Setting Temperature Limits

Sponsored by:

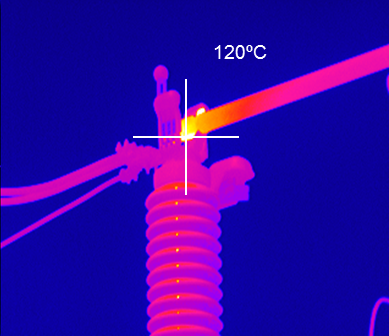

Over the past thirty years, a number of temperature severity guidelines have been published by various organizations. When using these guidelines, you may compare similar components under similar load to each other OR compare the subject component to ambient. The former of these approaches is recommended since ambient temperature can swing widely over time. Furthermore, it is often impossible to obtain an accurate ambient temperature for devices located within an enclosure once the enclosure has been opened for the infrared inspection.

One of the most conservative temperature guides can be found in the Standard for Maintenance Testing Specifications, published by the InterNational Electrical Testing Association, Portage, Michigan. According to the NETA MTS, temperature differentials greater than 15° C are categorized as, “Major discrepancy; repair immediately”.

Other organizations publish less conservative temperature guidelines than the NETA MTS. Some guides require delta T’s of 70°C or higher to qualify as items of immediate concern. When setting temperature limits, one should remember that temperature differentials cannot be utilized to predict time to failure for an electrical device. Therefore, all thermal anomalies detected during an infrared inspection should be investigated and proper corrective measures undertaken as soon as possible.

Setting temperature limits and prioritizing exceptions for electrical and mechanical equipment are two of the many topics covered in the Level II Infraspection Institute Certified Infrared Thermographer® training course. For information on thermographer training or to obtain a copy of the Standard for Infrared Inspection of Electrical Systems & Rotating Equipment, visit us online at www.infraspection.com or call us at 609-239-4788.

Advertisement