall compound is used with paper or fiber joint tape to seal joints between individual sheets of drywall and to cover fasteners in order to create a seamless finish on interior walls.

Drywall finishing often requires multiple coats of compound which are applied over several days to provide the desired surface quality. For best results, previously applied layers of compound should be thoroughly dry before successive coats are applied. Water evaporating from freshly applied compound causes pronounced cooling which can be readily detected with a thermal imager.

which is still drying. Areas with dried compound

provide no thermal contrast.

When using a thermal imager to inspect drywall compound, keep the following in mind:

- Choose an imager with sufficient thermal sensitivity and resolution

- Ensure that humidity and temperature levels are conducive to drying

- Always manually adjust imager’s level and gain controls for best thermal contrast

Lastly, missing or damaged insulation may create thermal anomalies across inspected walls; however, such thermal patterns will often be much larger than compounded areas.

Thermal imaging of buildings is one of the many topics covered in all Infraspection Institute Level I training courses. For course locations and dates, or to learn more about our Distance Learning program, call us at 609-239-4788 or visit online at Infraspection.com

Advertisement