Ed Kochanek

Eastern Region Sales Director

FLIR Systems, Inc.

22 Overlook DriveWoolwich, NJ 08085Ph: 866-379-4022 www.flir.comAbstract

Infrared detectors are solid state devices that are the heart of a thermal imager. It is the detector which converts heat energy into an electric signal which is then converted to images and temperature data. Recent innovations in infrared detector design have led to reductions in both cost and size. This has allowed manufacturers to design amazing new thermal imagers. This article will discuss how we may be in the golden age of thermal imaging and will discuss some of the new innovations and how infrared is slowly becoming our sixth sense.

Introduction

During the first 30 years of thermal imaging, the cost of an infrared camera was very expensive. Typical cameras sold for over $50,000. Most of the cost was associated with detector manufacturing and the optics. Also contributing to the high cost was a limited market. Thermal cameras were usually sold to utility companies, infrared consultants, and heavy industries.

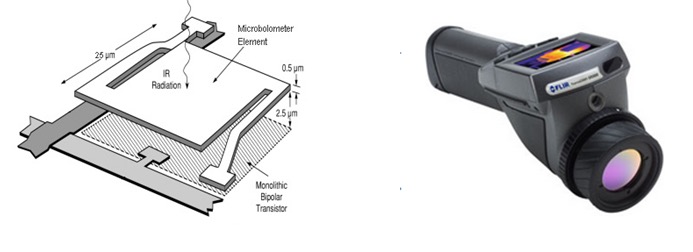

As time went on, new technologies emerged that reduced cost. One such innovation was the microbolometer detector that is found on most of the cameras manufactured today. Since the microbolometer did not need active cooling, manufacturers were able to use less expensive materials to create the cameras. This also allowed for smaller packaging and designs.

FLIR E2

Starting the industry down the path to more affordable cameras, was the introduction of the FLIR E2 camera in September of 2002. It was small, lightweight, and easy to use. It had a 160×120 focal plane array (19,200 pixels), which was about a quarter the size of the standard thermal camera. The E2 had onboard storage using a USB cable to transfer images. The batteries lasted over 2 hours making it a very portable system and a convenient instrument to use. The most amazing part of this camera was its cost. It was half the price of current technology. It sold for only $27,950. This was a huge drop in price and the industry reacted very positively toward it. Eventually, this camera’s price would drop down to below $15,000, which increased the demand for the technology. This was the first camera that small to mid-sized manufacturing companies could own. It was at this point that the industry changed. No longer was thermal imaging just for the high-end utility customer and large manufacturing plant. It was now practical for any level of customer to consider owning.

The E2 also paved the way for other camera manufacturers to introduce their own low cost cameras. As more manufacturers came on, new industries were discovering the benefits of the technology. The water restoration sector took quickly to the advantages it offered, purchasing as many cameras as they could afford. Infrared was proven to find water quickly and easily. It also allowed them to document their findings for reporting to insurance companies. It also reduced their risk for un-dried areas to grow mold.

The next industry to benefit from low cost thermal imaging was the weatherization industry. As the cost of energy skyrocketed, it became very affordable for companies in this industry to invest in thermal imaging to locate excessive heat transfer in customers’ homes. Also, all types of Government Agencies used funds to help spur the use of thermal cameras for this purpose.

Lepton: A Game Changer

Earlier this year FLIR introduced a new low cost detector called Lepton. This represents the first major design change since the microbolometer was introduced in the mid 1990’s.

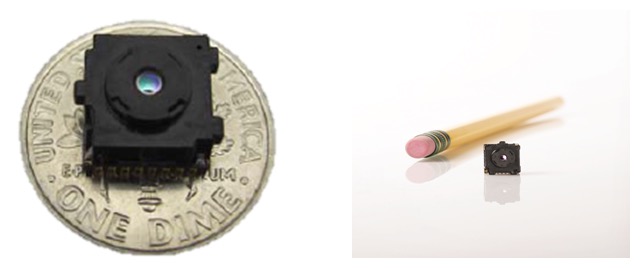

Lepton utilizes innovative technology, high volume manufacturing techniques, and commercial scale to deliver a price point that is an order of magnitude below current thermal camera cores. Similar in size, weight, and power consumption to a conventional CMOS cell phone camera module, Lepton is the world’s smallest microbolometer-based thermal imaging camera core currently available.

Lepton utilizes multiple proprietary technologies, including wafer level detector packaging, wafer level micro-optics, and a custom integrated circuit that supports all camera functions on a single integrated low-power chip.

The new Lepton core facilitates accurate temperature measurement and is fully compatible with FLIR’s patented Multi-Spectral Dynamic Imaging technology, or MSX®, which significantly enhances the thermal image fidelity with data from a visible-light sensor.

Lepton is a groundbreaker for thermal imaging detector manufacturing because it changes the dynamic of what we now consider a thermal imager. Until now, the thermal imager was built as a stand-alone device. Since Lepton is so small, it can be placed into existing devices. So, now every tool or instrument we use can house a tiny thermal camera.

What job would be made easier if there was a thermal imager attached? What tools do we use to find moisture? What tools do we use to measure volts or amps? It’s easy to dream that these tools and our jobs would benefit from having a thermal imager built in.

FLIR One

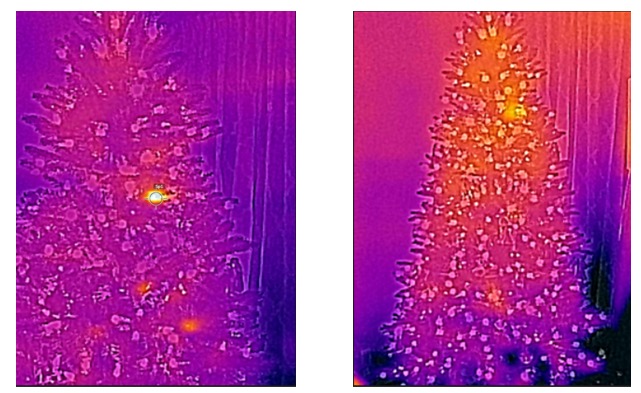

The very first Lepton product is the FLIR One. The FLIR One is a smartphone adapter that turns your iPhone (soon Android) into a thermal camera. This product is designed for the consumer electronic customer who would benefit from seeing in the dark or seeing something get hot or cold. For only $250, homeowners can now afford their own thermal imager, and have the ability to look for water leaks and missing insulation. It can be used outdoors to see if it is safe in a parking lot or in the woods. The applications are unlimited. Here is a recent example of the use of the camera. LED Christmas tree lights had a problem where there was excessive heat at the fuse.

Here is another simple application. When purchasing a beverage, have you ever wondered which one was coldest inside the refrigerated case? If you look at the picture in Figure 8 one milk bottle is clearly colder than the other. Well, now with the accessibility of the FLIR ONE you can.

FLIR AX8

The second product to have a Lepton detector in it is the FLIR Ax8. This is the first automation camera under $1,000. Combining thermal and visual cameras in a small, affordable package, the AX8 provides continuous temperature monitoring and alarming for uninterrupted condition monitoring of critical electrical and mechanical equipment.

The AX8 provides early detection of temperature-related issues in electrical and mechanical equipment, making it the ideal temperature sensor for continuous condition monitoring and hot spot detection for electrical cabinets, process and manufacturing settings, data centers, mass transit facilities, energy generation plants, and storage facilities

FLIR TG165

The third product to include the Lepton detector is the FLIR TG165. The TG165 is an infrared imaging spot thermometer. For years, customers have been using spot guns to affordably take non-contact temperature readings.

Spot guns have generally sold from $100 to $300 with some high temperature versions selling for over $1,500; however, a spot gun has several drawbacks. The first is its spot size ratio. Most spot guns are ill equipped to measure accurately from a distance. A typical 8:1 spot gun will measure a target 6 inches in diameter from 4 feet away. With this type of performance you are most likely to miss any problems that exist.

Since there is no image, the time it takes to use a spot gun is exceedingly long. Having to measure many spots on a typical target can take a lot of time. There is no way to record or document what you have found. Information is based on the measurement you see on the spot gun. The new TG165 reduces many of these challenges as FLIR has imbedded Lepton into the device to provide a two dimensional thermal image. It still uses the spot gun pyrometer to measure the temperature, but a standard .bmp image can be stored as well as shared by all personnel responsible for the imaged target.

Baby Monitor

Now that we see the first three products that can benefit from Lepton, a baby monitor is one household product that comes to mind. All visual baby monitors need some type of light amplification technology. The problem here is that if there is too much light it would be difficult for the baby to sleep. If there is not enough light, then the visual camera will not be able to produce a good image. Having a low cost thermal camera will allow for constant monitoring at all times. It would be much more comforting to the family if they can easily see the newborn baby sleeping in the crib.

Security Systems

Home security systems could also benefit from low cost thermal detectors. The home security system in a box does a very good job of providing security when you are out during daylight hours. But as the day turns to night, these security systems lose their effectiveness. Incorporating thermal imaging into these systems allows for constant home monitoring because at all times you will be able to see who comes and goes.

Automobiles

Major luxury brands automobiles have adopted thermal imaging as a driving assist tool. The technology is still relatively expensive and sold as an exclusive option. By lowering the detector cost the thermal imaging technology is accessible now on Ford, GM, and Honda, etc. The key benefit to the customer is safer driving at night. Infrared gives the driver about 5x further viewing than standard headlights. This increased visibility at night allows for faster reaction times to avoid animals, humans, and other road disasters.

Drones

Drones are so popular these days that there is speculation that they can one day deliver products that we order online. We are always getting questions on how to fit a thermal imager on a drone, for search and rescue, weatherization applications, utility line surveys, and even gas detection. Lepton-based cameras will be small and lightweight making them perfect for drones to use.

Conclusion

In summation, our industry has seen many changes since 1965. Most of those changes have happened when a new detector technology has changed the way manufacturers design their infrared cameras. The next generation of cameras will always be smaller, lighter, and more affordable. In fact, many of these cameras will not come from traditional camera manufacturers. This leads to accessibility and eventually, sometime in the future, everyone will have a thermal camera. That’s when this technology will truly be our sixth sense.