John (Jack) N. Allinson, II BSc, AMS®

Level III Certified Infrared Thermographer

J.N. Allinson Associates, Inc.

222 University Blvd. North #2Jacksonville, FL 32211Ph: 904-721-2177www.allinson.com

Abstract

“Cold Molding” is a labor intensive process typically reserved for “Custom” boat builds. More often than not this process is used for Convertible Sportfish boats used for offshore fishing tournaments. A boat of this pedigree typically takes at least a year to complete and sells for over three million ($3,000,000.00) USD. The “Cold Molded” process uses strips of thin wood veneers and epoxy resin to create the complex shape of a boat hull.

The author is an Accredited Marine Surveyor (SAMS-AMS), Infraspection Institute Master Thermographer, co-author of the Standard for Infrared Inspection of Recreational Yachts & Small Craft Constructed of Fiberglass Reinforced Plastic and Composite Materials published in 2011 (aka “The Standard”) and has used Infrared Thermal Imaging in his Marine Surveying business since 2003.

This year’s presentation will demonstrate how the Standard was used to detect moisture intrusion in a Sixty-Six (66) foot custom convertible wooden cold molded sportfishing boat.

Introduction

When inspecting the “condition” of floating vessels, more often than not a proper analysis and interpretation of surface Infrared Thermal Image patterns compliments a visual inspection. We opine that if one follows the applicable sections of “The Standard” you will have an excellent source for basing defensible opinions of the condition of the vessel.

“The Standard” is a twenty (20) page document that was written and published in 2011 after eight (8) years of in the field experience with applying infrared thermal imaging to various requirements needed to document findings and produce a defensible report of a Marine Survey.

veneers and epoxy resin to create the complex shape of a boat hull.

in an indoor controlled environment.

flipped right side up using a travel lift.

trailer where it will be moved indoors for completion

Why a cold molded boat? The cold molding process produces a stronger and lighter hull versus traditional wooden planks affixed to frames. This translates into boats built with a smaller horsepower requirement for propulsion engines and excellent maneuverability.

More often than not predator game fish like billfish (marlin and sailfish) appear to respond best to the harmonic vibrations from a wooden hulled vessel. Game fish are sight predators and once they swim to investigate the source of the noise they respond to the various lures and teasers trailing in the boat’s wake.

bow thruster turns within a boat length

Application

repairs and refits on cold molded boats built by other manufacturers

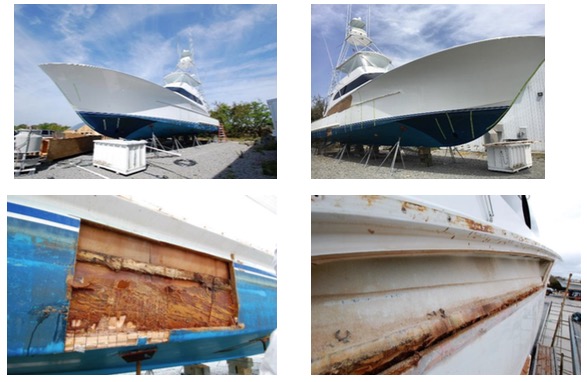

The subject boat below was completed in 2009 by a company that is no longer in business. During the haul out process, an aft STARBOARD section of the hull side gave way when stressed by the straps on the travel lift. A visual inspection of the damage concluded that the structural integrity of the hull had been compromised by wood decay from water intrusion.

Based on findings documented in the above photographs, J.N. Allinson Associates, Inc. was retained by Bayliss Boatworks to locate and map “suspect” areas of moisture intrusion into the cold molded material. Bayliss Boatworks used these findings as input for preparing their cost for repairs.

The scope of services was set to inspect the visible accessible surfaces of both PORT, STARBOARD, BOTTOM and STERN from the exterior of the boat.

It is important to note that Section 13.4 of “The Standard” states that accurate interpretation of infrared data requires verification by:

- other NDT techniques

- and Destructive Testing

Summary

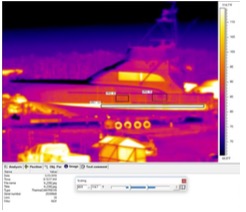

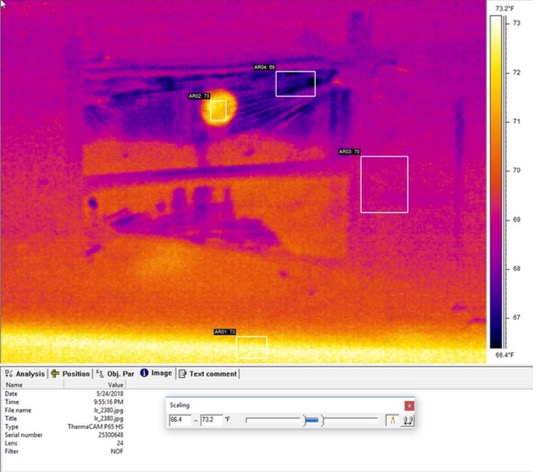

Visual inspections, moisture meter readings, percussion soundings and computer software analysis of the infrared thermal images revealed moisture intrusion on the PORT, STERN, and STARBOARD hull sides and isolated areas on the hull bottom of the boat. Select areas of Destructive Testing on the PORT side of the boat confirmed moisture intrusion.

Conclusion

Hull condition

Based on what is known regarding:

- the boat construction,

- moisture meter readings both within and outside of the documented margins of the thermal pattern anomalies (Figures 2, 3, 5, and 6),

- select destructive testing followed by installation of a moisture barrier and evidence of water condensation on the interior of the moisture barrier and taking into consideration (Figures 7-11),

- the general morphology of the thermal anomalies,

- the absence of visual exterior catastrophic damage in the areas showing thermal anomalies and wet moisture meter readings,

- and the discoloration of wood surfaces in exposed interstitial areas of thewooden hull construction

it is the opinion of J.N. Allinson Associates, Inc. that sections of the wood in the PORT and STARBOARD hull sides were “wet” and will decay and deteriorate when exposed to environmental conditions that support wood destroying organisms.

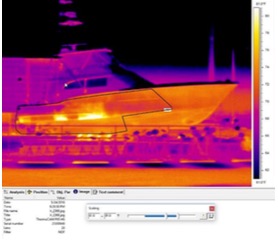

The boat was stored in the open on a hydraulic trailer. In accordance to criteria as set forth in “The Standard” the boat was oriented with the STERN facing North and the BOW facing South (see Exhibit I). This North/South orientation is preferred when doing infrared studies that rely upon solar insolation over a diurnal period to evenly warm and cool the boat.

Environmental conditions during the infrared inspection were acceptable as there was

- no cloud cover

- full exposure to solar insolation on both PORT and STARBOARD sides of the boat

- average wind speed of 6 mph or less

- no precipitation

- and at least a 10°F change in air temperature during the diurnal period

Given the documented environmental conditions, the positioning and orientation of the boat, J.N. Allinson Associates, Inc. is of the opinion that the interpretation of the thermal patterns from the infrared thermal images obtained during the study period are valid.

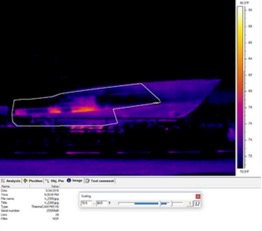

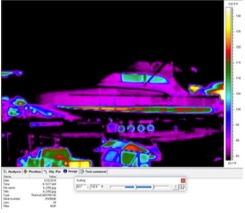

Infrared Thermal Images

border observed in the evening

adjusted, color of border changed to white.

Temperature within the bottom border is much hotter

than bordered areas of the hull above.

span adjusted and different color palette.

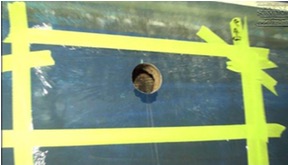

Destructive Testing

confirm where to cut coupon in hull.

with a hole saw.

document any moisture leaving the hull cavity.

moisture accumulated behind clear plastic barrier.

Materials

Radiometric imaging equipment

Radiometric imaging software used in image analysis

- ThermaCAM™ Researcher Pro 2.8

- FLIR Tools+ Version 6.3.17227.1001

Video and Still images

- SONY HI DEF digital Video Camera Model HDR-XR500V s/n 672679

- GoPro HERO 3+ Black Edition Percussion Sounding

- hammer with hard plastic face

References

Standard for Infrared Inspection of Recreational Yachts & Small Craft Constructed of Fiberglass Reinforced Plastic and Composite Materials.

2011 Edition Infraspection Institute

www.infraspection.com

Interesting reads:

https://www.powerandmotoryacht.com/boats/cold-molded-carolina-boats

https://www.powerandmotoryacht.com/boats/designing-future

https://www.baylissboatworks.com/

Interesting videos:

https://vimeo.com/279258211

https://vimeo.com/293560633?from=outro-embed

https://vimeo.com/256092657

About the Author

The author is an Accredited Marine Surveyor (SAMS-AMS), Infraspection Institute Master Thermographer, co-author of the Standard for Infrared Inspection of Recreational Yachts & Small Craft Constructed of Fiberglass Reinforced Plastic and Composite Materials published in 2011 (aka “The Standard”) and has used Infrared Thermal Imaging in his Marine Surveying business since 2003.