Successful Use of IR in Pest Management

Bart Bruni, Certified Pest Operator

Level 1 Thermographer

Bestec Exterminators

323 SE First Avenue

Hallandale Beach, FL 33009

954-458-1104

Abstract

The pest management industry has a growing need for infrared pest inspectors. A common standard in the pest industry recommended by the National Pest Control Association is Integrated Pest Management or IPM. The concept of IPM is finding and destroying insect nesting sites, as opposed to a broad application of insecticide to control infestations. Thermography and IPM are a perfect blend. This paper will discuss the nuts and bolts of inspecting for wood destroying organisms using IR and other non-destructive inspection methods.

Discussion

I would like to start by discussing why the success or failures of pest control operations are largely dependent on the inspection.

The inspection discloses the evidence that leads to:

-

Identification of the target pest

-

What varieties of insects are infesting a structure

-

Conditions that support the infestation such as moisture or lack of moisture

-

The location of suspected insect harborage areas

All of the above are necessary in designing a treatment strategy appropriate for the elimination or control of a target pest. Post treatment inspection is another important phase of the overall pest management of any infestation. Commonly referred to as a re-treatment inspection, this is the pest professional’s quality management program.

The authorities that govern the pest control industry endorse a concept called “Integrated Pest Management” (IPM) which suggests that we integrate environmental change that will affect the target pest, utilize the best detection and inspection methods that will lead to exact identification and precise chemical applications, thus “finding the nest and destroying it”, opposed to a broadband chemical application in the hope that the target pest will pass over the treated zone and become affected and die. Thermal imaging and pest management fit together nicely in three ways: inspection, treatment, and post treatment operations.

What is a pest?

Pests are living organisms that enter into a space where they are not wanted or that cause damage to crops, humans, animals or property. Examples include:

-

Wood destroying organisms

-

General household insects

-

Mice and other animals

-

Unwanted plant life

-

Wood destroying fungi

As you can see, there are many of different kinds of pests. The prudent thing to do is to find facts with your clients first and find out what’s concerning them. You may be surprised what they consider pests.

Pest ID

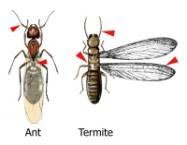

The pests best suited for detection with the help of infrared thermography are subterranean termites, ants, small critters and wood destroying fungi. Termites have a fat waist and four equally-sized wings, as opposed to ants which have a thin, defined waist and two equal sized wings.

Subterranean termites (Reticulitermes)

Subterranean termites are insects that live in the earth and enter structures from the ground up. They are dependant on returning to moist soil. The fact that both subterranean termites and ant colonies need moisture explains why the thermal signature you receive inside the structure looks much like water infiltration.

Eastern subterranean termites peeking out of a foraging tube

Formosan subterranean termites (Coptotermes Formosanus)

The Formosan subterranean termite is the most destructive termite on our planet. It infests the southern tip of the US with the exception of Nevada and New Mexico.

|

|

Carton Nest

Why is this termite a PMP’s nightmare?

-

These insects can secrete an acid that will dissolve building materials to get to wood

-

A colony can consume up to three pounds of wood per day

-

Twenty percent of all Formosan termite infestations have no contact with the ground, thus are very difficult to treat conventionally, and must be found and eliminated or the damage will continue

-

They utilize moisture within a structure to create above ground nests called “cartons” and are very aggressive in both their commitment to their feeding sites and to colony reproduction

-

A colony of these termites can have up to 20 million members, as opposed to the 1 million members of the termite native to the northeast US

|

|

|

|

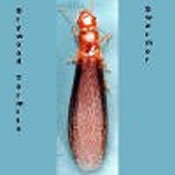

Drywood termite swarmer

|

Drywood termite droppings

|

Exit hole

|

Drywood termites (Cryptotermes Brevis)

Drywood termites have no association with soil and the colony lives in wood. Ideal moisture conditions for these termites is no more than 16% to 18% moist wood, hence the name drywood termites. This termite is not aggressive; however, will systemically damage your property over time. The swarming of any termite species is their reproductive ceremony. The drywood termite swarms from wood that it has infested and lands on new wood to be infested. Twenty-four to sixty months later the new colony is ready to swarm as a result.

Wood destroying beetles such as the power post or old house borer beetles show evidence somewhat like drywood termites; however, the droppings are fine powder, and the exit holes appear in groups such as the pattern from a shot gun.

Behavioral evidence

Subterranean termites eat wood with the grain and leave a muddy mastic substance on the eaten wood, as opposed to drywood termites that eat wood across the grain and leave fecal droppings.

Carpenter Ants

Carpenter ants do not eat wood; however, they chew moisture affected wood and receive nutrients from the wood destroying fungi associated with wet wood. The evidence seen from that feeding is called ant frass, which is the debris that ants spit out after the fungi meal.

The Inspection

The protocol that we use to perform an effective IR pest inspection is as follows:

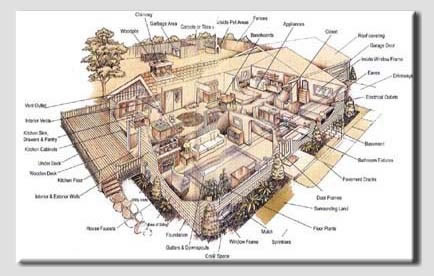

I would like to say that I strongly advise that the thermographer conducting a pest inspection is or should be accompanied by a licensed Pest Management Professional (PMP) experienced in the target pests you are inspecting for. Having said that, a visual inspection of all accessible areas should include the entire interior and exterior of the structure. Then, a graph is made of the structure on graph paper, denoting the areas of insect infestations, suspected infestations, past infestations, existing damage, foundation type, roof design, location of landscaping, inspection hot spots, linear feet, square feet, cubic feet, and other pertinent information such as areas conducive to insect infestations.

The manner we use to document our findings is to mark the walls, floors and ceilings with ultraviolet pens. We mark our findings directly on the site where the readings were taken. When necessary, we access that information with a handheld black light. During the visual inspection, the areas where evidence was discovered are called hot spots. Moving through each room in a clockwise pattern, we record the inspection on a digital camcorder which is interfaced with our IR imager. We capture black and white video

images and when anomalies are discovered, take a digital photo in the same field of vision, then capture images in a color palette. We document each site where IR images are captured on the graph, ambient temperature, humidity, wind speed, and dew point readings. In the areas where anomalies are found, we test for moisture with a nondestructive meter. Next, we check the anomaly with a motion detector and/or other nondestructive testing methods such as ultrasound, X-ray, and K-9. If the results are positive, we document the readings. We are now at a point in the inspection where invasive measures become necessary, such as a drilling a three-sixteenth inch in diameter entry hole for a fiber optic scope to confirm if live pests are present.

Arboreal Termites (Nasutitermes)

A new termite species has appeared in North America and was first discovered in the year 2001, in Dania Beach, Florida. This termite is not a drywood, subterranean, or a dampwood termite. The arboreal termite is a totally different category of termite, code name “tree termite”. In 2002, the USDA and Consumer Services funded a project called the “tree termite eradication program”.

|

Tree Termite Nest |

The red dots denote the nesting sites in this aerial photo |

Strategic operations were set up to eradicate this newly imported species to our country. I am proud to be serving my third year on the USDA eradication task force for tree termites.

The status of the eradication program of this pest is ongoing. IR was not employed as a tool for this program; however, IR can be used to assess the damage suffered by trees from wood destroying organisms.

Above image courstey of Termicam, www.termicam.com.au

These termites possess several unusual characteristics. First, they have the appearance of an ant more so than a termite; secondly they nest above ground in or around a structure.

These nests can get to be about the size of a basketball. Their foraging behavior is to build shelter tubes that are straight and high up into trees or into structures. The temperature of the shelter tubes that these termites construct is at or very close to ambient. This creates difficulty when using IR as an inspection tool; however, they are very visible to the human eye.

Warm Blooded Critters

Rodents, possum, squirrels, deer, etc. can be detected readily with IR. Snakes and large insects are the exception as it relates to small critters.

This snake’s body temp is approximately 37 degrees F making it appear cold in the above IR image.

Ants

These are difficult insects to deal with in pest management. This is due, in part, to the number of different varieties of ants that are indigenous to the site, of any given inspection, that you might not be aware of. For best results, locating and treating their colony is the preferable strategy. Ants, like most living things, need moisture. So, the areas of a structure that are above twenty percent moist with one hundred percent humidity would be a worthy place to perform an intense inspection with a Pest Management Professional (PMP). Infrared can speed this process up dramatically.

There are many factors to consider when conducting an ant inspection. Among these are factors such as pest identification, knowing a bit about insect behavior, the landscape around the structure, the type of ornamental plants that are close to the structure, plants and trees that touch or encroach upon the structure, the season and weather conditions in which the inspection is to be conducted.

The above are just a few of the many factors you would need to consider. As you can see, pest identification can be tricky. Department of Agriculture and Consumer Services (DACS) satellite offices are located in most cities in the US. If you find yourself in need of an accurate pest ID, I recommend that you collect a good sample and contact the DACS office closest to the location of your inspection for an exact ID.

Some benefits infrared thermography has to the PMP in all of the pest inspections mentioned above are that it saves time, creates good documentation, and can be used to pinpoint treatment sites not visible to the naked eye. IR is also useful when re-inspecting previously treated areas. IR, being a method of post-treatment documentation, will reduce a PMP’s liability. Having added IR to each phase of my pest control operation is what makes IR cost effective in my pest management business.

There are thermal patterns associated with eastern subterranean termites, Formosan subterranean variety, and the Caribbean subterranean termite (Coptotermes Havilandi). The most significant factor between termites and thermal patterns is that scientific research has proven subterranean termites seek specific feeding sites by temperature gradients. This information can be useful when inspecting for termites as well as when correcting infestations. All the above mentioned termites are serious wood destroying insects and are all very similar in behavior; however, on occasion some differences can be recognized.

The Eastern Subterranean termite’s above ground foraging habits are that they forage up in structures with their shelter tubes and then branch off laterally and continue to duplicate that pattern. Note the thickness of the shelter tube in the above photograph and thermograms. In the case of the Formosan termite, the thermal signature is different because the tubes are much thicker. These massive tubes are a characteristic common to the Formosan termite in South Florida.

Subterranean termites conserve water so well that one drop of water per day will sustain a carton with a population of up to one million termites.

The carton nest’s thermal signature when in a structural void appears much like water infiltration. For example, the Formosan termite will quickly take advantage of moisture sources in the structure. Thus, target areas for an IR inspection would be areas of the structure where moisture intrusion exists or is possible to exist, such as moisture from condensation, typical to A/C lines or bathtub drains, just to name a few. Eastern subterranean termites rarely create above ground carton nests. The signature for this termite is cool stripes in baseboards, door frames and moldings as well as very cool wall studs. Caribbean Subterranean termites have the same up and lateral foraging pattern and they create carton nests just as the Formosan variety; however, I have found that the Caribbean termite prefers to carton nest in wood beams that they have hollowed out as opposed to wall voids that are comprised of 90 degree angles.

IR is a great “where tool” as opposed to a “what tool”. Termite infestations discovered with IR should be used only as one leg of your diagnostic approach and should not serve as a stand alone means for termite identification.

When inspecting for drywood termites (DWT) or wood destroying beetles, thermal patterns are practically nonexistent – the galleries and the wood are the same temperature. The tools of choice for DWT and beetle inspections are experienced eyes and a flashlight. I have found that a terma trac microwave movement detector can be of great value when inspecting for these insects.

Active thermography can play a major role during the treatment of DWT. Infrared provides the direction for precise placement of materials. Compressed air or treatment materials mixed with hot or cold water can be used to create the delta T necessary for quality IR images. This thermal material, when injected into the DWT or beetle exit holes, will fill up the galleries that the insects have hollowed out in the wood. This protocol creates precise placement of treatment materials which leads to safer use of pesticides. This type of documentation can be helpful when discussing with your client the successful treatments the PMP performed to their property, and particularly if reviewed at contract renewal time, will increase the PMP’s customer retention rate.

In other pest inspections such as wildlife pest inspections, IR has been a helpful tool in the answer to some often asked questions such as “what is eating my garden and how is it getting on my property?” IR surveillance cameras with monitors work great. The last system I designed for a client produced useful evidence to correct their pest problem.

Mold

A by-product to the IR inspection provides your client with information about where possible mold and insect affected areas are located. Identifying the areas that are over twenty percent moist in a structure is relevant to pest management and the IPM concept. If steps are taken by the owner of the property to correct moisture intrusion based on our inspection report, it will have a positive affect on preventing insect infestation, mold, and wood destroying organisms such as termites and wood fungi.

Thermography has increased my professional image and has been a beneficial tool in managing my liability. The power of images in pest management is awesome. IR has easily provided my clients with images of the initial infestation prior to treatment, images taken during the treatment, then ten weeks after treatment. This equates into proof of treatment success or failure. I have also found that IR images reassure my clients that structural members such as attic rafters, wall studs and support beams are still in place, which can be a big relief as it relates to Formosan termites.

Electric Current & Termites

There is an unexplained phenomenon that some of my peers and I have noticed over the years while inspecting for termites – subterranean termites have an association with electric current.

Fact:

Theory:

It may be that the CO2 gases emitted from electrical systems feel similar to what termite sensory perception receives from decomposing wood or evaporating water. All is unproven; however, with this observation in mind, electrical systems are included in the protocol for inspections that I conduct.

In the Spring of 2002, early detection of termites saved the US Department of Homeland Security compound in Fort Lauderdale, Florida from a communications system nightmare. In this case, the three-quarter inch thick, four foot by eight foot plywood boards that their phone equipment was mounted onto, had shown evidence of a Formosan termite infestation. If that plywood had been eaten, it is obvious that it would have been an inconvenient, timely and costly repair. Including termite inspections with electrical inspections is something you may want to consider, particularly in the southern part of the US. There is not much involved on your end – you just need to inspect the wood the gear is mounted to. This can provide valuable information to your client and can project your genuine concern for your client’s or employer’s best interest.

Conclusion

Recent developments using termite DNA testing to identify colonies present a need to increase the inspection protocol for initial and post-treatment inspections. It is likely that insecticide manufacturers will include inspection requirements listed on their product labels. As per federal law, PMP’s must adhere to the manufacturers label requirements. This would create a need for better inspection tools and certified personnel to meet the label requirements for the pest industry.

Currently, the standard inspection practice for termites is once per year unless there is a termite episode discovered by the client. New chemical manufacturer’s labeling requirements may state that the structures will require frequent inspection schedules such as the initial inspection plus a post-treatment inspection seven, fourteen, and thirty days after treatment and then follow up inspections every 90 days thereafter. If, in the future, inspections are not required by a chemical manufacturer’s label, adapting to this inspection protocol will save the PMP field time, chemical cost, and increases the renewal retention, which provides great value to the PMP. The increased data that is disclosed by hi-tech non-destructive inspection equipment will lead to treatment strategies that focus more on the value of inspections, as opposed to treatment strategies that are mostly chemically dependent.

I speak for myself and many PMP company owners who are just realizing the benefits of infrared thermography; we welcome thermographers who are interested in joining the pest control industry. For those thermographers who are up for this calling, I will leave you with some useful information about how to begin prospecting in this market. Pinpoint your marketing champion at medium-sized termite and pest companies that have high end clients. Propose your services to them in a manner that points out all the areas mentioned above where IR can make or save the PMP money. Visit our web sites for additional pest information at www.bestecexterminators.com and www.spectrumIR.com.

Advertisement