Advanced Techniques in IR Thermography as a Tool for the Pest Management Professional

Jon L. Grossman

Hi-Tech Inspection Services, Inc.

7520 NW 54th Street

Miami, FL 33166

Ph: 305-639-1820 / Fax: 305-639-1928

Abstract

Within the past five years, the Pest Management industry has become aware that IR thermography can aid in the detection of pest infestations and locate other conditions that are within the purview of the industry. This paper will review the applications that can be utilized by the pest management professional and discuss the advanced techniques that may be required in conjunction with thermal imaging to locate insect and other pest infestations, moisture within structures, the verification of data and the special challenges associated with the inspection process.

Recent History

As you might have learned from my presentation last year, the use of IR thermography as a tool in Pest management is a fairly recent phenomenon. About six or seven years ago, a gentlemen by the name of Jack Leonard, who was employed by the New Orleans Termite and Pest Control Board (NOMTCB) asked an IR camera vendor at a trade show if he could find termites with the IR camera. The vendor was Bob Melia, who was a prime mover in the US Coast Guard’s employment of thermal imaging cameras. And so the saga began. They began testing cameras and various lenses and soon the duo noticed that when they imaged the interior of buildings in New Orleans and found anomalous cooling, there was a correlation between the presence of moisture and the possible presence of insect pests – in their case Formosan termites. They also discovered that when they noted anomalies on wall or wood structures, in many cases, the anomalies represented subsurface defects that had a high correlation with damage that had been or was being done within the wood structures, again by termites. In both cases the anomalies were not visible to the naked eye.

With positive result after positive result, the use of the IR thermal imaging camera began and the use of an IR camera became a key tool in Operation Full Stop (1998 to present), a USDA and US Congress mandated project aimed at containing and treating the Formosan Termite infestation in the Historic New Orleans French Quarter. Today,

an IR thermal imaging camera is a standard tool to be used whenever the NOMTCB does termite pest inspections in New Orleans. Though Jack Leonard has since retired, he perhaps has more experience and was the pioneer in the use of IR cameras in termite detection.

In the last two or three years, additional work with infrared imaging has led to the IR camera being used not just for termite detection but also for a host of other insect pest problems.

Modern Challenges – Detection

In pest control, the process begins with detection. You may know that the insect pests are there  because of some physical evidence, but where, and to what extent is the infestation, are the questions. As mentioned last year, modern construction materials as well as better construction techniques have provided new forms of harborage and new food sources for the insect pests. Everyone knows that the use of slab construction has made the home stronger and more durable, but on the other hand it has also helped in hiding the entry points that the pests use. Plasterboard or gypsum board has replaced lathe and plaster providing uniform strength and ease of installation. Unfortunately, it offers a great food source for the cellulose eaters such as termites. A good carpenter will, to the naked eye, create tight joints and flush fittings; however, hidden behind that paint and stucco are tiny openings perhaps only 1/16” in diameter. These small openings can permit the entry of tiny termite alates that can mature into a termite queen capable of fostering millions of other termites or permit the entry of other insect pests such as carpenter ants. Some pests, such as carpenter bees, need no man-made or openings created by shrinkage. They create their own entryway by chewing their way into a structure.

because of some physical evidence, but where, and to what extent is the infestation, are the questions. As mentioned last year, modern construction materials as well as better construction techniques have provided new forms of harborage and new food sources for the insect pests. Everyone knows that the use of slab construction has made the home stronger and more durable, but on the other hand it has also helped in hiding the entry points that the pests use. Plasterboard or gypsum board has replaced lathe and plaster providing uniform strength and ease of installation. Unfortunately, it offers a great food source for the cellulose eaters such as termites. A good carpenter will, to the naked eye, create tight joints and flush fittings; however, hidden behind that paint and stucco are tiny openings perhaps only 1/16” in diameter. These small openings can permit the entry of tiny termite alates that can mature into a termite queen capable of fostering millions of other termites or permit the entry of other insect pests such as carpenter ants. Some pests, such as carpenter bees, need no man-made or openings created by shrinkage. They create their own entryway by chewing their way into a structure.

The insect pests live virtually hidden from view and flourish, happily munching away, almost always only to be discovered, when they leave a sign of their presence. Perhaps that sign is in the form of fecal droppings, called frass, or perhaps it is only found when the bubbling paint becomes obvious or even more obvious when the floor or ceiling collapses. These types of occurrences are obviously too late to prevent the damage, but provide sufficient evidence for immediate pest control action and possible lawsuits.

Why Thermal Imaging?

In pest control, the keyword is DETECTION. If a pest management professional cannot detect where the pests are and the extent of any particular pest problem, he can never consistently excel in pest control work. Can IR thermography help in the process? Does our experience as thermographers help us or hinder us when it comes to using thermal imaging in the pest control industry? What do we need to know and do as thermographers to participate in this new industry? These are the questions of the day.

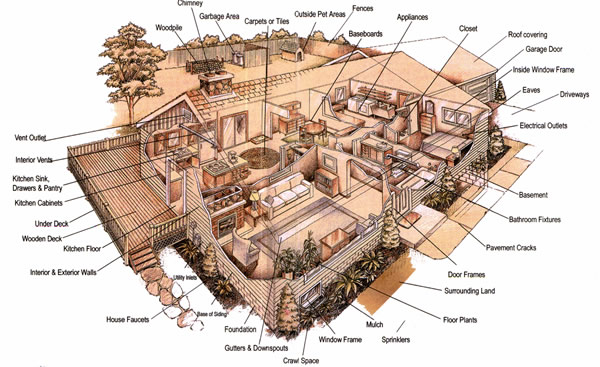

Elements of a Pest Control Inspection

Pest control inspections can be a tedious process. If one thinks about the work that needs to be performed, time is money, and the longer an inspection takes, the higher the cost to the inspector. Ideally, any inspector would like to do a drive by inspection. You ask, what’s a drive by inspection. It’s when you leave the motor running and do a complete house inspection in 15 minutes and, of course, sign off on it. Very few people realize the extent of or the number of elements that are required in a complete pest inspection. Even fewer inspectors have priced their inspections at rates that permit them to make a living. The following image points out most, but not all, of the elements that must be taken into consideration in a pest inspection.

You will note that there are elements both inside and outside. One must be careful. A complete inspection will cover scanning almost every inch of the premises. With the increase in liability factors and the fact that we are becoming a more litigious society, many pest inspectors and even the public are beginning to realize that a more professional inspection needs to be performed and this cannot be done for free nor for an immodest sum of money. A thorough inspection, including validation, will take at least one to two hours for a small to medium sized house for an experienced inspector/thermographer.

In pest management, the IR camera can best be classified as a gross overview inspection tool. Thermal imaging permits a skilled operator to rapidly inspect a job site. Properly used as the initial inspection tool, thermal images can significantly assist in narrowing down those areas that require special attention.

What are we looking for and how should we begin?

As thermographers, we are primarily used to looking for anomalous differentials in heating or cooling signatures. However, use of the IR camera as a tool in the pest control industry is very different from what we are normally used to. If we are using thermal imaging for the inspection of electrical circuitry, the inspection of motors or for the inspection of operating machinery, we are usually looking at thermal emissions of a higher temperature and the anomalies are usually readily apparent, especially when radiometric readings are available.

As thermographers, we are primarily used to looking for anomalous differentials in heating or cooling signatures. However, use of the IR camera as a tool in the pest control industry is very different from what we are normally used to. If we are using thermal imaging for the inspection of electrical circuitry, the inspection of motors or for the inspection of operating machinery, we are usually looking at thermal emissions of a higher temperature and the anomalies are usually readily apparent, especially when radiometric readings are available.

Occasionally, some of the normal discoveries we thermographers find in residential or commercial establishments comprise major elements in diagnosing pest control issues. For instance, the discovery of a roof leak can become the source of moisture that is supporting a colony of insect pests or expose a mold problem.

As you have heard before, a typical example of the difficulties that might be easily overlooked is a termite mud tube. A termite mud tube might be less than 1/4 of an inch wide and may be on the inside of a gypsum wall, hidden in a small crack in brickwork, or located inside a concrete block. In addition, an active termite mud tube might contain less than 20% in moisture while an abandoned mud tube, that may indicate the presence of termites, may contain very little moisture. Obviously, difficult to see and easily overlooked. When it comes to pest control, a miss can result in hundreds, thousands or tens of thousands of dollars worth of damage. On the other hand, locating an infestation of termites or carpenter ants in its early stages might save thousands or even tens of thousands of dollars worth of damage, as many a lawsuit will attest. In addition, locating the toxic black and other types of molds may forestall sickness and even death.

Understanding and having knowledge of the primary factors that are associated with some insect pest problems is an absolute requirement for any thermographer attempting to do pest control work. A pest control thermographer must be aware that in a vast majority of the cases, the anomalies may be very, very small and may be easily overlooked. Inspections in pest control consists, almost entirely, of low or near ambient temperature emissions with sometimes very subtle changes in imagery. It is not only the skilled eye of the thermographer, but also an understanding of what the attendant pest situation might be, that aides the thermographer in making proper interpretations and analysis of the thermal imagery. Having the knowledge and the understanding of other factors such as seasonal and regional pest variations, the types of insect pests known to inhabit the region, the typical structure of their nesting places and the food they require, will also help in the proper interpretation and analysis of the imagery.

So what are we looking for?

Here are three sets of images, what do they represent?

There are two (2) basic elements a trained inspector will be looking for: 1) areas exhibiting anomalous elements that could be associated with the presence of moisture or hot spots, and 2) the presence of subsurface defects. These elements, once found, comprise the basis for perhaps a dozen possible pest problem diagnoses.

As mentioned in previous presentations, one of the major signs of a possible pest infestation is moisture. Moisture is a critical element needed to support the life of the insect pest and is either absorbed or ingested through the foods they eat. But not all insect pest infestations have thermally visible moisture levels where they are found. Dry wood termites gain moisture through the wood they eat and their colonies may only exhibit a tiny increase in moisture over the surrounding wood, perhaps 2 to 5% above the ambient moisture levels of their habitat. In other instances, especially where there is an above ground pest colony, significantly more moisture may be present. Without moisture, insect pests will die. Therefore, one of the primary objectives in any thermal inspection process is to locate evidence of anomalous cooling that, in many but not all cases, indicates the presence of latent moisture. If you were a pest control specialist you would know that moisture is a necessary element not only in the existence of most insect pests but also in the existence of all fungi (mold).

For those thermographers who may not realize it, in many states, mold falls within the legal definition of a wood destroying organism and you may be required to obtain a state license to work with mold. In almost all states, pest control is a regulated industry and is also licensed.

The last element we are looking for is subsurface defects. Subsurface defects are possible evidence that a pest problem currently exists or might have existed in the past. In all cases, where there is evidence of anomalous cooling, heating or subsurface defects, as far pest control is concerned, these areas require immediate attention to determine if they are relevant or not.

The pest thermographer’s nightmare

So you can begin to see what the pest thermographer faces. Now let us begin to focus on what nightmares face the pest thermographer. Near ambient temperatures, then there’s moisture but no pests. In addition to hundreds of areas that need to be studied, the thermographer is faced with evidence of insect pests, but there’s no evidence of anomalous cooling or hot spots on the thermal images. Lots of maybes and the site conditions can make it worse. Perfect conditions would enable us to have our preferred delta of 15 to 20 degrees F. Most of the time, when inspecting residences, we find either fairly good or poor conditions depending upon the region of the country we are in or if the premises has air conditioning. In the summer, it may be 85° or 90°F or higher outside and if we are lucky and if there is A/C, it is probably between 75°F and 80°F inside. Time to improvise. Time to take an active role in the thermal pest inspection process.

Active Techniques that Can be Used with IR Pest Inspections

As in most thermal imaging inspections, the IR camera is but one tool in the inspection process and in many instances, active thermography is required to truly locate and diagnose the problem.

As for camera settings, the writer prefers a grayscale setting. The reason being is the human eye has a greater ability to differentiate between 256 shades of gray than differentiating in shades of color. Many color images have a tendency to overpower even the most minute detail we are seeking. Generally, radiometric readings will not be of much help. If you have a radiometric camera, you can narrow the temperature range to plus and minus 15° of ambient. Scan areas looking for even the slightest differentials. By differential, it means not only thermal anomalies but also subsurface differentials and even what appear to be tiny spots, especially when there is other evidence of the presence of insect pests. A spot may lead you to the pot of gold. An example of other evidence might be termite frass (termite excrement) which, if you are knowledgeable, will enable you to differentiate between different species such as subterranean or dry wood termites.

Create a Delta

The simplest active technique is to change the thermal conditions inside the premises. Crank up the AC or turn up the heat. Attempt to bring the general conditions closer to the delta needed. Again, most of our findings will be near ambient temperature but the need for a good delta will help increase the possibility of locating those anomalous indications or subsurface defects.

Even though you are able to create the delta in the general conditions, you may be required to utilize other active techniques once suspicious areas are located.

The following are pictorials of common tools that can be utilized in active pest thermography.

Cooling techniques

Active cooling can be accomplished by injecting air or other gasses that have been compressed into holes or crevices. As the air is being injected, it will expand from its compressed state and will cause a cooling effect of the surrounding materials it contacts, thus creating anomalous cooling. The effects will be seen anywhere from milliseconds to a few seconds depending upon the depth and volume of the internal structure as well as the depth from the surface and the insulating abilities of the material. Metal, for instance, will react more quickly than wood.

Remember, once an anomalous event is located, a diagnosis will have to be made as to whether the anomaly seen is a result of subsurface defects or other elements such as differentials in emissivity or simply surface blemishes or markings.

Compressed Air Tools

Heating techniques

Active heating can be used to identify areas with subsurface defects. This can be accomplished by actively heating the area you are examining with lamps or forced air. As the surface is cooling, the areas with anomalous cooling behavior will begin to show. The effects will be seen anywhere from a few milliseconds to a few seconds depending upon the depth and volume of the internal cavity structure as well as the depth from the surface and the insulating abilities of the material. Metal, for instance, will react more quickly than wood.

Tools to Assist in Diagnosis and Validation

Now that we have learned some of the tools that can be utilized in active thermography to help locate and enhance the problem areas, we can address what tools can be utilized to assist in the diagnosis of an anomaly and how to validate the diagnosis.

While the thermographer’s initial impression of any anomaly may be correct, that impression for pest control purposes may only be partially correct. To make that diagnosis 100% correct, in almost all but a few cases, an additional tool or series of tools must be employed to validate the findings and to make the correct diagnosis.

The following is a brief list and description of some equipment that can be used singly or in combination to provide and verify impressions and to assist in making a diagnosis:

Moisture Meters

Locating the presence of latent moisture is not enough. A pest thermographer must then confirm the presence and level of moisture. Usually, a moisture meter will be employed.

Microwave Detection Equipment

Microwave Detection Equipment

Termatrac® is a hand-held portable detection device using patented microwave technology. Termatrac® can detect insects and other pests in unseen areas such as wall voids, cracks, crevices, air pockets, construction flaws, beneath floors, and in ceilings, etc. Termatrac® will detect activity through a variety of materials such as brick, wood, stucco, concrete block, ceramic tile, marble, terracotta tile, mica, plastic veneers, vinyl and many other materials. Termatrac® is non-invasive and non-destructive, thereby avoiding damage to a client’s property.

Acoustic Emissions Detection Equipment

AED 2000L is a portable hand-held instrument that is the most advanced and sensitive acoustic detection system for locating termites and hidden insect pest infestations in wooden structures, trees, plants and soil. The AED, a product of several years collaboration with the USDA Agricultural Research Service, literally permits the user to listen to the insect pests eating their way though wood or even, in some cases, walking.

Structural Test Equipment

Structural Test Equipment

The Resistograph is an instrument that is utilized to measure the structural integrity of wood structures. Utilizing a very fine drill, the Resistograph, as the drill penetrates the wood structure at a predetermined rate and torque, measures the resistance and changes in torque to provide a printable data record of the probing actions. If there is an insect pest gallery present or if there is wood decay, the Resistograph will provide the data necessary to make a structural analysis of the situation.

Boroscopes and Video Imaging

Boroscopes and Video Imaging  Boroscopes

Boroscopes

Boroscopes, both manual and video imaging, can provide crucial confirmation of the presence of insect pest infestations. Inserted through a tiny hole, the boroscope probe can be manipulated to the suspected area of infestation where visual confirmation can be obtained. Either video or a digital imaging camera can be utilized to record the findings.

Video Imaging Boroscope (Above Left);

Simple Srticulating Boroscope ( Right).

Findings, Interpretations, Diagnoses and Recommendations

The interpretation and diagnosis of the findings, whether they are anomalous cooling or hot spots, subsurface defects or simply areas of concern, is perhaps the most important. These findings are not something that a thermographer will generally take back to his office for interpretation. The norm in pest control work is that the interpretation and the diagnosis go hand-in-hand and need to be accomplished in the field, on the job site. Once that is accomplished, the results need to be validated.

Once a preliminary diagnosis is made, the interpretation and recommendations are the critical factors that need to be validated. That process will either confirm or alter the initial diagnosis. To provide a better understanding of what steps or procedures might be followed, the following are some examples, as well as the recommended use of additional tools that might be utilized in the diagnosis and validation process:

Example #1 – Anomalous cooling in ceiling and adjacent wall

Preliminary – moisture (source unknown)

Preliminary – moisture (source unknown)

Validation – use moisture meter

Confirmed – moisture – level in red zone

Suspicion – insect pests or mold

Validation – use Termatrac

Result – no activity

Validation – use boroscope

Result – Mold

Search for source of moisture

Diagnosis – Mold caused by roof leak

Example # 2 – Remember Above, Question #1

Anomalous heating in floor area

Preliminary – wiring problem

Validation – no apparent electrical conduit or circuitry

Validation – use Termatrac

Result – meter indicated activity

Validation – use AED

Result – hear active termites

Diagnosis – Termites – above ground colony

Additional tools & activities – boroscope, search crawl space or basement, track back to entry point

Courtesy – Jack Leonard, New Orleans.

Example # 3 – Subsurface defect in side of door

Example # 3 – Subsurface defect in side of door

Preliminary – moisture or subsurface defect

Validation – moisture meter

Results – slightly above ambient

Validation – Termatrac

Results – activity

Diagnosis – termites

Active steps – inject cool air

Diagnosis – Dry wood termites, gallery lit up

Additional tools & activities – use Resistograph

The above has given you some idea of what is meant by validation of your findings. Much like doing a roof inspection, validation by sampling or use of additional tools from your tool bag is required in many cases. In pest work, validation is necessary. Photos and documentation are necessary.

The following are some images that will demonstrate some additional enhancements using active thermography.

Situation:

Subsurface defects seen

Other visual evidence of damage

No evidence of anomalous cooling

Frass evident

Tiny holes seen, possibly kick holes

Proactive possible techniques:

Inject cool or hot air into kick holes

Use flash lamp

Use hot air on surface

Use Termatrac

Use AED

Objective:

To confirm presence of dry wood gallery

The presence of warmer appearing areas within wall structures may be somewhat confusing. The warmer areas in this image are due to displaced insulation. They are actually caused by mice tunneling within the walls, displacing the insulation in areas surrounding an air duct inside the walls of a child’s playroom. These tracks would go undetected in an ordinary visual inspection.

The presence of warmer appearing areas within wall structures may be somewhat confusing. The warmer areas in this image are due to displaced insulation. They are actually caused by mice tunneling within the walls, displacing the insulation in areas surrounding an air duct inside the walls of a child’s playroom. These tracks would go undetected in an ordinary visual inspection.

Home Safe Inspections took this image.

What is it? From Above.

What is it? From Above.

Additional Uses of the Thermal Imager in Pest Management

From time to time, during the process of performing a pest inspection, the pest thermographer will undoubtedly encounter many different situations that can be of benefit to his client. As seen from the images above, rodents and other small animals that nest within walls, crawl spaces or in attics are an additional problem. The thermal imager will be of great assistance in locating these warm blooded critters who make nests in the attic, in the crawl spaces or inside the walls. Care needs to be taken when active nests are located. A startled rodent can cause serious problems for a thermographer who has a fear of rodents or who is suddenly surprised. Safety of balance, especially when in tight crawl spaces, in attics or on ladders is a must.

In addition, occasionally, there may be a strong odor coming from the inside walls, attics or crawl spaces. Don’t be surprised to find dead animals with the use of your thermal imager. Simply wear appropriate clothing and protective gear when removing the carcass.

Since part of the pest detection inspection process includes scanning all areas of the house, be aware that insect pest nests have been found inside such things as electrical panels and plumbing areas.

It will not be unusual to locate electrical problems like undersized wires, defective circuit breakers or loose connections or leaks not only from plumbing problems but also from defects in the roofing or construction.

Additionally, while performing the pest inspection, the thermographer will encounter the usual building envelope problems, missing, poor or no insulation, outside air intrusion, duct leaks, heat and cold loss and the other usual thermal imaging discoveries that are ingredients in residential or commercial thermal inspections. These findings can be incorporated into a single inspection or can be separated into a subsequent inspection, thus providing the thermographer with a second earnings source from another inspection.

In addition, since the use of thermal imaging will permit the ability to see the thermal patterns caused by hidden wall structures, the use of the imager to locate appropriate locations for chemical treatments or for the remediation of a pest problem is an essential tool. As can be seen in the image at the right, assume that an infestation has been found in a cathedral ceiling, the uses of a

thermal imager will permit the placing of the required treatment chemicals in the required locations. If a section is missed, it may provide harborage for the insect pest to survive.

Additionally, as part of any pest treatment program, two factors for a successful treatment are necessary. One, if there was a contributing factor, such as moisture, providing conducive conditions, the contributing factor must be removed. Use of the thermal imager will confirm that the moisture issue has been resolved.

Secondly, once treatment has been affected, it is customary and of good practice to confirm the effectiveness of that treatment. The thermal imager can play a role in that confirmation process, but again, is but one of the tools to be utilized in the process. This post-treatment inspection becomes a second and perhaps a third inspection.

Conclusions and Risk Factors

Use of the thermal imaging camera can, in many cases, be the first tool used to locate insect pest problems. Pest control thermography is a complex job requiring not only thermographic skills but also an intimate knowledge of insect pests, their habitat and the difficult task of separating impressions from fact. Only with a well-rounded knowledge of the subject can a proper inspection and image interpretation be accomplished. If you don’t have the pest management skill, team up with a pest management professional who has many years of field experience.

A skilled inspector will sometimes need to exclude or factor out more things than he factors in. Benign sources, such as IR emissivity variations, reflections, surface markings or blemishes of the surface being observed serve to complicate the imagery. The task is sometimes confusing. Insect pests like dry wood termites, wood borers, carpenter ants and certain bees, all are wood destroying insects that eat or excavate the softer part of the wood or cellulose structure, sometimes leaving a perfectly good looking exterior shell. Sometimes, the structural integrity of the structure has been compromised without any visual signs. Mold is a whole other issue and raises fears even among the highly educated.

Pest management thermography should really be classified as a specialty. It is easier to become a pest thermographer if you have a pest management background and a significant amount of field experience. It is much more difficult to do it in reverse.

The liability factors can be quite severe and one must make sure that one is properly insured.

Historical sites pose additional issues. In many instances, the use of additional tools to validate findings may pose problems. Make sure that the inspection do’s and don’ts have been spelled out.

In recent times, there have been some unique inspections utilizing thermal imaging. Subjects that have never been inspected using thermal imaging before require extreme caution due to possibly unexpected results. It’s one thing to do inspections on subjects that have been inspected before. It’s quite another to inspect a subject or item that has never been inspected before. The possible results are unknown and even if a thermographer feels he might have enough experience to handle the job, it may be safer, cheaper and much less of a liability to pass on the inspection or refer it to someone else who might be more capable of performing the job.

The pest management business is notoriously cheap. The pest management professional will do inspections for next to nothing to get the treatment job. As a professional thermographer, your equipment is very costly and your time is valuable. You are, after all, a professional and need to be properly compensated for your expertise. Converting the pest management profession to that point of view is a challenge. If you can get beyond that, being a pest thermographer has its rewards. There is no doubt that finding insect pest problems when others have failed is a real pat on the back. Professionally approached, the pest thermography business can become an annual inspection and if problems are found, second and third inspections may be called for.

A final caution. It is additionally important to know your equipment and its capabilities. Sometimes one must realize that you may not have the right imager for the job. Also, you may have the right type of imager but perhaps the sensitivity of your imager itself makes it the wrong imager for the job. Additionally, it is the author’s opinion that color viewfinder images have a tendency to wash out the tonal contrasts needed to detect many of the anomalies associated with pest problems.

Pest control thermography is not a walk in the park.

Advertisement